Compound shielding material containing MOF derivative porous gadolinium oxide and preparation method

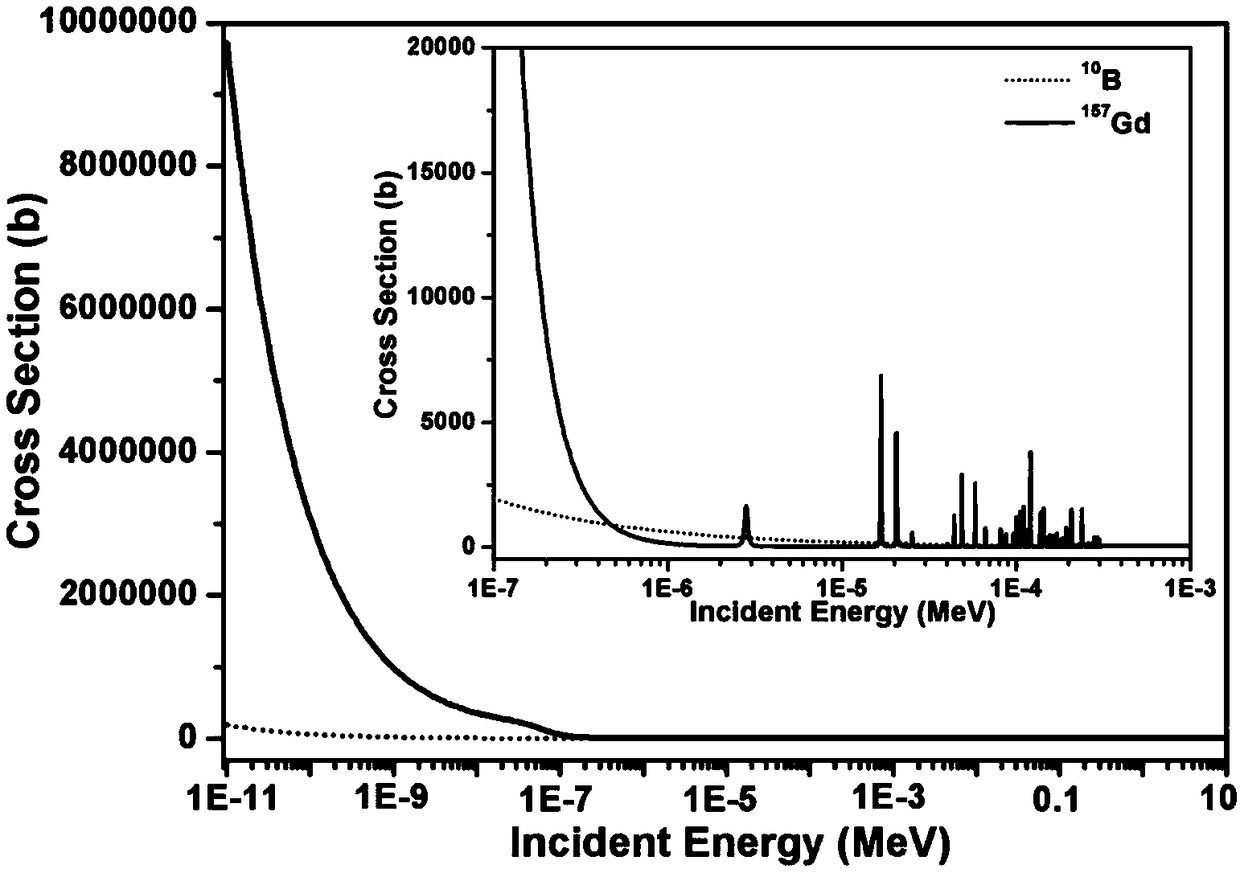

A compound shielding and gadolinium oxide technology, which is applied in the field of radiation shielding materials and nuclear radiation protection, can solve problems such as difficulty in increasing rare earth content, and achieve excellent mechanical properties, superior chemical corrosion resistance, and high hardness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

