A high temperature superconducting magnet winding method

A winding method and high-temperature superconducting technology, which is applied in the manufacture of superconducting magnets/coils, magnetic objects, inductors/transformers/magnets, etc., and can solve problems such as difficult processing, winding tool design, and lateral bending of strips , to achieve the effect of simple and convenient winding process, small performance degradation and simple design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

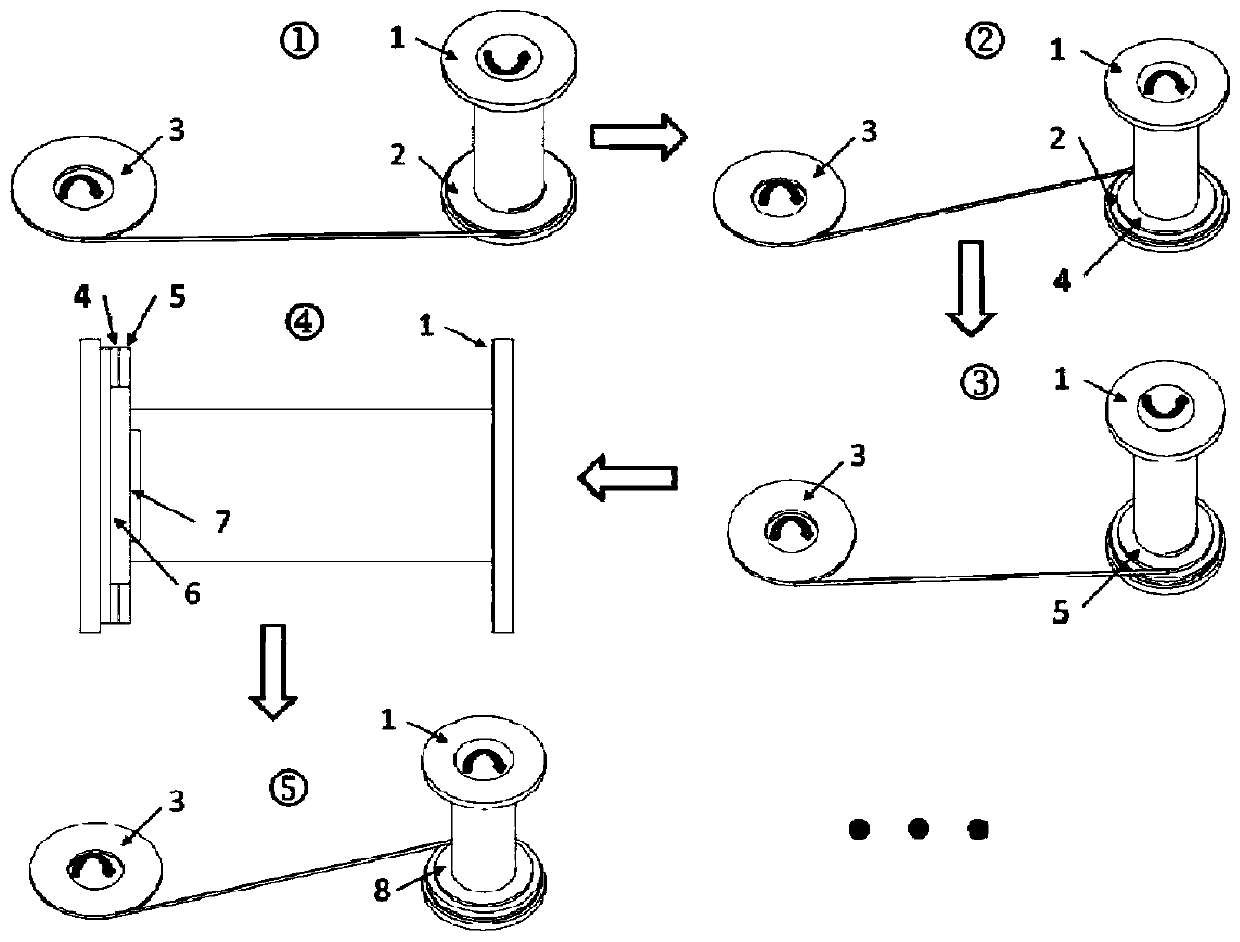

[0029] See attached picture.

