Carbon fiber enhanced carbon-silicon carbide friction material as well as preparation method and application thereof

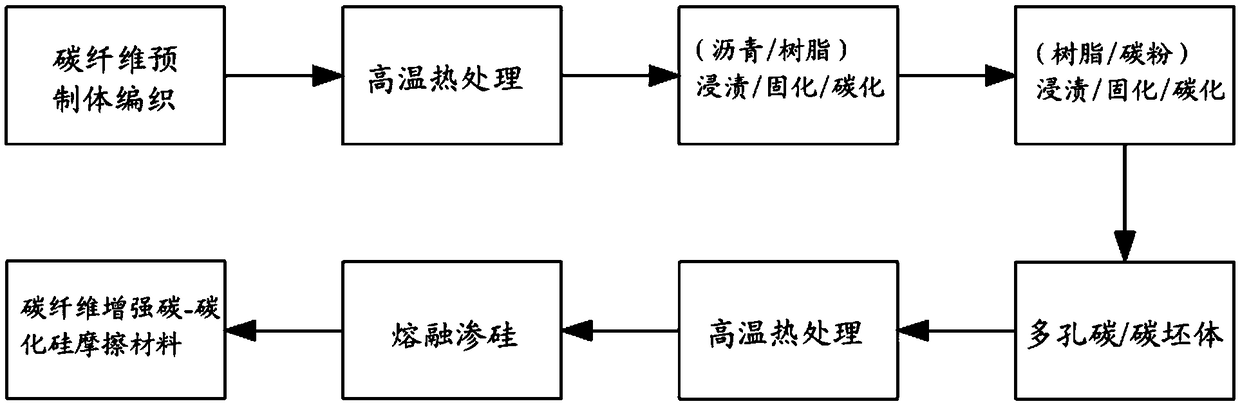

A technology of friction material and carbon fiber prefabricated body, which is applied in the field of carbon fiber reinforced carbon-silicon carbide friction material and its preparation, and can solve the problems of difficult control of porous carbon/carbon body density and porosity, low carbon yield, and long impregnation cycle and other problems, to achieve the effect of enhancing interlayer shear performance, improving friction stability, and improving distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment 1 provides a method for preparing a carbon fiber reinforced carbon-silicon carbide friction material, which includes the following steps:

[0045] (1) Weaving and forming of carbon fiber prefabricated body:

[0046] Using the non-weft cloth and the net tire as the matrix ply structure unit, layer by layer and continuous needle punching to form a carbon fiber prefabricated body with a carbon fiber integral needle felt structure; wherein, the volume density of the obtained carbon fiber prefabricated body is 0.42g / cm 3 , the needling density is 30 needles / cm 2 ; The mass ratio of the weft-free fabric to the mesh tire is 7:3, the weft-free fabric adopts a 0° / 45° / 90° layering method, and the interlayer density of the weft-free fabric is 12 layers / cm;

[0047] (2) High temperature heat treatment of carbon fiber preform:

[0048] Load the carbon fiber prefabricated body produced in step (1) into a high-temperature furnace, and perform a high-temperature heat ...

Embodiment 2

[0062] This embodiment 2 provides a method for preparing a carbon fiber reinforced carbon-silicon carbide friction material, which includes the following steps:

[0063] (1) Weaving and forming of carbon fiber prefabricated body:

[0064] Using the non-weft cloth and the mesh tire as the matrix ply structure unit, layer by layer and continuous needle punching to form a carbon fiber prefabricated body with a carbon fiber integral needle felt structure; wherein, the volume density of the obtained carbon fiber prefabricated body is 0.52g / cm 3 , the needling density is 40 needles / cm 2 ; The mass ratio of the weft-free fabric to the mesh tire is 4:1, the weft-free fabric adopts a 0° / 45° / 90° layering method, and the interlayer density of the weft-free fabric is 15 layers / cm;

[0065] (2) High temperature heat treatment of carbon fiber preform:

[0066] Load the carbon fiber prefabricated body produced in step (1) into a high-temperature furnace, and perform a high-temperature heat...

Embodiment 3

[0080] This embodiment 3 provides a method for preparing a carbon fiber reinforced carbon-silicon carbide friction material, which includes the following steps:

[0081] (1) Weaving and forming of carbon fiber prefabricated body:

[0082] Using the non-weft cloth and the mesh tire as the matrix ply structure unit, layer by layer and continuous needle punching to form a carbon fiber prefabricated body with a carbon fiber integral needle felt structure; wherein, the volume density of the obtained carbon fiber prefabricated body is 0.45g / cm 3 , the needling density is 40 needles / cm 2 ; The mass ratio of the weft-free fabric to the mesh tire is 3:1, the weft-free fabric adopts a 0° / 45° / 90° layering method, and the interlayer density of the weft-free fabric is 14 layers / cm;

[0083] (2) High temperature heat treatment of carbon fiber preform:

[0084] Load the carbon fiber prefabricated body produced in step (1) into a high-temperature furnace, and perform a high-temperature heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Needling density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com