An offshore drilling technique

A process and drill pipe technology, applied in the field of marine construction equipment, can solve the problems of inconsistent resistance of the absorption port, poor torsion resistance, and different absorption capacity, etc., to improve the effect of slurry returning and slag discharge, uniform pressure distribution, and prevent cracking and leakage. gas effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

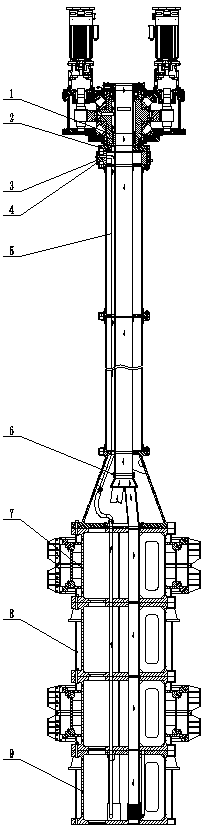

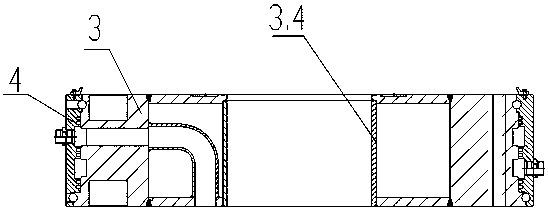

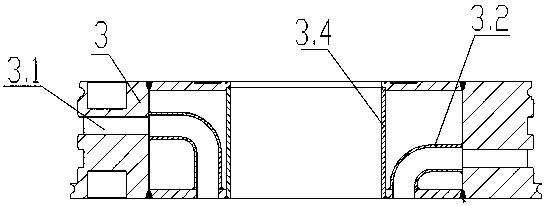

[0040] see Figure 1~10 , an offshore drilling process related to the present invention, the high-pressure gas is vertically introduced into the bottom of the drill pipe through a plurality of air pipes, and each air pipe is respectively connected with a vertically arranged slag discharge branch pipe, and is passed into the slag discharge branch pipe. The high-pressure gas in the branch pipe is mixed with the mud in the pipe and then discharged upwards, and multiple slag discharge branch pipes are collected into the same slag discharge pipe inside the drill pipe and then discharged upward;

[0041] The process is realized based on a drilling tool system. The system includes an air distribution device driven by a power head 1. The air distribution device is composed of an air distribution shaft 3, an air distribution sleeve 4, a bearing and a sealing ring. The sleeve 4 is set outside the air distribution shaft 3 through bearings, and a plurality of drill pipes 5 are vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com