Preparation method for benzyl alcohol

A technology of benzyl alcohol and benzaldehyde, which is applied in the field of preparation of benzyl alcohol, can solve the problems of large investment, high requirements for production equipment, and unsafety, and achieve the effect of simple process and avoiding the use of hydrogen and pressurized equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

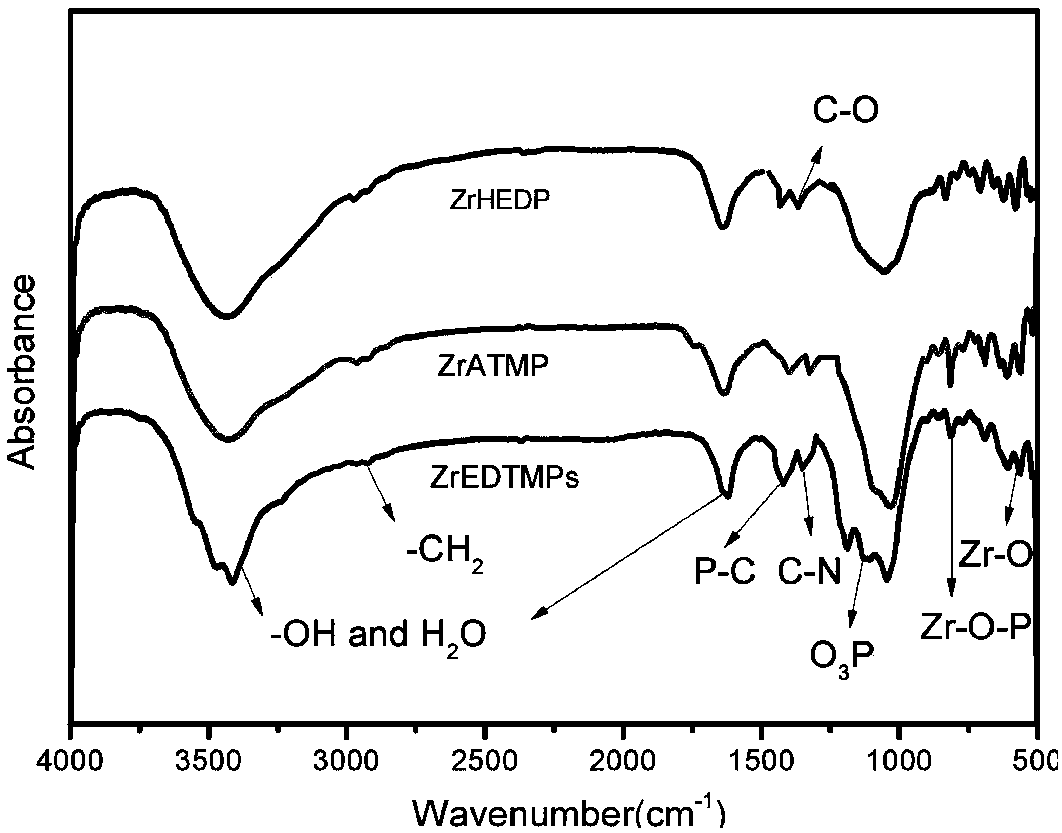

[0027] Preparation of zirconium hydroxyethylidene diphosphonate (ZrHEDP): sodium hydroxyethylidene diphosphonate and ZrOCl 2 ·8H 2 O was dissolved in deionized water to form a solution, and the ZrOCl 2 ·8H 2 The fresh aqueous solution prepared in O was added dropwise to the sodium hydroxyethylidene diphosphonate solution, and the mixture was continuously stirred at room temperature for 8 to 10 hours. The resulting white precipitate was separated by centrifugation and washed with deionized water to remove Na + and Cl - , and then washed with absolute ethanol, repeated washing with water and alcohol twice, and dried at 80°C for 8 to 12 hours to obtain the zirconium hydroxyethylidene diphosphonate catalyst, in which sodium hydroxyethylidene diphosphonate and ZrOCl 2 ·8H 2 The feed molar ratio of O is 1:2.

Embodiment 2

[0029] Preparation of Zirconium Aminotrimethylene Phosphonate (ZrATMP): Sodium Aminotrimethylene Phosphonate and ZrOCl 2 were dissolved in deionized water to form a solution, and the ZrOCl 2 The prepared fresh aqueous solution was added dropwise to the sodium aminotrimethylene phosphonate solution, and the mixture was continuously stirred at room temperature for 8-10 hours. The white precipitate was separated by centrifugation and washed with deionized water to remove Na + and Cl - , and then washed with absolute ethanol, repeated washing with water and alcohol for 3 times, and dried at 80°C for 8 to 12 hours to obtain the zirconium aminotrimethylene phosphonate catalyst, in which sodium aminotrimethylene phosphonate and ZrOCl 2 The feeding molar ratio is 1:3.

Embodiment 3

[0031] The preparation of zirconium ethylenediamine tetramethylene phosphonate (ZrEDTMPs): replace sodium hydroxyethylidene diphosphonate in Example 1 with sodium ethylenediamine tetramethylene phosphonate, wherein ethylenediamine tetramethylene phosphonate Sodium Oxide and ZrOCl 2 ·8H 2 The feeding molar ratio of O is 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com