Natural based radiation curing material and application thereof in film coating UV adhesive

A radiation-curing, natural-based technology, used in adhesive types, ester copolymer adhesives, modified epoxy resin adhesives, etc., to achieve the effects of controllable reaction, high bonding strength, and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

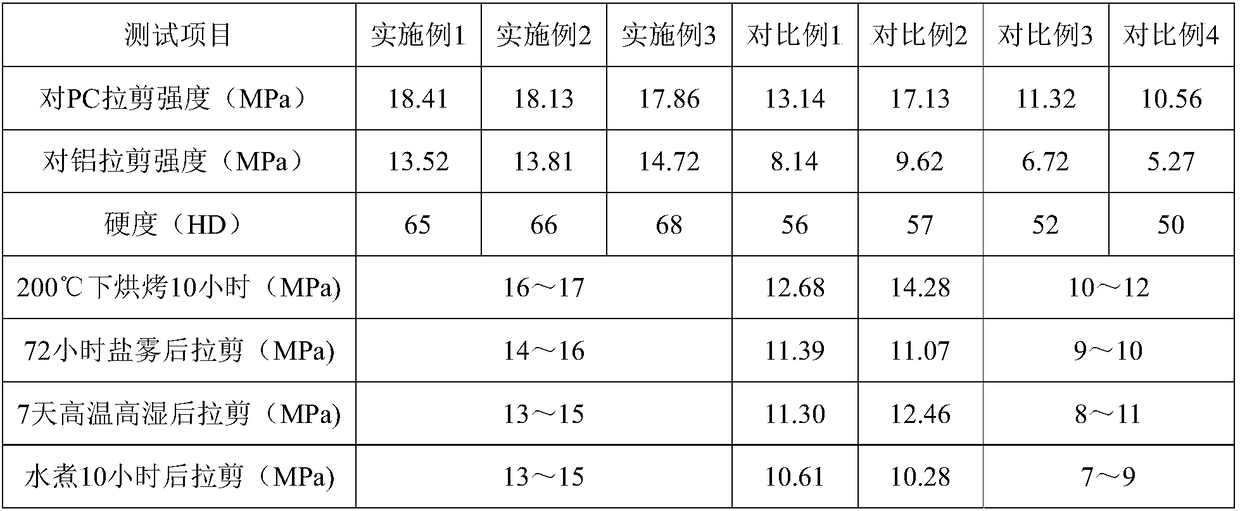

Examples

Embodiment 1

[0026] The components in parts by weight of the natural-based radiation curing material are: 41 parts of epoxy soybean oil modified water-based polyurethane, 8 parts of epoxy acrylate, 12 parts of polyacrylate, 25 parts of isooctyl acrylate, hexanediol diacrylate 18 parts, 15 parts of trimethylolpropane triacrylate, 3 parts of dibenzoyl.

Embodiment 2

[0028] The components in parts by weight of the natural-based radiation curing material are: 50 parts of epoxy soybean oil modified water-based polyurethane, 4 parts of epoxy acrylate, 7 parts of polyacrylate, 21 parts of isooctyl acrylate, hexanediol diacrylate 15 parts, trimethylolpropane triacrylate 10 parts, benzophenone 2 parts.

Embodiment 3

[0030] The components in parts by weight of the natural-based radiation curing material are: 45 parts of epoxy soybean oil modified water-based polyurethane, 5 parts of epoxy acrylate, 10 parts of polyacrylate, 22 parts of isooctyl acrylate, hexanediol diacrylate 16 parts, 12 parts of trimethylolpropane triacrylate, 2 parts of dibenzoyl.

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com