Preparation method of green wallpaper adhesive

An adhesive and wallpaper technology, which is applied in the field of preparation of green wallpaper adhesives, can solve problems such as poor peeling strength, and achieve the effects of reducing stringiness, reducing costs, and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

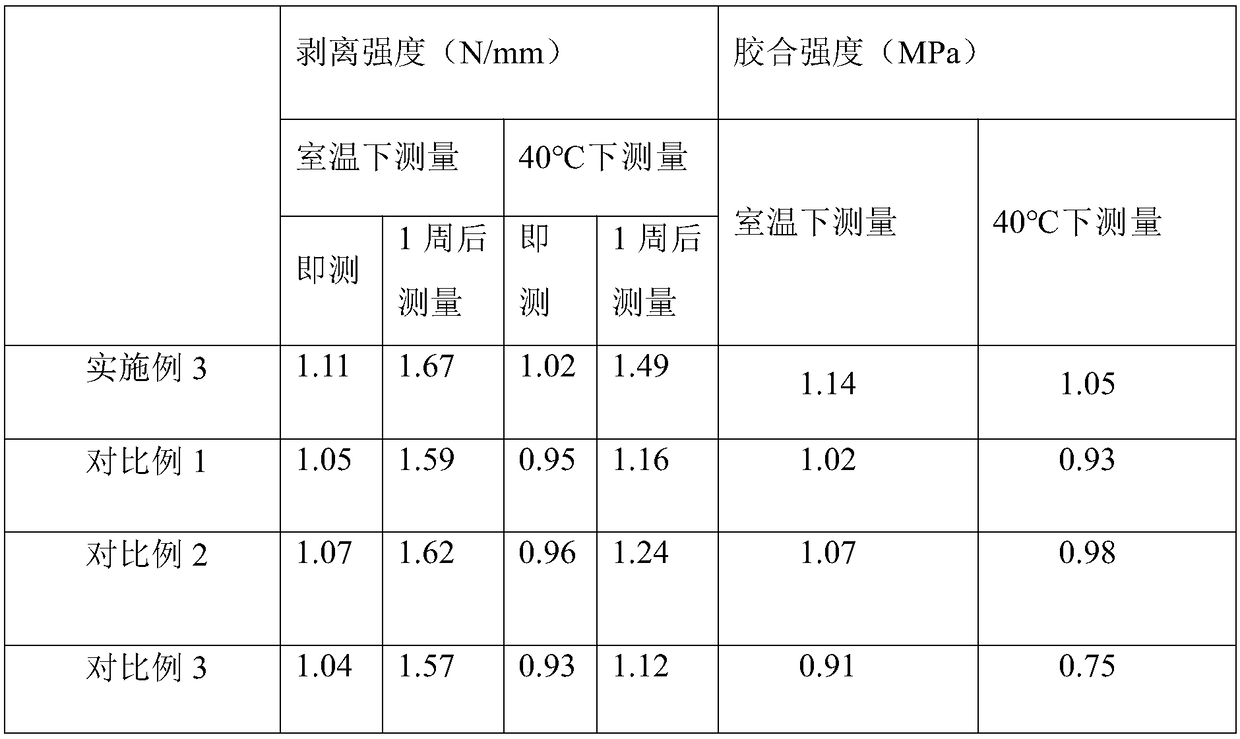

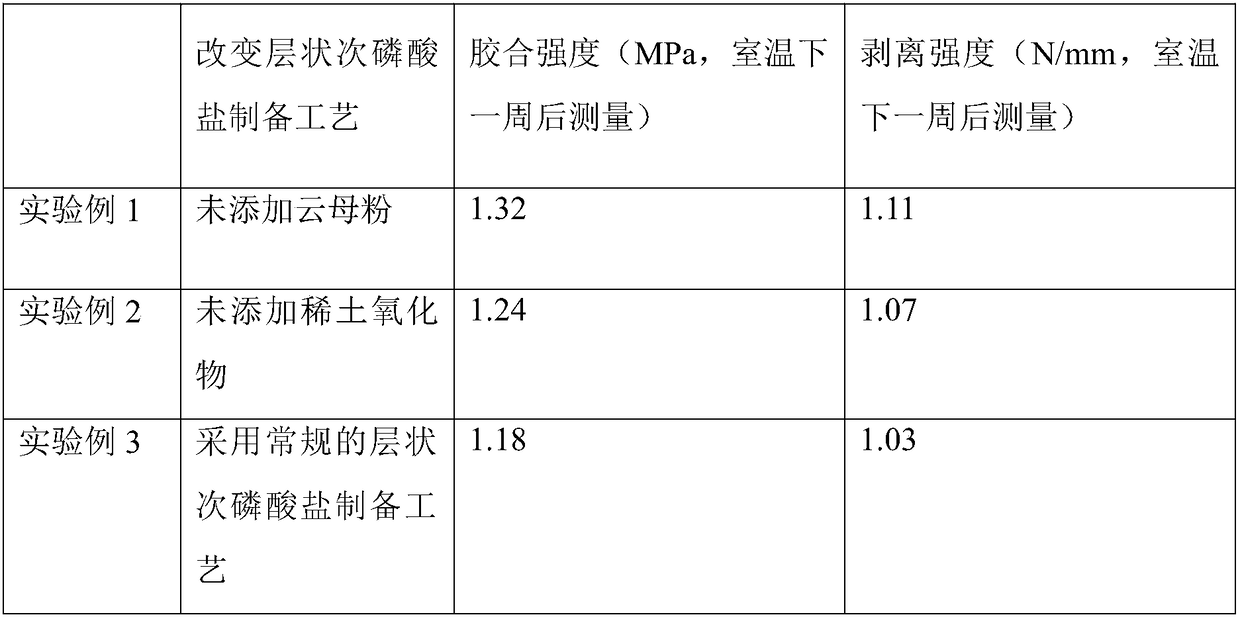

Examples

Embodiment 1

[0026] A kind of preparation method of green wallpaper adhesive of the present embodiment comprises the following steps:

[0027] Step 1, according to the parts by weight, weigh 44 parts of modified graphene and add it to the reaction kettle, adjust the temperature to 55 ° C, react for 15 minutes, then add 62 parts of 40% hydrochloric acid solution by mass fraction to it, and prepare modified graphite Then add 12 parts of hydroxypropyl starch and 16 parts of ethanol solution to it, stir for 15 minutes, then add 8 parts of layered hypophosphite, and carry out ultrasonic dispersion for 15 minutes to obtain premix A;

[0028] Step 2, adding casein to 6 times its weight in deionized water, stirring evenly, ultrasonically dispersing for 3 minutes, then adding an organic alcohol amine compound accounting for 2% of the mass of the mixed solution to adjust the pH value to 7-8, and stirring for 30 minutes to obtain casein plain solution; then mix the casein solution and epoxy resin in ...

Embodiment 2

[0041] A kind of preparation method of green wallpaper adhesive of the present embodiment comprises the following steps:

[0042] Step 1, according to the parts by weight, weigh 48 parts of modified graphene and add it to the reaction kettle, adjust the temperature to 65 ° C, react for 25 minutes, then add 68 parts of 50% hydrochloric acid solution by mass fraction to it, and prepare modified graphite Then add 16 parts of hydroxypropyl starch and 22 parts of ethanol solution to it, stir for 25 minutes, then add 14 parts of layered hypophosphite, and carry out ultrasonic dispersion for 25 minutes to obtain premix A;

[0043] Step 2: Add casein to 8 times its weight in deionized water, stir evenly, disperse by ultrasonic for 5 minutes, then add an organic alcohol amine compound accounting for 4% of the mass of the mixed solution to adjust the pH value to 7-8, and stir for 45 minutes to obtain casein Plain solution; then mix the casein solution and epoxy resin according to the we...

Embodiment 3

[0056] A kind of preparation method of green wallpaper adhesive of the present embodiment comprises the following steps:

[0057] Step 1, according to the parts by weight, weigh 46 parts of modified graphene and add it to the reactor, adjust the temperature to 60 ° C, react for 20 minutes, then add 65 parts of 45% hydrochloric acid solution by mass fraction to it, and prepare modified graphite Then add 14 parts of hydroxypropyl starch and 19 parts of ethanol solution to it, stir for 20 minutes, then add 11 parts of layered hypophosphite, and carry out ultrasonic dispersion for 20 minutes to obtain premix A;

[0058] Step 2: Add casein to 7 times its weight in deionized water, stir evenly, disperse by ultrasonic for 4 minutes, then add 3% organic alcohol amine compound accounting for the mass of the mixed liquid to adjust the pH value to 7-8, and stir for 37 minutes to obtain casein Vegetable solution; then mix the casein solution and epoxy resin according to the weight ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com