Preparation method for electrode modified material of silver indium disulphide/reduced graphene oxide and application thereof for detecting ciprofloxacin

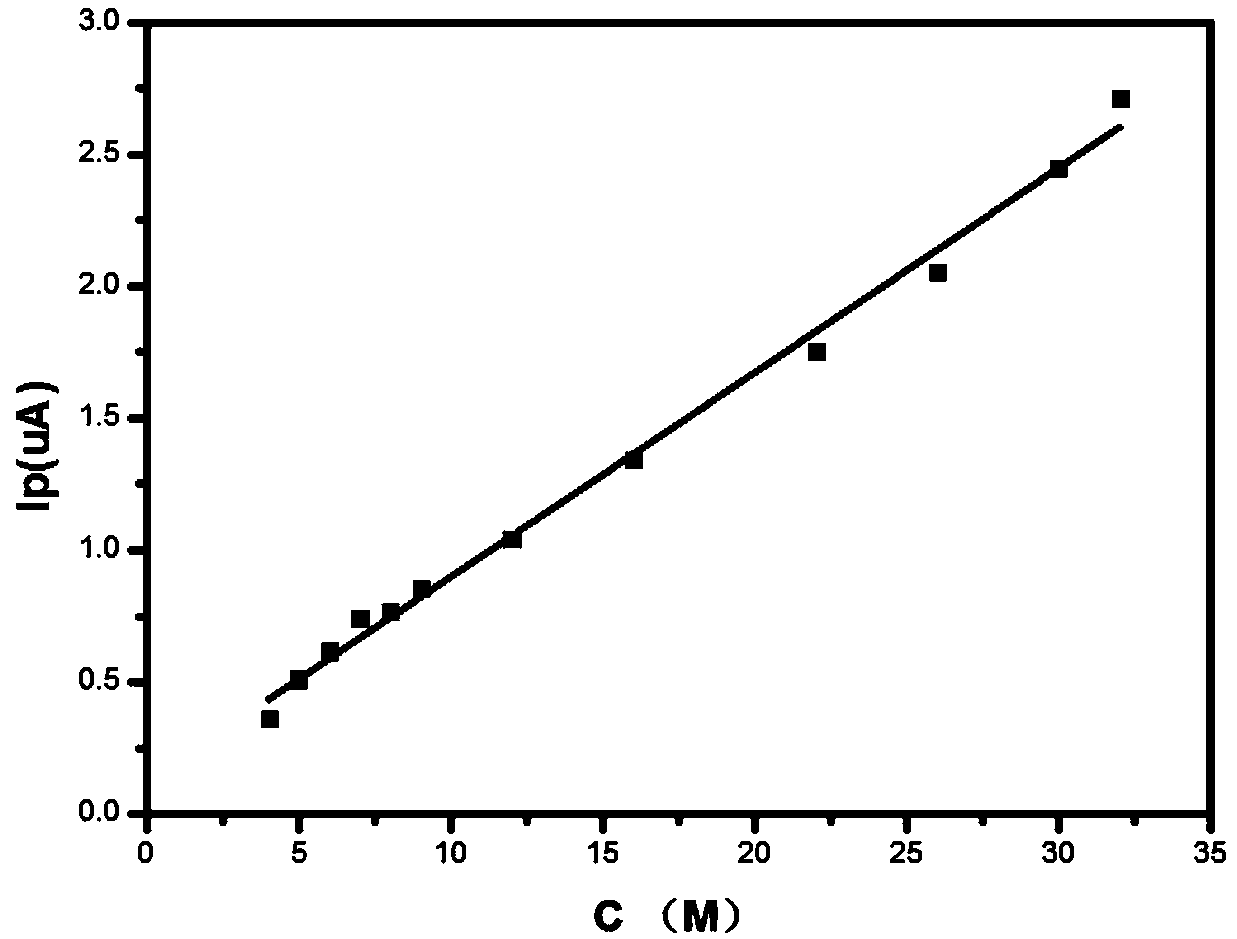

A silver disulfide indium and electrode modification technology, which is applied in the direction of material electrochemical variables, chemical instruments and methods, and material analysis through electromagnetic means, can solve the problems of expensive, complex technology and equipment, and achieve low detection limits, Low cost, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Graphene oxide (GO) was prepared by modified Hummer's method.

