Device and method for testing anti-slip performance of mine hoisting friction lining

A friction lining and testing device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inability to accurately evaluate the wear pattern of the friction lining, the inability to test the friction lining uniformly, and the difficulty of high-speed sliding friction, etc., to achieve The effect of good test effect, wide practicability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

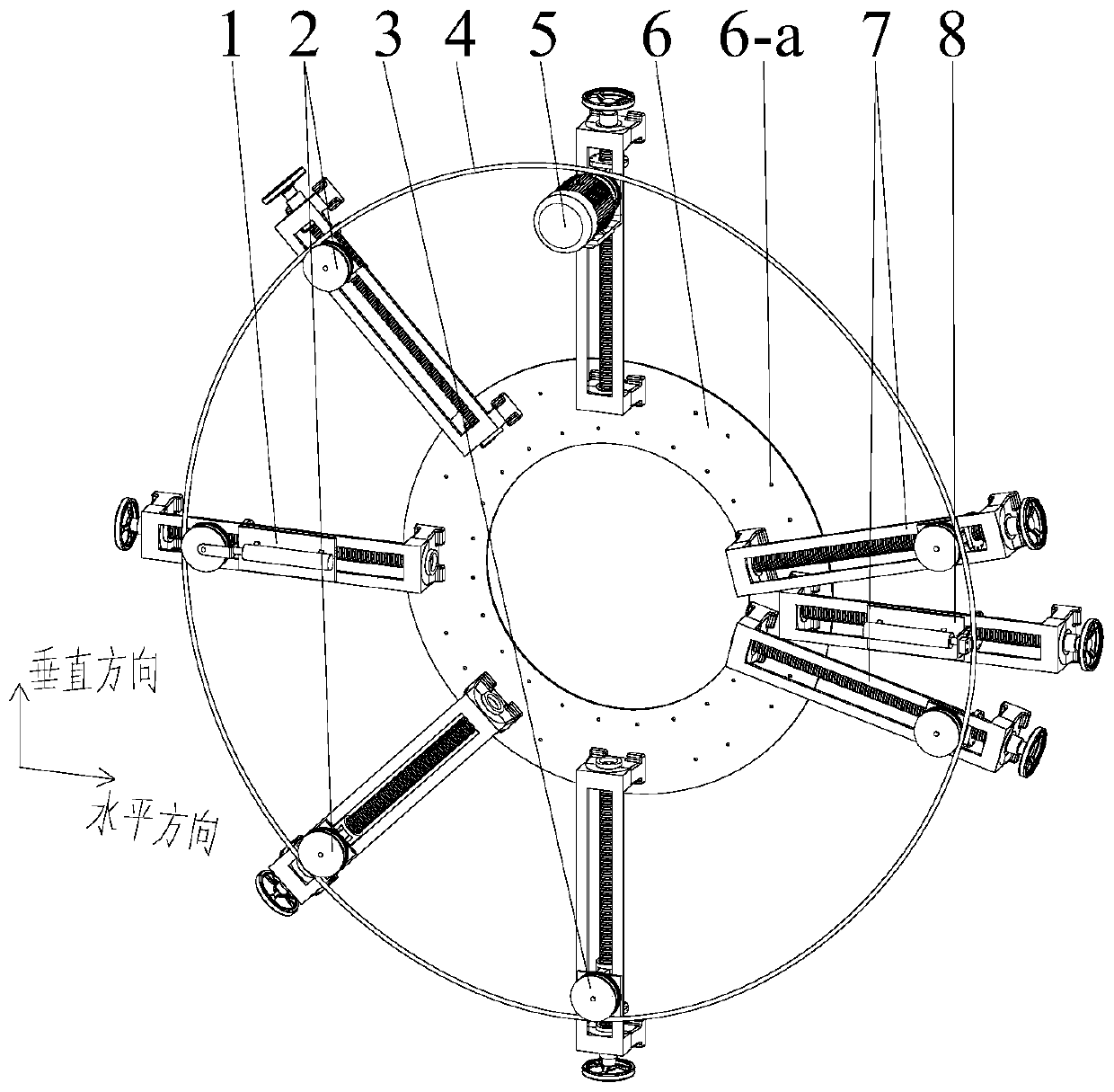

