Vertical compound tunneling technology

A composite, vertical technology, applied in drill pipe, casing, underwater drilling, etc., can solve problems such as affecting construction progress, reducing construction efficiency, shortening, etc., to improve installation accuracy and efficiency, improve operation efficiency, extend the The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

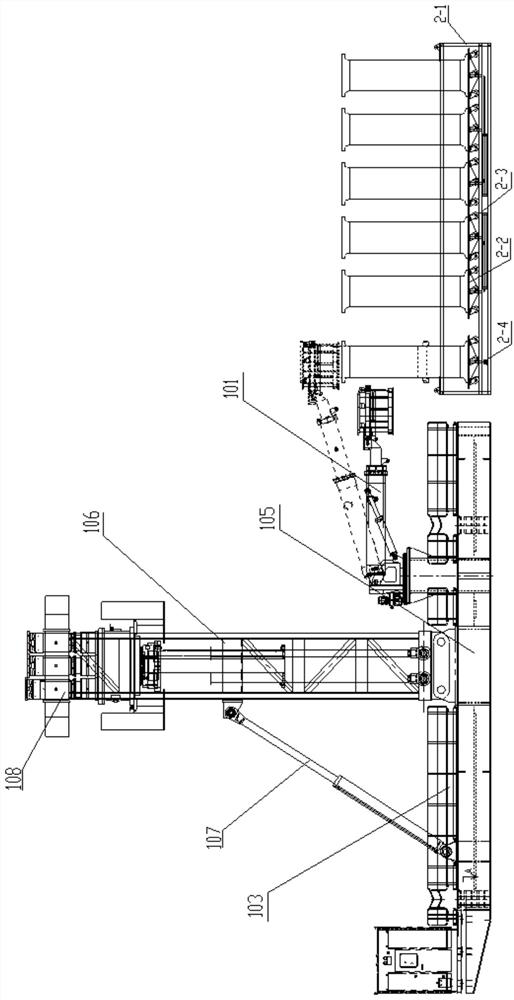

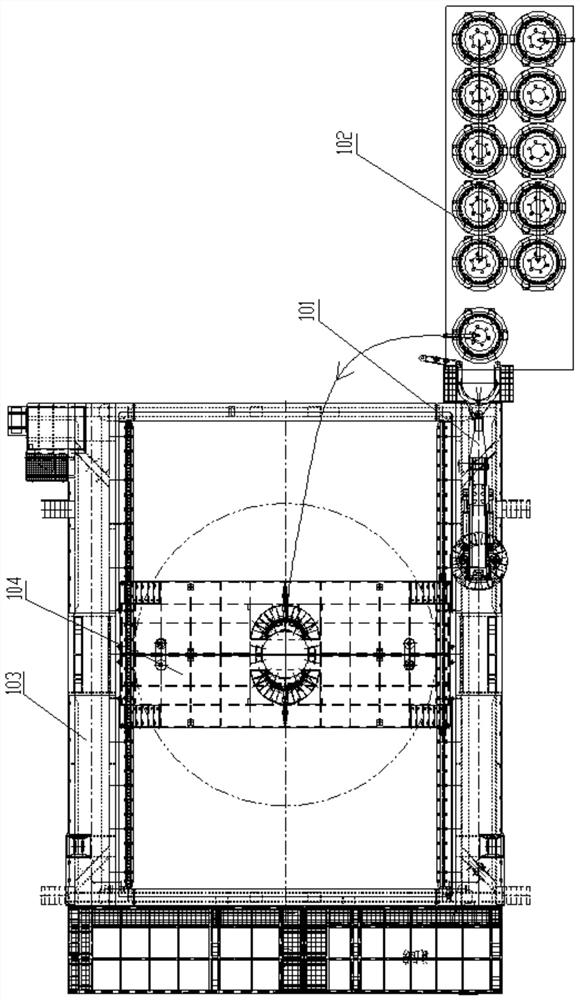

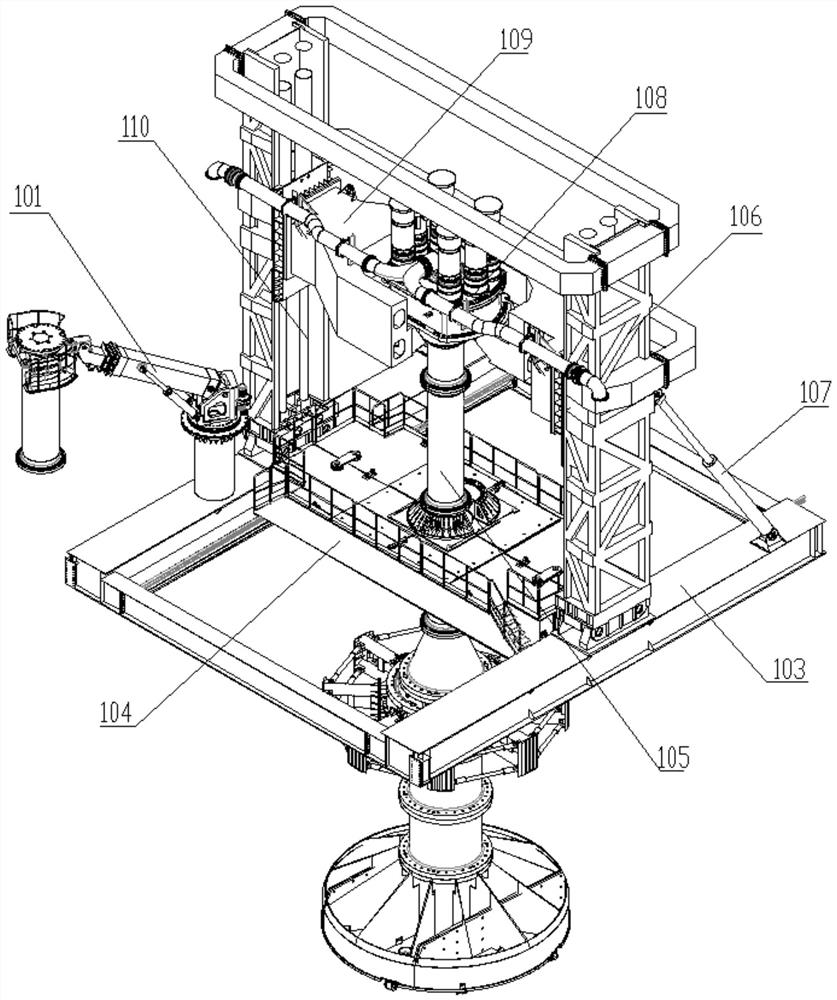

[0087] see Figure 1-34 , the present invention relates to a vertical compound excavation process, the system includes a drilling rig chassis 103, the manipulator 101 is installed on the drilling rig chassis 103, the drill rod moving device 102 is located on the drilling rig chassis 103, two sealing platforms 104 is slidably arranged on the chassis 103 of the drilling rig, and the drill pipe assembly 105 is clamped vertically between the two sealing platforms 104, the gantry 106 is installed on the chassis 103 of the rig, and the inner side of the vertical bar of the gantry 106 is vertically provided with guide rails, The left and right ends of the horizontally arranged lifting platform 109 slide respectively in the guide rails on both sides of the gantry frame 106, the piston rod of the vertically arranged hydraulic cylinder 110 is connected with the lifting platform 109, and the power head 108 installed on the lifting platform 109 drives drill pipe assembly 105;

[0088] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com