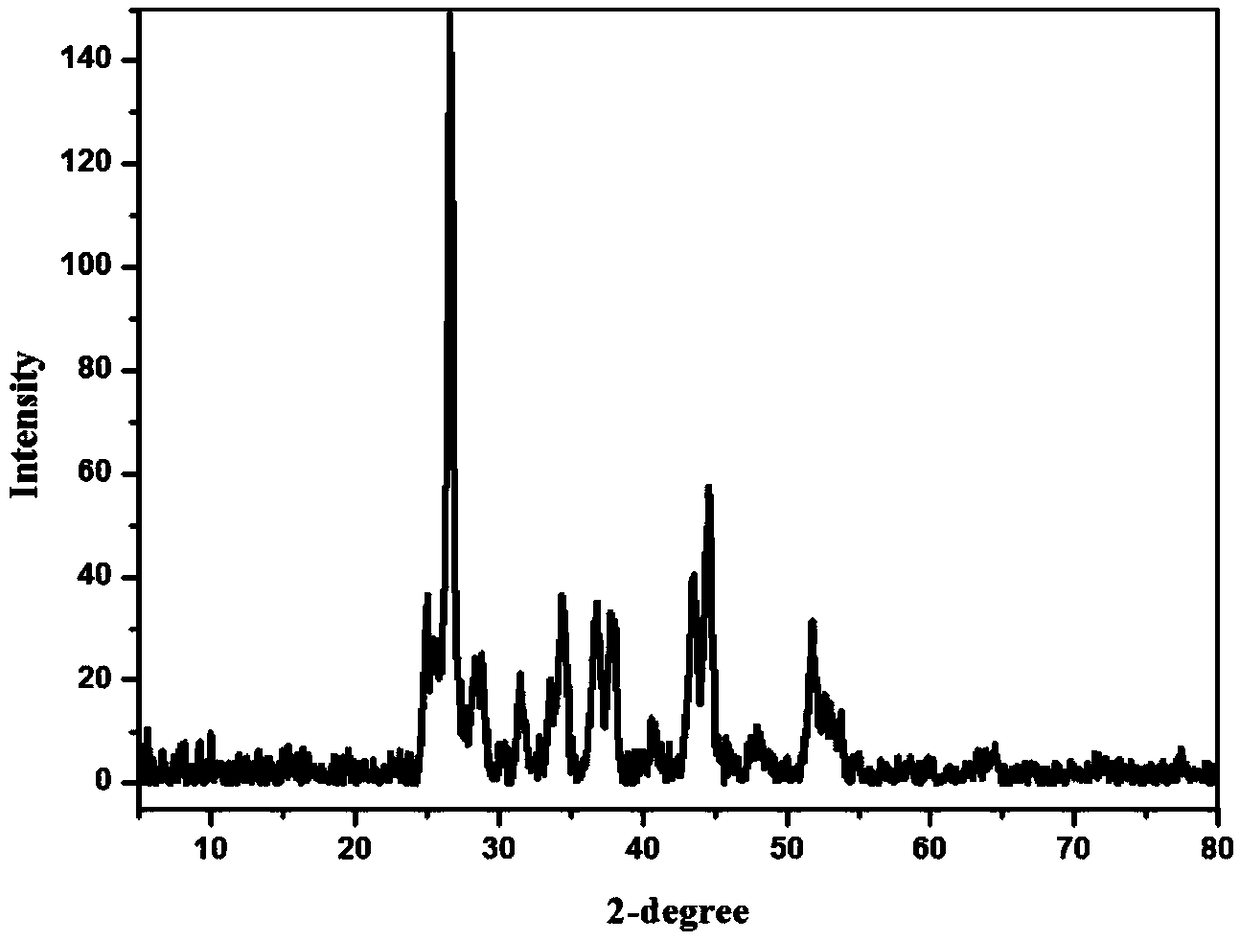

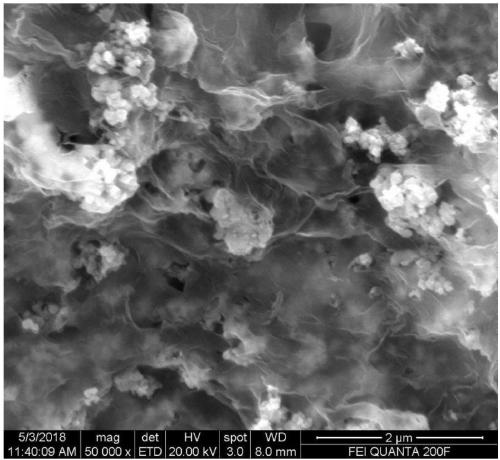

[0025] Preparation of AgInS by precipitation method 2 , specifically: take 0.0012mol AgNO 3 Dissolve in 50mL ethylene glycol, add 0.0054mol InCl dropwise under stirring 3 4H2O, stirred for another 10 min, then added 0.75 g of thioacetamide under stirring. After continuous stirring for about 1 h, the above solution was transferred to a 100 mL three-neck flask and refluxed for 3 h. After the reaction was completed, the cloudy solution was naturally cooled to room temperature and aged for 12 h. The resulting solid was collected by filtration and washed alternately with absolute ethanol and deionized water. Finally, the product was dried in a vacuum oven for 12 hours and ground to obtain AgInS 2 Material.

[0026] By ultrasonic dispersion method, GO was prepared into a 4.3 mg / ml dispersion liquid with deionization, and 30 mL of ethylene glycol was taken, and 9.3 mL of the above-mentioned GO dispersion liq...

Embodiment 2

[0029] Graphene oxide (GO) was prepared by modified Hummer's method.

[0030] Preparation of AgInS by precipitation method 2 , specifically: take 0.0012mol AgNO 3 Dissolve in 50mL ethylene glycol, add 0.0054mol InCl dropwise under stirring 3 4H 2 0, then stirred for 10min, then added 0.75g thioacetamide under stirring. After continuous stirring for about 1 h, the above solution was transferred to a 100 mL three-neck flask and refluxed for 3 h. After the reaction was completed, the cloudy solution was naturally