Surface coating slurry of platinum heating wire as well as preparation method and coating device of surface coating slurry

A technology of surface coating and coating device, applied in alkali metal silicate coatings, coatings, anti-corrosion coatings, etc. Good strength and impermeability, not easy to fall off, and improve the effect of weathering resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

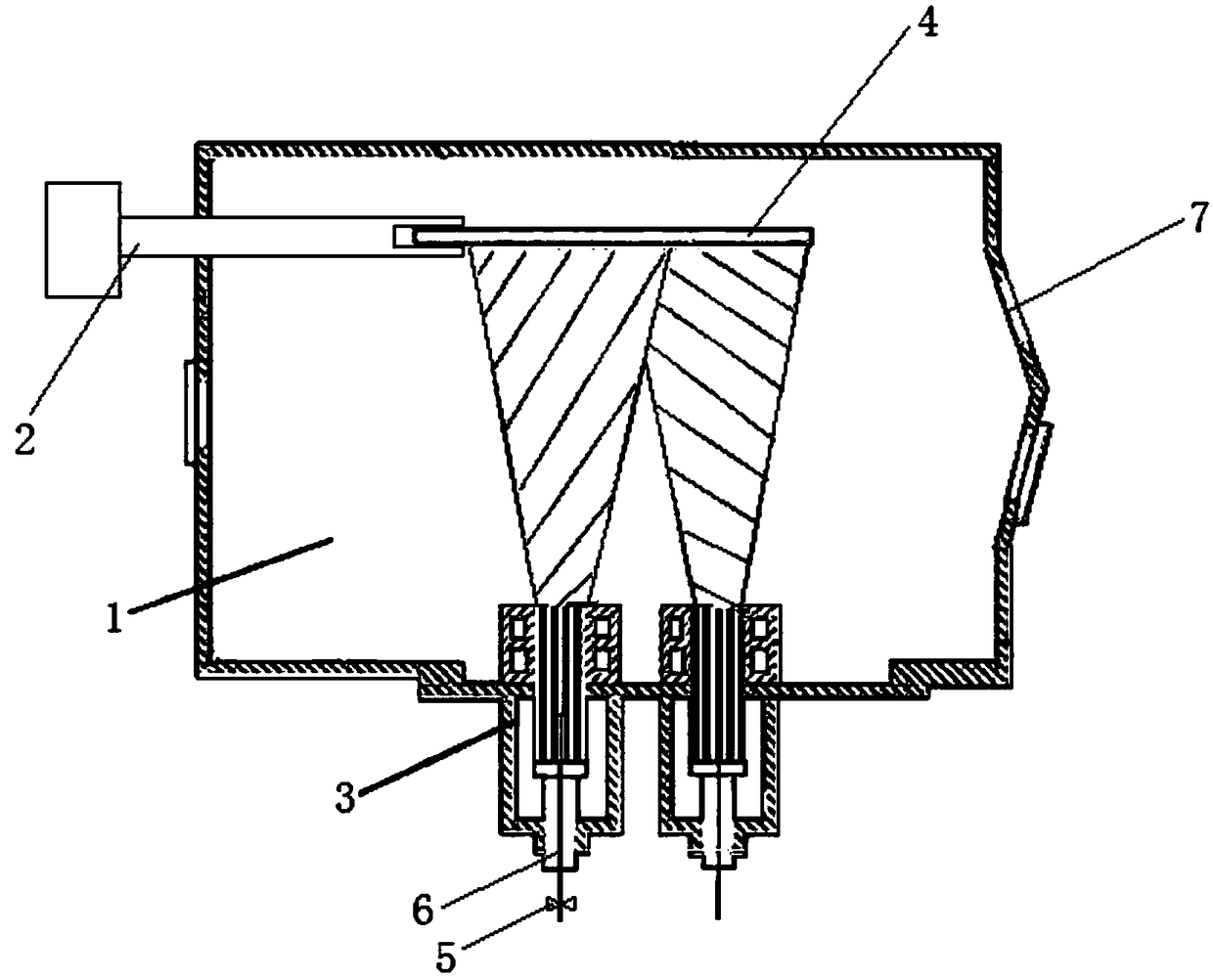

Image

Examples

Embodiment 1

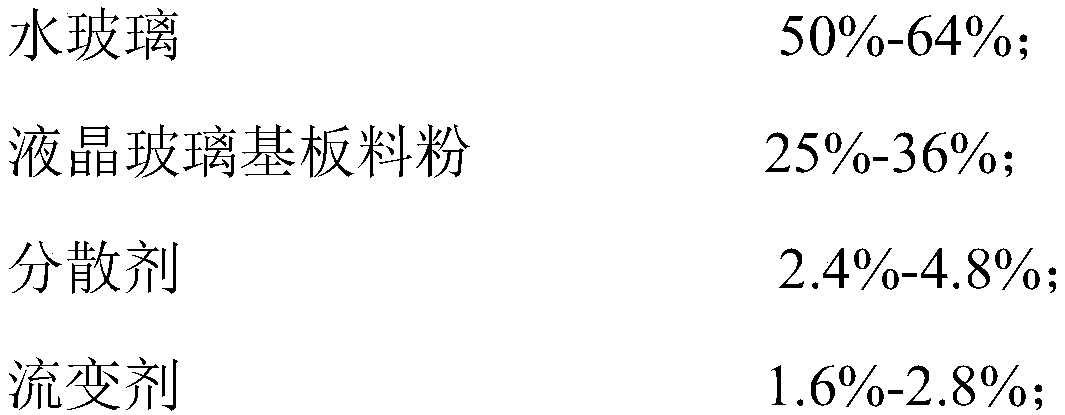

[0032] The surface coating slurry of platinum heating wire contains 55% water glass, 36% liquid crystal glass substrate material powder, 2.4% polyacrylic acid ammonium, 1.6% carboxymethyl cellulose and 5% Sodium fluorosilicate; Among them, the liquid crystal glass substrate powder contains 66% SiO 2 , 16% Al 2 o 3 , 4% B 2 o 3 , 4% MgO, 7.8% CaO, 2% SrO and 0.2% BaO; the water glass is selected from GB / T 4209 2008 liquid-2 superior product.

[0033] Prepare as follows:

[0034] Step 1. First use absolute ethanol as the medium to wet mix the liquid crystal glass substrate powder for 3 hours, then put it in a drying oven at 200°C for 4 hours, add the dried liquid crystal glass substrate powder to the water glass, and then add Ammonium polyacrylate, carboxymethyl cellulose and sodium fluorosilicate are mixed evenly, ammonia water is added, and the pH value is adjusted to 10 to obtain a suspension slurry;

[0035] Step 2, putting the non-agglomerated suspension slurry prepar...

Embodiment 2

[0037] The surface coating slurry of platinum heating wire contains 50% water glass, 33% TFT-LCD liquid crystal glass substrate material powder, 4.8% polyacrylic acid ammonium, 2.2% carboxymethyl cellulose and 10% sodium fluorosilicate; Among them, TFT-LCD liquid crystal glass substrate powder contains 65% SiO 2 , 15% Al 2 o 3 , 3.8% B 2 o 3 , 4% of MgO, 9.5% of CaO, 2.2% of SrO and 0.5% of BaO; water glass is selected from GB / T 4209 2008 liquid-2 superior product.

