A method for recovering methyl tert-butyl ether in pharmaceutical process waste liquid by extractive distillation-adsorption coupling process

A technology of extraction and distillation of methyl tert-butyl ether, which is applied in the fields of ether preparation, chemical industry, ether separation/purification, etc. It can solve the problems of unavoidable, affecting the quality of intermediate E2, difficult recovery, etc., and achieve energy saving , Save equipment investment and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

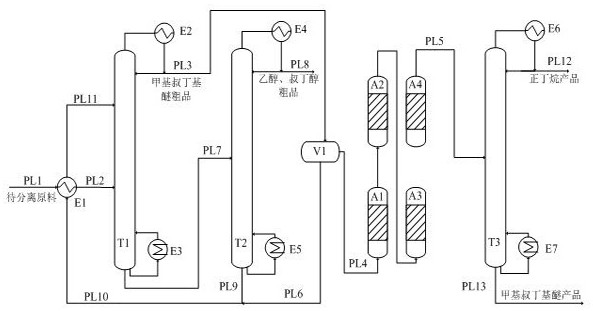

[0033] use figure 1 In the process flow shown, the body material of the extractive distillation tower T1 is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 1200mm, the number of theoretical plates is 32, and the extraction agent is fed from the sixth theoretical plate, the pharmaceutical process Waste liquid is fed from the 21st theoretical plate. Extractant recovery tower T2 tower body material is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 500mm, the number of theoretical plates is 24, and the 14th theoretical plate is fed. The body material of the n-butane separation tower T3 is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 600mm, the number of theoretical plates is 30, and the 13th theoretical plate is fed. Adsorption and dehydration towers A1~A4 are made of SUS304, with a tower diameter of 1200mm and a height of 3000mm. There are 503 DN38 tubes installed i...

Embodiment 2

[0037] use figure 1 In the process flow shown, the body material of the extractive distillation tower T1 is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 1200mm, the number of theoretical plates is 32, and the extraction agent is fed from the sixth theoretical plate, the pharmaceutical process Waste liquid is fed from the 21st theoretical plate. Extractant recovery tower T2 tower body material is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 500mm, the number of theoretical plates is 24, and the 14th theoretical plate is fed. The body material of the n-butane separation tower T3 is SUS304, the tower is filled with BX regular wire mesh packing, the tower diameter is 600mm, the number of theoretical plates is 30, and the 13th theoretical plate is fed. Adsorption and dehydration towers A1~A4 are made of SUS304, with a tower diameter of 1200mm and a height of 3000mm. There are 503 DN38 tubes installed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com