[0030] A winding method for a high-temperature superconducting magnet, characterized in that: a skeleton 1 is used for magnet winding, and the continuous winding of odd and even single-cake coils is realized through forward and reverse rotation of the skeleton 1, and adjacent single-cake coils pass through inner joints 7 or external connector 6 to realize electrical connection;

[0031] It specifically includes the following steps:

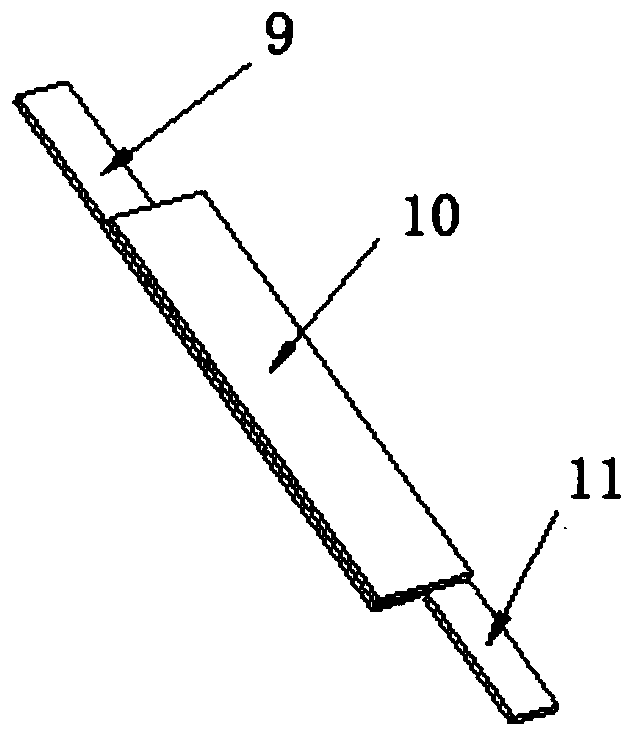

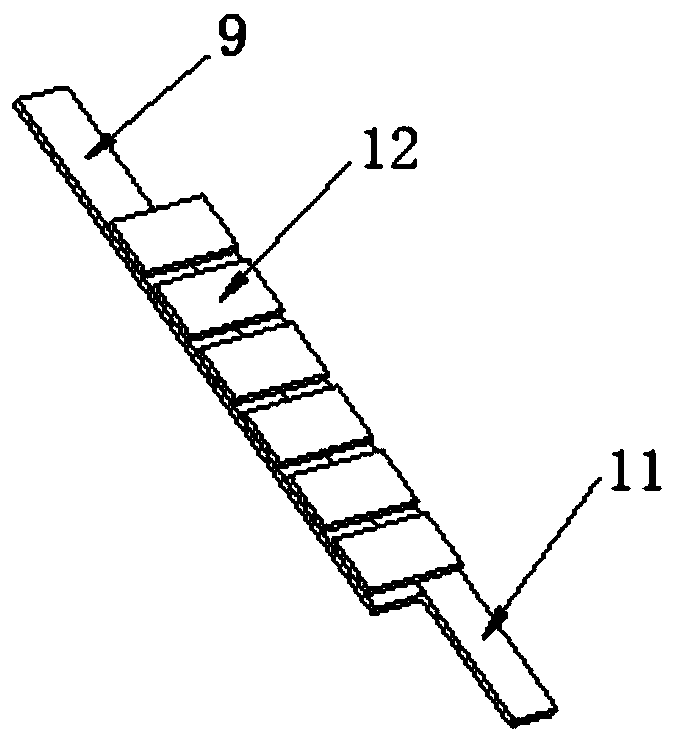

[0032] 1) The outer surface of skeleton 1 is cleaned with alcohol and wrapped with 0.2mm polyimide film for insulation; 2) Connect the inner wire head of the first single cake coil 2, and fix the inner wire head from the outer side of skeleton 1 to skeleton 1, Wind the first single-cake coil 2 to the designed number of layers, and the skeleton 1 rotates counterclockwise; 3) The inner thread head of the second single-cake coil 4 enters the skeleton 1 from the inner side of the skeleton 1 and makes a joint, so that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com