cooled to room temperature and aged for 12 h. The resulting solid was collected by filtration and washed alternately with absolute ethanol and deionized water. Finally, the product was dried in a vacuum oven for 12 hours and ground to obtain AgInS 2 Material.

[0031] GO was made into a 4.3mg / ml dispersion with deionization, 30mL of ethylene glycol was taken, and 9.3mL of the above-mentioned GO dispersion was added under stirring. Weigh 20mg AgInS 2 , made a sol...

Embodiment 3

[0034] Graphene oxide (GO) was prepared by modified Hummer's method.

[0035] Preparation of AgInS by precipitation method 2 , specifically: take 0.0012mol AgNO 3 Dissolve in 50mL of ethylene glycol, add 0.0054mol InCl3·4H2O dropwise under stirring, stir for another 10min, then add 0.75g of thioacetamide under stirring. After continuous stirring for about 1 h, the above solution was transferred to a 100 mL three-neck flask and refluxed for 3 h. After the reaction was completed, the cloudy solution was naturally cooled to room temperature and aged for 12 h. The resulting solid was collected by filtration and washed alternately with absolute ethanol and deionized water. Finally, the product was dried in a vacuum oven for 12 hours and ground to obtain AgInS 2 Material.

[0036] GO was made into a 4.3mg / ml dispersion with deionization, 30mL of ethylene glycol was taken, and 9.3mL of the above-mentioned GO dispersion was added under stirring. Weigh 80mg AgInS 2 , made a solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com