A method for intensified grinding of gear-tooth-shaped workpieces

A technology for grinding and processing workpieces, which is applied in the field of grinding and processing gear-shaped workpieces, and can solve the problems of easily damaged gear-shaped workpiece working surface design radian, easy drop of mixed material into supporting table for processing, and easy oxidation of workpiece processing surface, etc. To achieve the effect of convenient clamping and disassembly, realize cyclic periodic processing, and improve roundness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

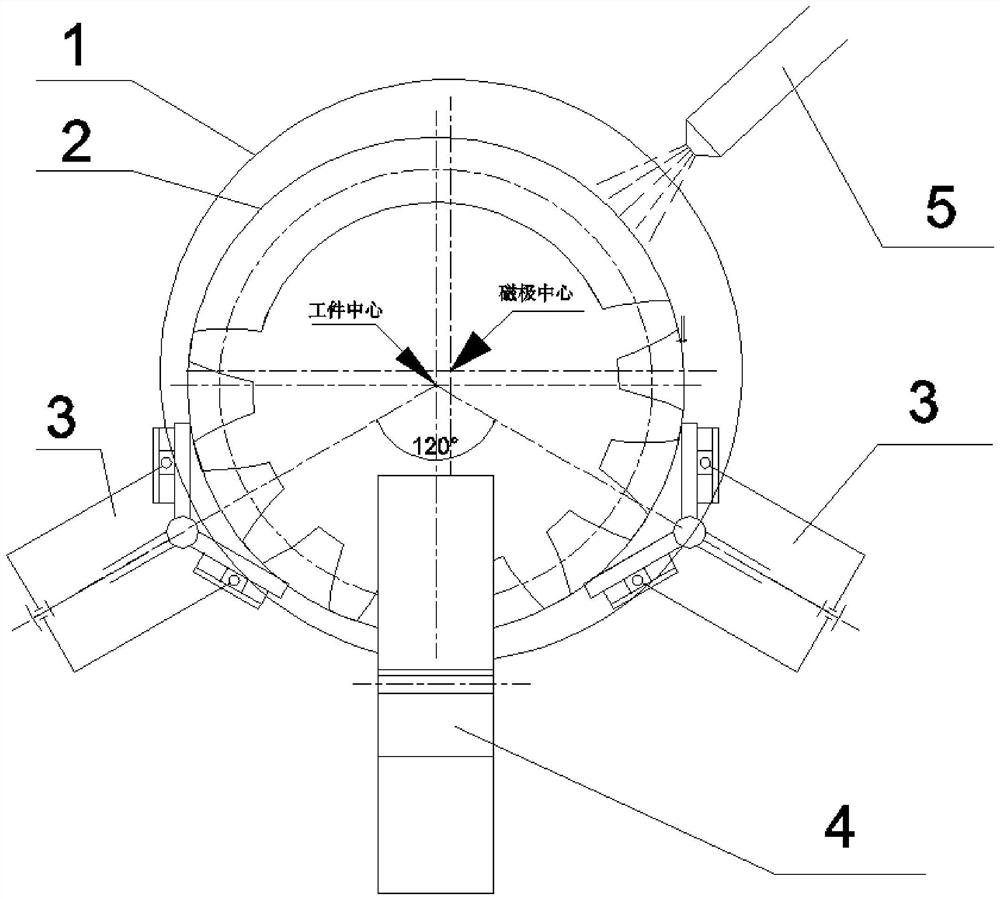

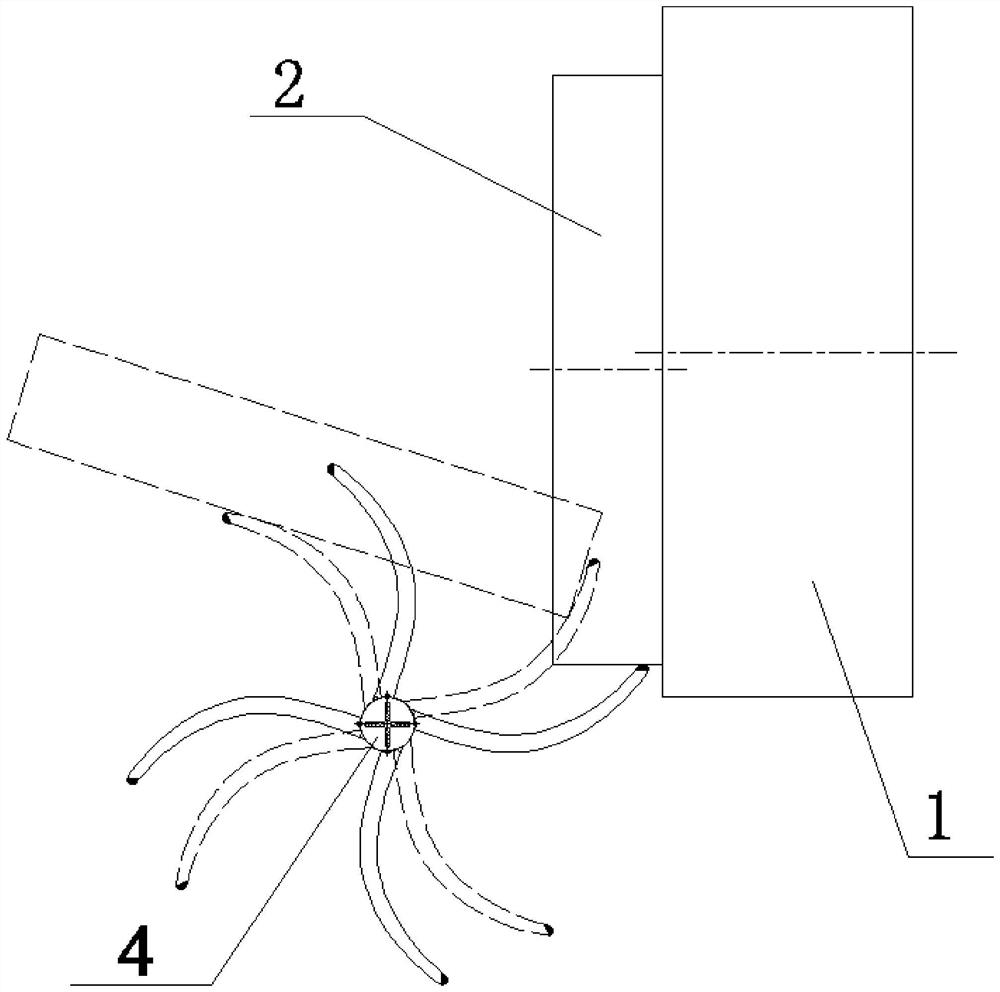

[0035] combine Figure 6 As shown, a method for intensified grinding of a gear-tooth-shaped workpiece comprises the following steps:

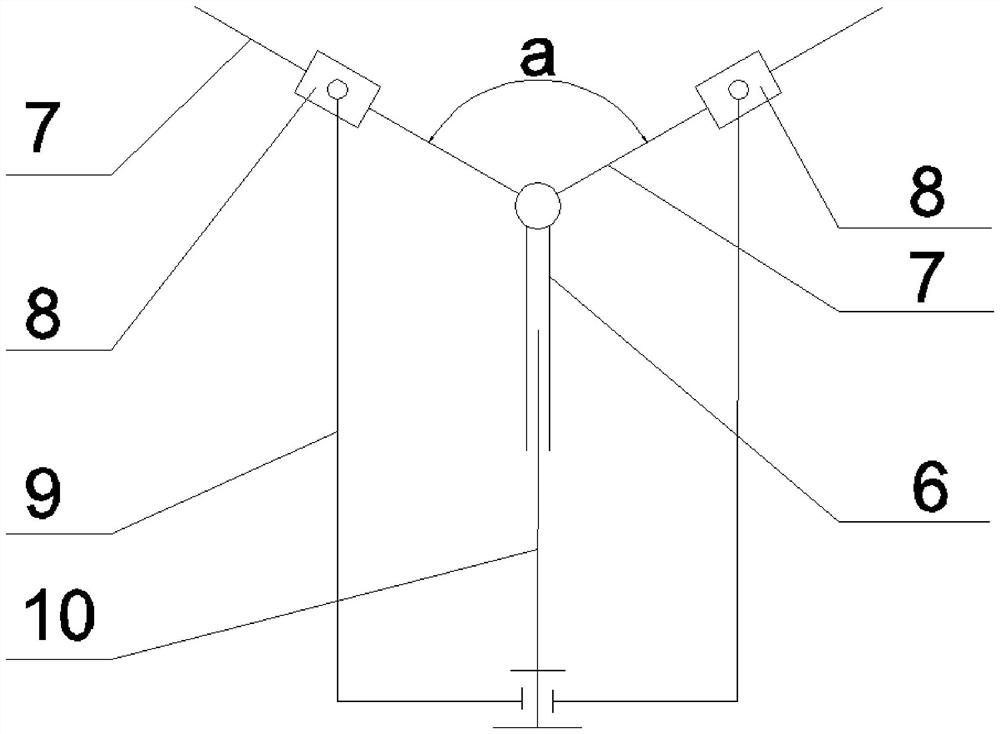

[0036] Step 1: Place the gear-tooth-shaped workpiece on the support table of the electromagnetic centerless fixture, adjust the first V-shaped block so that the angle between the center line of the first V-shaped block and the horizontal plane is A, and make the first V-shaped block The vertical distance between the highest point of the V-shaped block and the center vertical line of the tooth-shaped workpiece is less than the radius R of the tooth-shaped workpiece, that is, the distance L from the upper right corner of the right V-shaped block to the vertical center line of the tooth-shaped workpiece <Radius R of the tooth-shaped workpiece. The range of angle A is -15°<A<-45°.

[0037] combine Figure 6 As shown, the V-shaped block is a symmetrical structure, and the centerline of the V-shaped block is the symmetrical centerline of the V-sha...

Embodiment 2

[0062] Except for the following technical features, all the other unsubmitted technical features are the same as in Embodiment 1.

[0063] The difference between this embodiment and embodiment 1 is that the numerical values of the specific processing examples are different.

[0064] Such as Figure 6 As shown, the tooth-shaped workpiece to be processed is a helical gear or a herringbone gear.

[0065] A method for intensified grinding processing of a gear-tooth-shaped workpiece, the specific processing steps are:

[0066] Step 1: Place the tooth-shaped workpiece on the support table of the electromagnetic centerless fixture, adjust the first V-shaped block so that the angle A between the center line of the first V-shaped block and the horizontal plane is 35°, and make the second V-shaped block The vertical distance between the highest point of a V-shaped block and the center vertical line of the tooth-shaped workpiece is less than the radius R of the tooth-shaped workpiece...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com