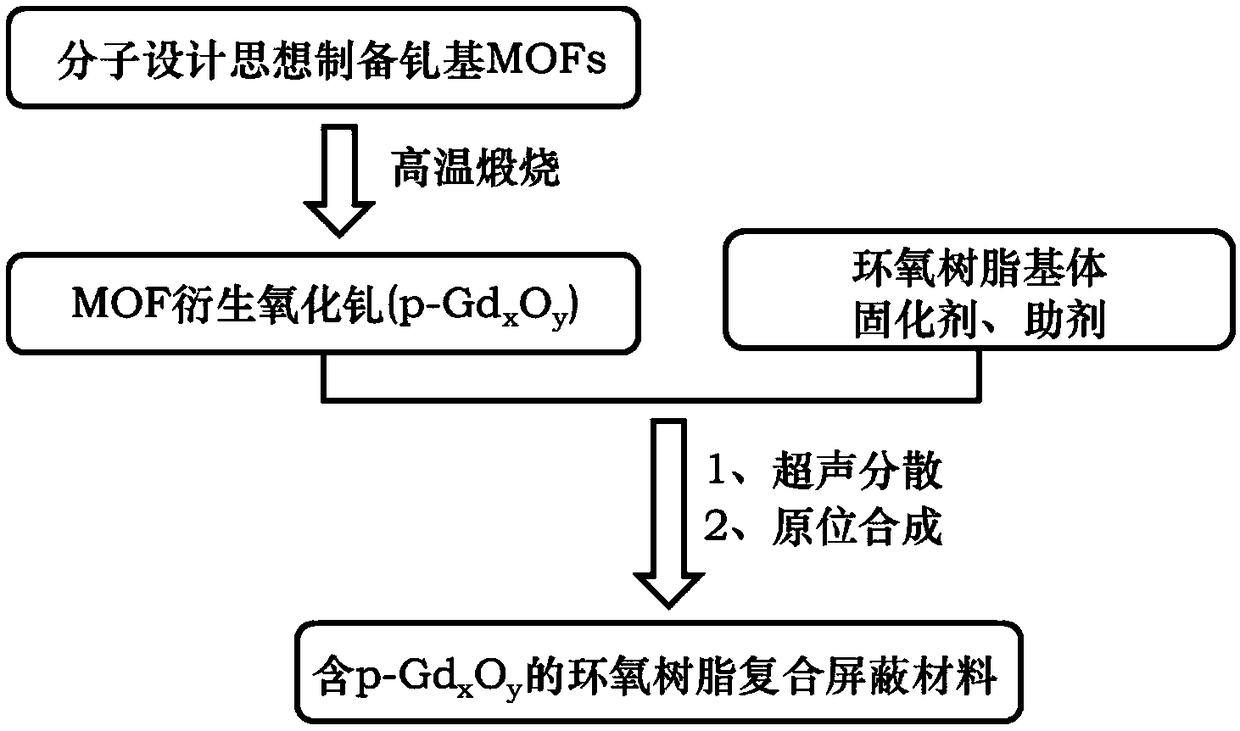

[0034] According to attached figure 2 According to the process, the epoxy resin-based composite shielding material is prepared step by step.

[0035] 1) Synthesis of Gd(BDC) 1.5 (H 2 O) 2 : select GdCl 3 ·6H 2 O and methylamine terephthalate as reaction raw materials, weighed 2.0g of polyvinylpyrrolidone and dissolved it in 16mL of deionized water, and added 92mL of GdCl with a concentration of 0.15M in sequence 3 ·6H 2 O aqueous solution and 92mL of 0.2M aqueous solution of methylamine terephthalate were placed in an ultrasonic instrument (frequency 40KHz), at room temperature, ultrasonically filtered for 0.5h, and washed several times with deionized water, at 60°C Collect Gd(BDC) by vacuum drying 1.5 (H 2 O) 2 powder samples.

[0036] 2) p-Gd 2 o 3 Preparation: Weigh an appropriate amount of Gd(BDC) 1.5 (H 2 O) 2 The material was placed in a muffle furnace and calcined at 600°C for 5 hours in an air atmosphere, and samples were collected. Its chemical compos...

Embodiment 2

[0044] 1) Synthesize Gd (BDC) according to the experimental procedure of Example 1 1.5 (H 2 O) 2 .

[0045] 2) p-Gd 2 o 2.8 Preparation: Weigh an appropriate amount of Gd(BDC) 1.5 (H 2 O) 2 The material was placed in a muffle furnace and calcined at 600° C. for 5 h in a nitrogen atmosphere, and samples were collected. Its chemical composition is proved by powder X-ray diffraction test, and the p-Gd is proved by nitrogen adsorption and desorption test 2 o 2.8 The multi-level channels with interspersed micropores and mesopores are verified by scanning electron microscopy, and their morphology features inherit Gd(BDC) 1.5 (H 2 O) 2 Due to insufficient oxygen during calcination, the final structural formula of gadolinium oxide is p-Gd 2 o 2.8 .

[0046] 3) p-Gd 2 o 2.8 Preparation of composite shielding material with epoxy resin:

[0047] Epoxy resin (JEh-041): 50 parts by weight

[0048] Curing agent (methyltetrahydrophthalic anhydride): 3 parts by weight

[00...

Embodiment 3

[0053] 1) Synthesis of Gd(BTC)(H 2 O) 4 : select GdCl 3 ·6H 2 O and trisodium 1,2,4-benzenetricarboxylate are the raw materials for the reaction. First prepare two parts of microemulsion 200mL of 0.5M cetyltrimethylammonium bromide / n-hexanol / pentane (volume ratio 1:15), then add 2.7mL of 0.05M 1 , an aqueous solution of trisodium 2,4-benzenetricarboxylate and 2.7 mL of 0.05M GdCl 3 ·6H 2 O aqueous solution was stirred separately for 10 minutes to form a transparent and uniform liquid; the two microemulsions were mixed, and stirring was continued for 8 hours to obtain a light blue emulsion containing the final product. The sample was recovered by centrifugation, washed with ethanol, and dried to collect Gd(BTC)(H 2 O) 4 powder samples.

[0054] 2) p-Gd 2 o 3 Preparation: Weigh an appropriate amount of Gd(BTC)(H 2 O) 4 The material was placed in a muffle furnace and calcined at 700°C for 5 hours in an air atmosphere, and samples were collected. Its chemical composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com