Multi-slagging-hole large-sized-drill-bit-included combination type drilling tool system

A technology of large drill bit and slag discharge port, which is applied in the direction of underwater drilling, earthwork drilling, wellbore/well components, etc. It can solve the problems of reducing mud circulation flow, affecting the effect of slurry discharge and slag discharge, and shortening tool life. Improve the effect of pulp return and slag discharge, simple and convenient independent air source, and reduce the effect of invalid wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

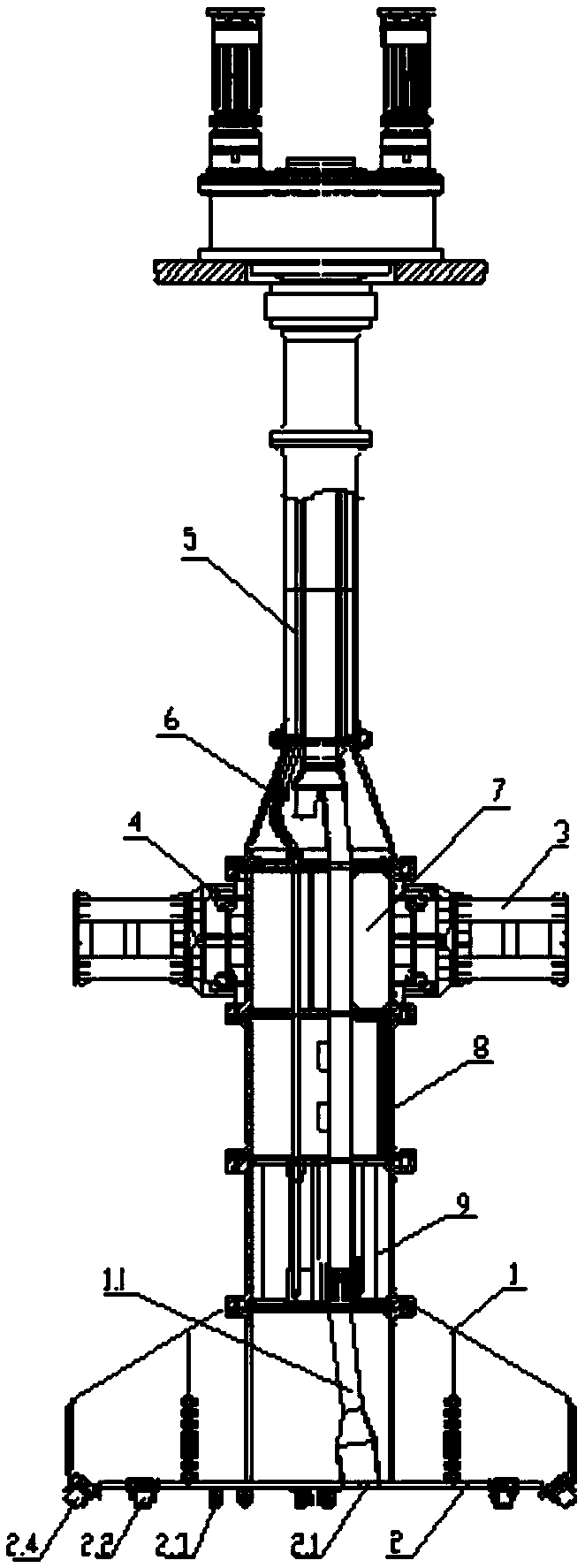

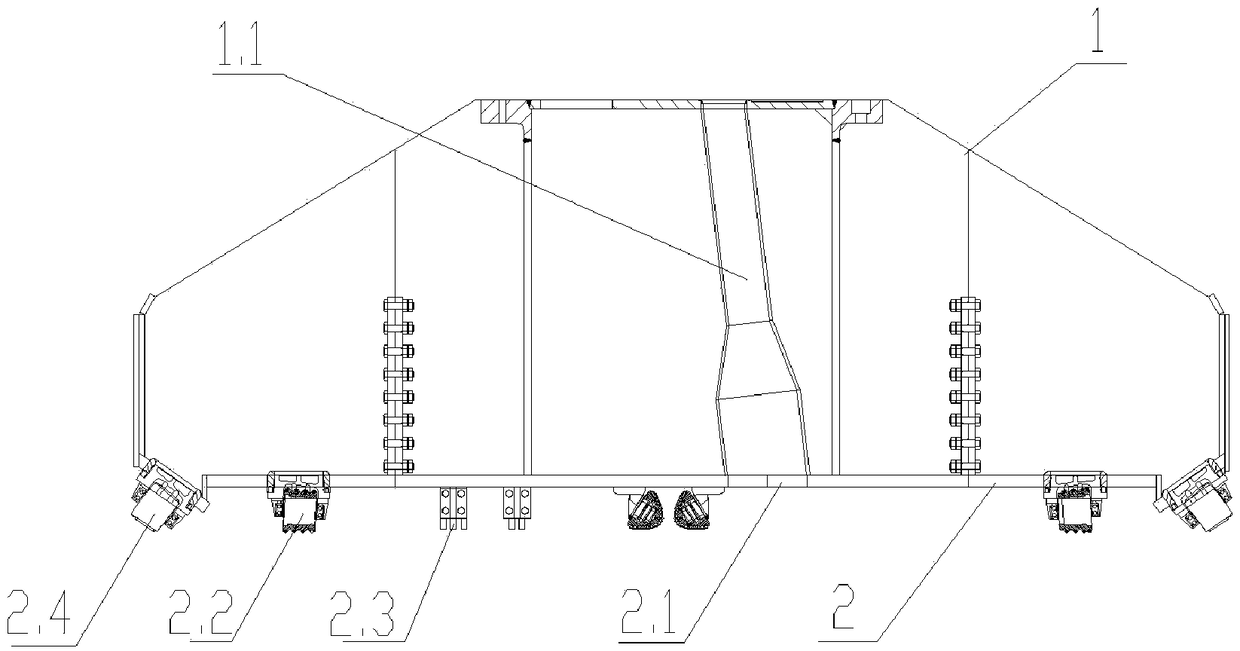

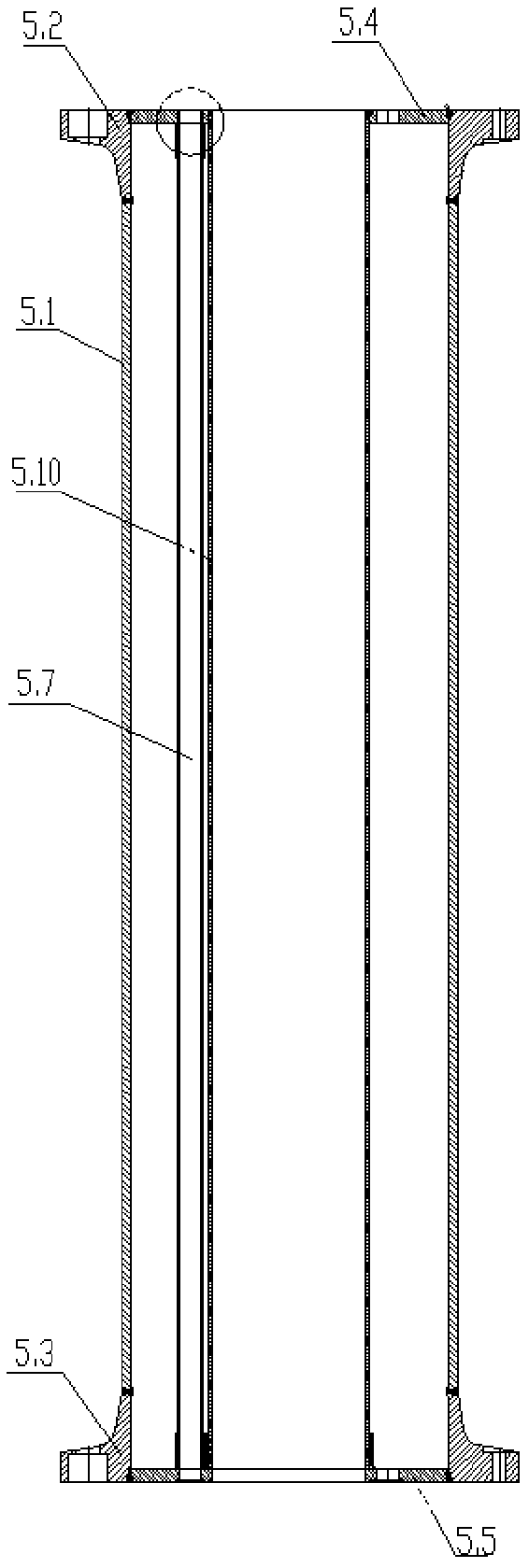

[0032] see Figure 1-9 , the present invention relates to a combined drilling tool system for a large drill bit with multiple slag outlets, comprising a drill bit support 1, the bottom surface of the drill bit support 1 is a cutter head 2, and a plurality of cutters are installed on the cutter head 2; The cutterhead 2 is provided with a plurality of slag outlets 2.1 of oblong structure, and the slag outlets 2.1 of oblong structure are staggered along the radial direction of the cutterhead 2, and the plurality of slag outlets 2.1 follow the cutter head 2 Sweep the entire working surface directly below the cutter head 2 when rotating; multiple slag discharge pipes 1.1 are arranged inside the drill bit support 1, and the bottom section of the slag discharge pipe 1.1 is an oblong structure, and the slag discharge pipes The bottom of one 1.1 is in communication with the slag outlet 2.1 of oblong structure, the cross section of slag discharge pipe 1.1 gradually changes from the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com