Temperature-sensitive up-conversion system and its preparation method and application in the preparation of temperature sensors

A temperature-sensitive and systematic technology, applied in thermometers, chemical instruments and methods, thermometers with physical/chemical changes, etc., can solve the problem of easy quenching, oxygen sensitivity, and temperature sensitivity and temperature sensing that cannot be achieved by up-conversion solutions. and other problems to achieve the effect of reducing the excitation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

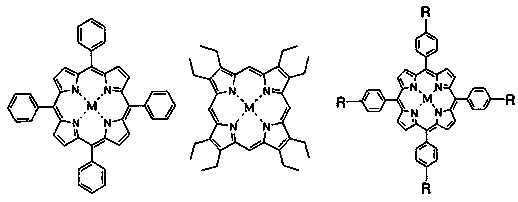

[0029] The organic solvent used in the up-conversion solution in this example is toluene, the photosensitizer is palladium octaethylporphyrin (PdOEP), and the luminescent agent is 9,10-diphenylanthracene (DPA). The structures of the two are as follows:

[0030]

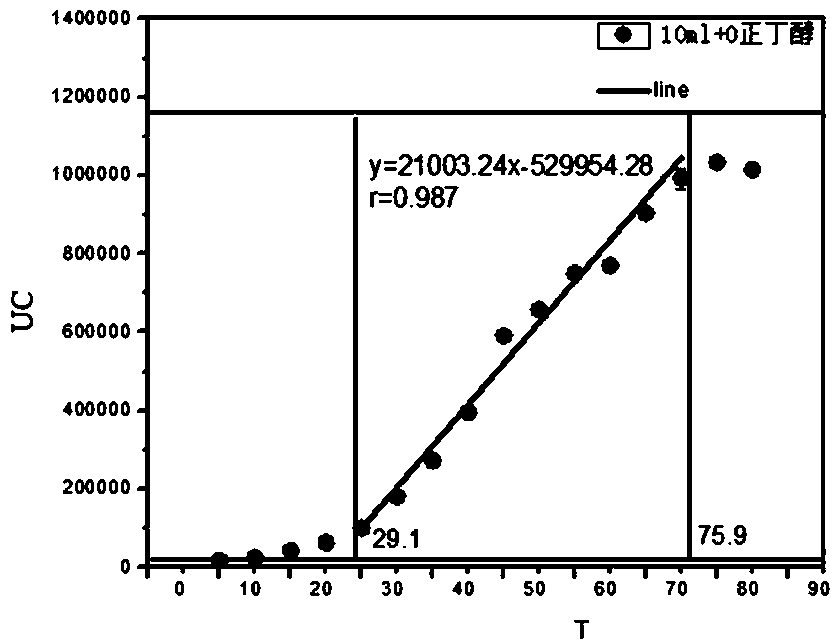

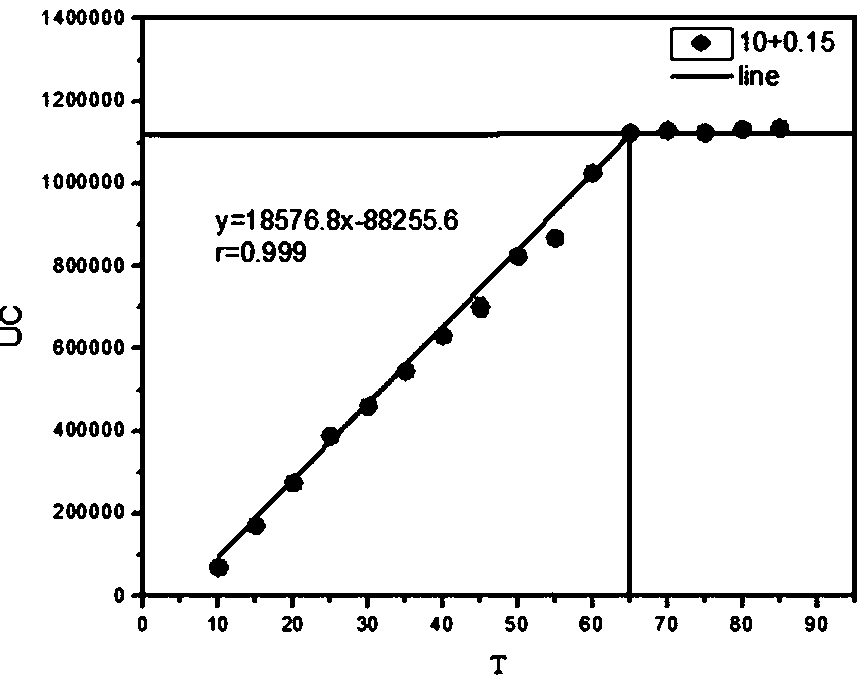

[0031] The surfactant used was Tween-20, the concentration of luminescent agent was 0.015 mol / L, the molar ratio of luminescent agent to photosensitizer was 300:1, and the volume ratio of deionized water to Tween-20 was 2:1. The mixed solution of 10ml Tween-20 and 20ml deionized water was placed in a nitrogen atmosphere and stirred to make it completely deoxygenated, and then 2ml containing photosensitizer PdOEP (5×10 -5 mol / L) and the toluene solution of luminescent agent DPA (0.015mol / L) to obtain a sample; get 5ml of this sample, add 0.02ml n-butanol, and obtain the up-conversion material after stirring. In a heatable environment, in a weak light field (light intensity 60 Mw / cm -2 , excitation wavelength is 532...

Embodiment 2

[0033] The photosensitizer and luminescent agent used in the up-conversion solution in this embodiment are the same as those in Embodiment 1.

[0034] The surfactant used is Tween-20, the organic solvent is toluene, the concentration of luminescent agent is 0.015 mol / L, the mol ratio of luminescent agent and photosensitizer is 300:1, and the volume ratio of deionized water and Tween-20 is 2: 1. The mixed solution of 10ml Tween-20 and 20ml deionized water was placed in a nitrogen atmosphere and stirred to make it completely deoxygenated, and then 2ml containing photosensitizer PdOEP (5×10 -5 mol / L) and the toluene solution of luminescence agent DPA (0.015mol / L), obtain sample. Take 5ml of this sample, add 0.05ml of n-butanol, and stir well to obtain up-conversion materials with different temperature response ranges (surfactant is Tween-20, and low-chain alcohol is n-butanol). In a heatable environment, in a weak light field (light intensity 60 Mw / cm -2 , the excitation wavel...

Embodiment 3

[0039] The photosensitizer used in this example is platinum octaethylporphyrin (PtOEP), and the luminescent agent is anthracene (An). The structures of the two are as follows:

[0040]

[0041] The surfactant used is Tween-20, the organic solvent is toluene, the concentration of luminescent agent is 0.015 mol / L, the mol ratio of luminescent agent and photosensitizer is 300:1, and the volume ratio of deionized water and Tween-20 is 2: 1.4. The mixed solution of 14ml Tween-20 and 20ml deionized water was stirred in an atmosphere of nitrogen to make it completely deoxygenated, and then 2ml containing photosensitizer PtOEP (5×10 -5 mol / L) and luminescent agent An (0.015mol / L) in toluene. Take 5ml of this sample, add 0.02ml of isobutanol, and stir well to obtain up-conversion materials with different temperature response ranges (surfactant is Tween-20, and low-chain alcohol is isobutanol). In weak light field (light intensity 60 Mw / cm -2 , the excitation wavelength is 532nm),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com