Slidable spacer for exhaust pipe

A sliding gasket, exhaust pipe technology, applied in the direction of exhaust devices, engine components, machines/engines, etc., can solve problems such as cracking and leakage of exhaust pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

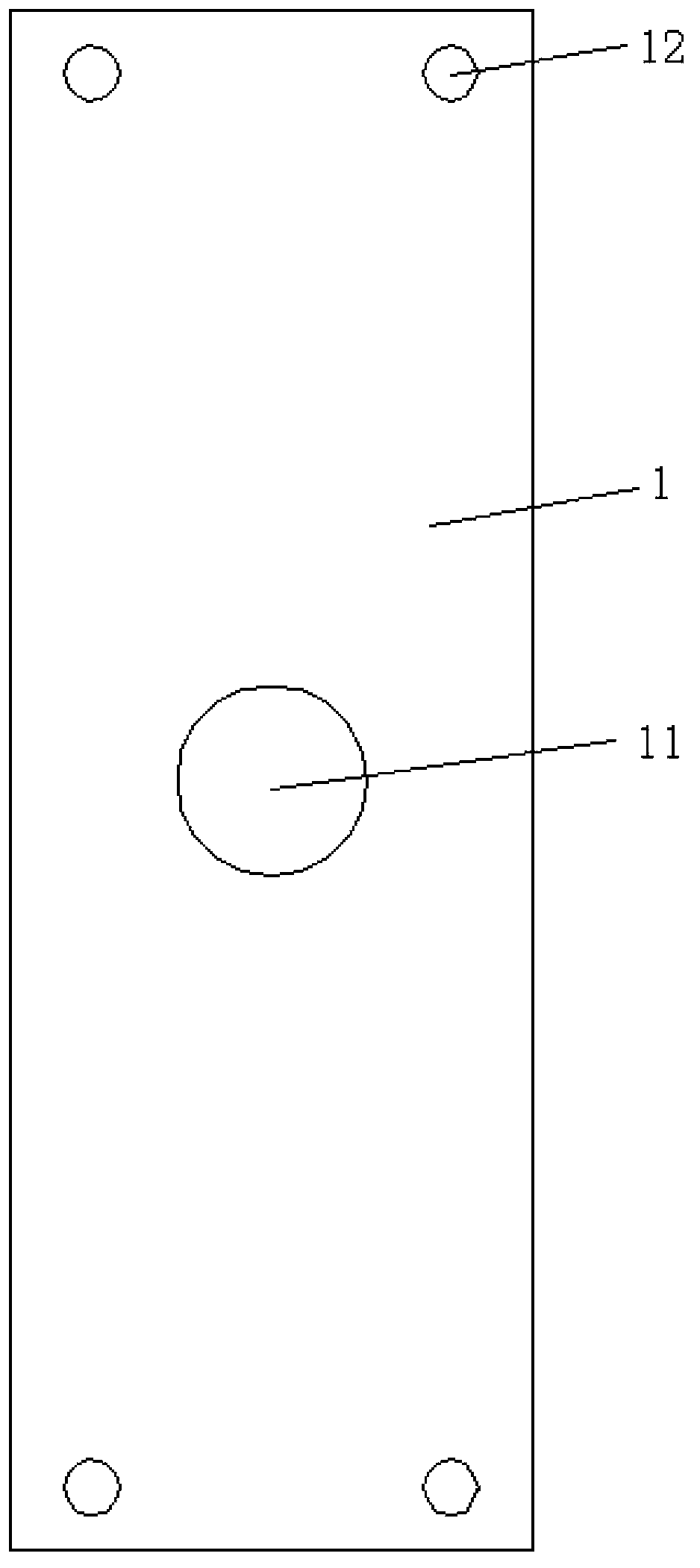

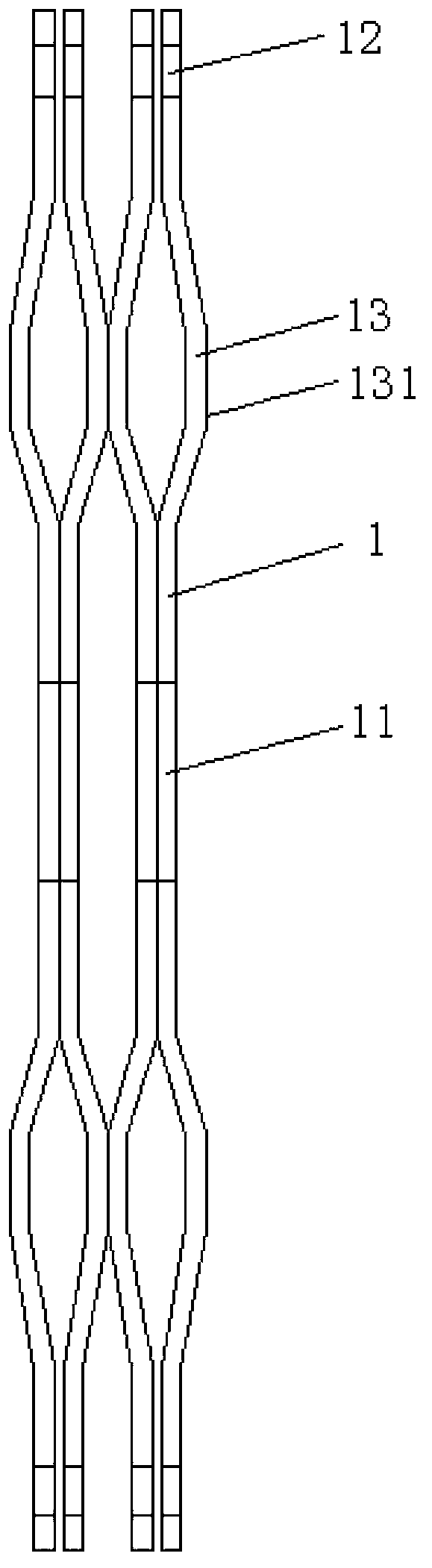

[0012] Embodiment: The present invention includes a gasket body 1 provided with vent holes 11 and screw holes 12, including four gasket bodies 1, and between the vent holes 11 and screw holes 12 of each gasket body 1 is a The protruding convex structure 13, the two ends between the two gasket bodies 1 are provided with a gap, the convex structure 13 is provided with an installation platform 131, and the surface of the gasket body 1 can also be provided with disulfide Molybdenum coating.

[0013] When in use, the present invention is arranged between two exhaust pipes. When the exhaust pipes are thermally expanded and deformed, the gasket body 1 is squeezed and slides toward the middle to compress and slide, thereby absorbing the thermal deformation of the exhaust pipes and preventing the exhaust pipes from cracking Air leak.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com