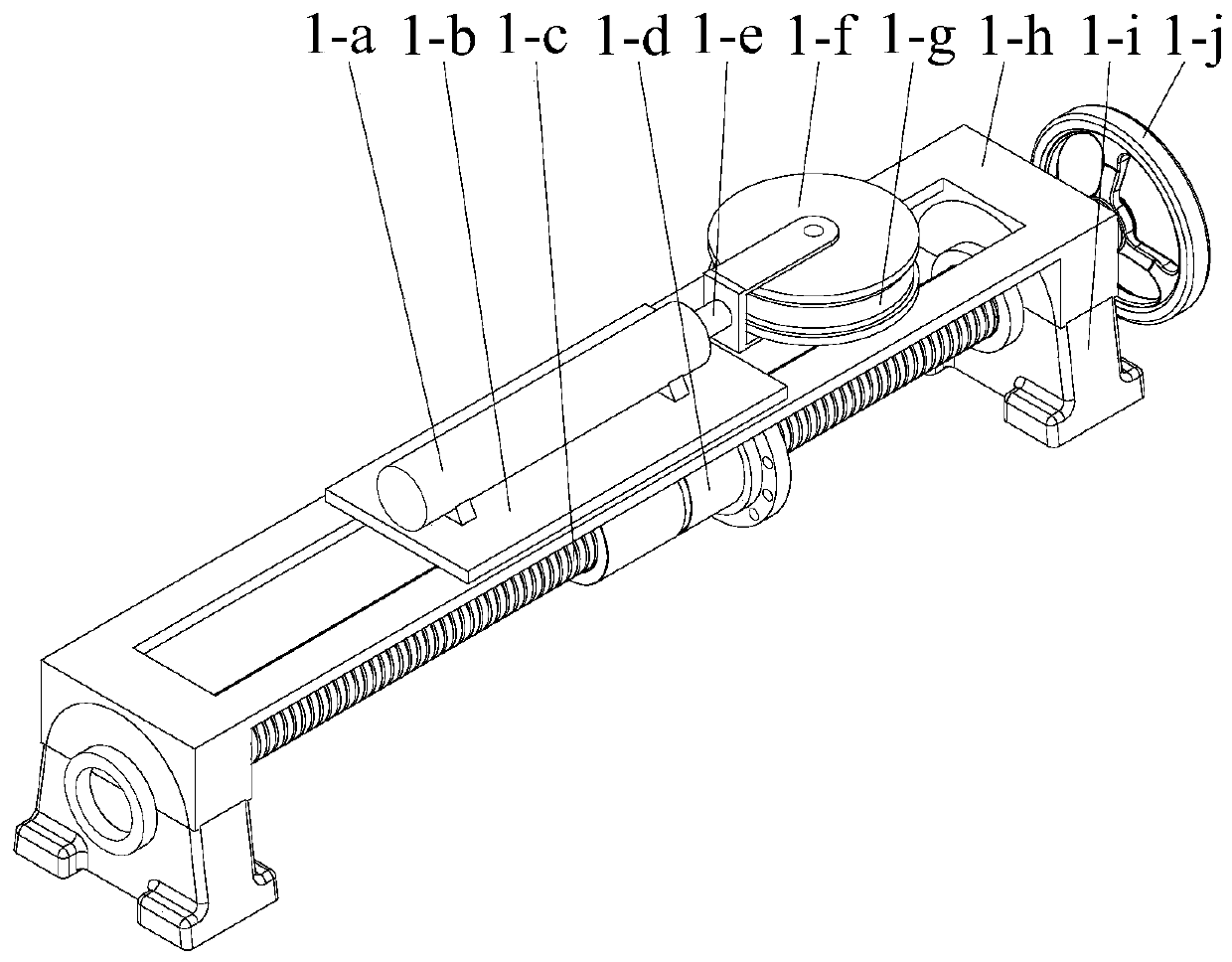

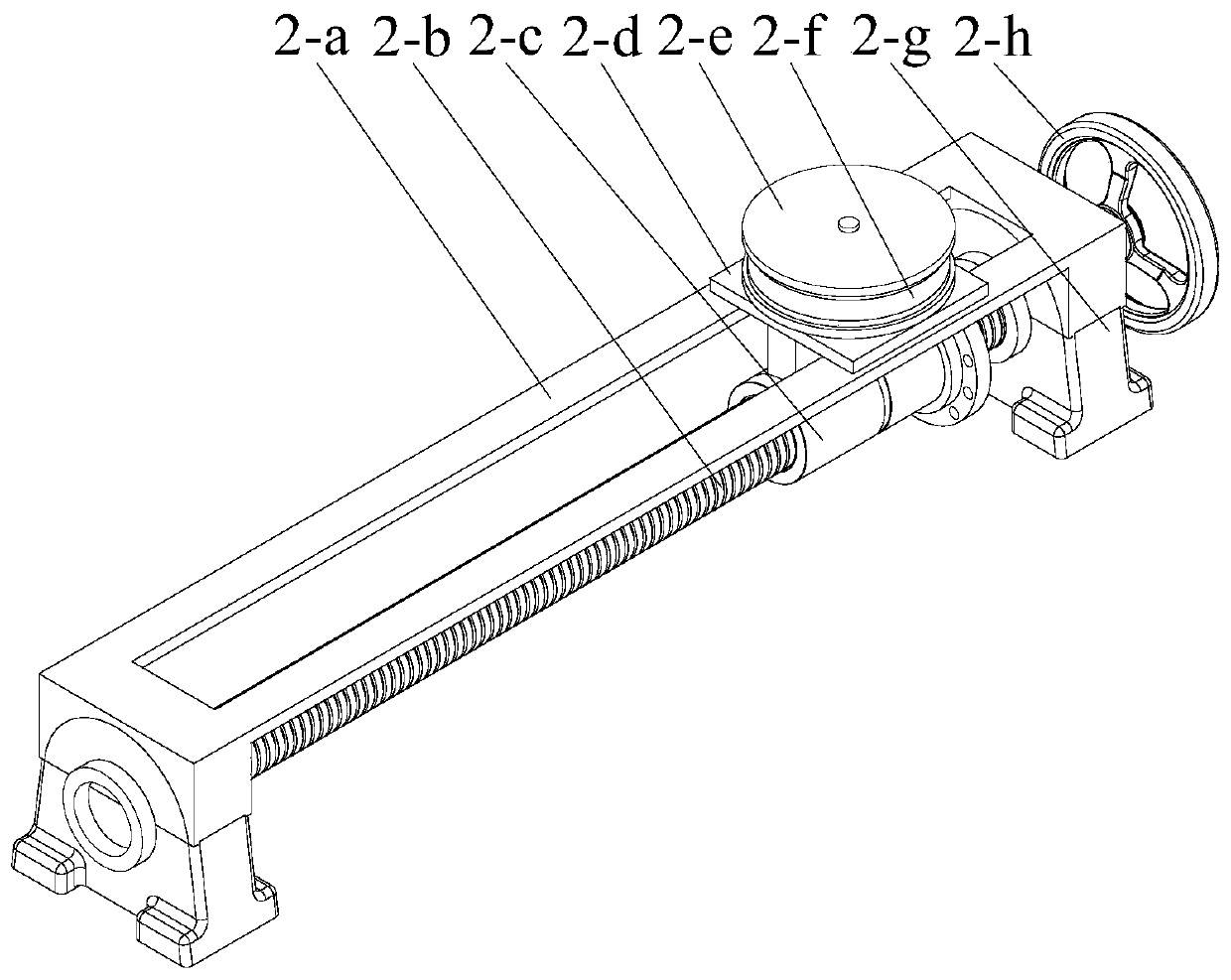

[0031] like figure 1 As shown, a mine lifting friction lining anti-skid performance testing device of the present invention mainly consists of a positioning platform 6, a tension loading device 1, two tension positioning devices 2, a wire rope limiting device 3, a wire rope dragging device 5, two The radian positioning device 7 and the liner loading device 8 are formed. The positioning platform 6 is provided with several rows of positioning holes 6-a arranged in a circle, the tension loading device 1, the tension positioning device 2, the wire rope limit device 3, and the wire rope dragging device. The device 5, the radian positioning device 7 and the pad loading device 8 are arranged on the positioning platform 6 along the circumferential direction through the positioning hole 6-a, wherein the tension loading device 1 and the pad loading device 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com