[0038] Prepare as follows:

[0039] Step 1. First use absolute ethanol as the medium, wet mix the TFT-LCD liquid crystal glass substrate powder for 3 hours, put it in a drying oven at 180°C for 5 hours, add the dried TFT-LCD liquid crystal glass substrate powder to water Add ammonium polyacrylate, carboxymethyl cellulose and sodium fluorosilicate to the glass, mix well, add ammonia water, adjust the pH value to 10, and obtain a suspension slurry;

[0040] Step 2, putting the non-agglomerated suspension slurr...

Embodiment 3

[0042] The surface coating slurry of platinum heating wire contains 60% water glass, 30% liquid crystal glass substrate material powder, 3% polyacrylic acid ammonia, 2% carboxymethyl cellulose and 5% Sodium fluorosilicate; wherein, liquid crystal glass substrate powder contains 62% SiO 2 , 16% Al 2 o 3 , 4.5% B 2 o 3 , 5% MgO, 9.5% CaO, 2.5% SrO and 0.5% BaO; the water glass is selected from GB / T 4209 2008 liquid-2 superior product.

[0043] Prepare as follows:

[0044] Step 1. First use absolute ethanol as the medium, wet-mix the liquid crystal glass substrate powder for 5 hours, then put it in a drying oven at 210°C for 3 hours, add the dried liquid crystal glass substrate powder to the water glass, and then add Ammonium polyacrylate, carboxymethyl cellulose and sodium fluorosilicate are mixed evenly, ammonia water is added, and the pH value is adjusted to 10 to obtain a suspension slurry;

[0045] Step 2, putting the non-agglomerated suspension slurry prepared in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com