Cathode of lithium ion battery, all-solid-state lithium ion battery, preparation method and electric device thereof

A lithium-ion battery, all-solid-state technology, applied in the direction of electrode carrier/current collector, electrode manufacturing, battery electrode, etc., can solve the problems of difficult and difficult to realize microcircuit integration, detachment, etc., and achieve the effect of low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

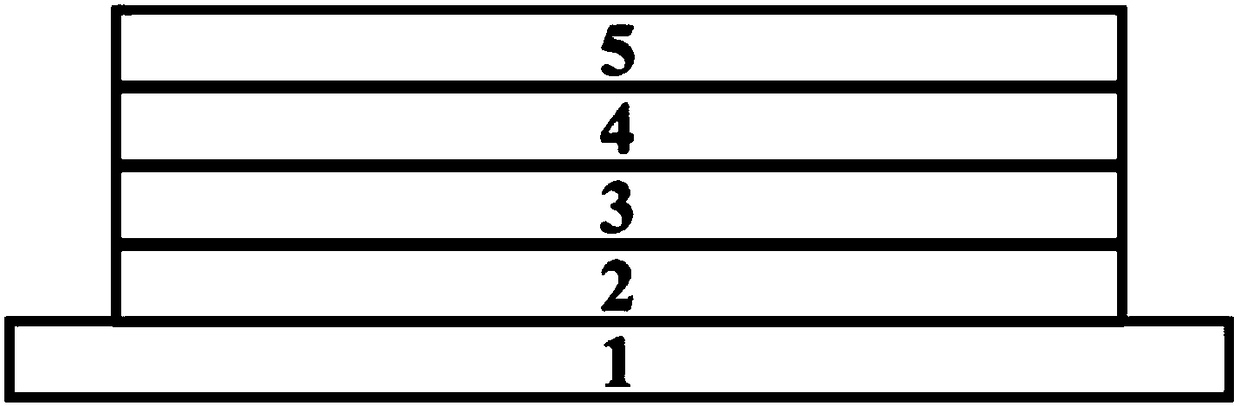

[0054] This embodiment is an all-solid-state thin-film lithium-ion battery, and its structure is as follows: figure 1 Shown, its preparation method comprises the following steps:

[0055] S1) The DC magnetron sputtering method is adopted, a pure Mn metal target is used as the target material, and stainless steel is used as the positive current collector 1 . After installing the target and positive current collector, close the sputtering chamber and evacuate the sputtering chamber to 1.0×10 -4 Below Pa, feed 100sccm argon and 20sccm oxygen, and then adjust the gas pressure in the chamber to 1Pa; set the DC sputtering power to 1.4W / cm 2 , the base distance of the target is 80 mm, pre-sputtering for 5 minutes to clean the impurities on the target surface, and sputtering for 3 hours at room temperature can directly obtain the manganese tetraoxide thin film 2 on the substrate;

[0056] S2) In the obtained Mn 3 o 4 On the basis of the thin film, the LiPON solid electrolyte thin ...

Embodiment 2

[0063] This embodiment is an all-solid-state thin-film lithium-ion battery, and its preparation method comprises the following steps:

[0064] S1) The DC magnetron sputtering method is adopted, a pure Mn metal target is used as the target material, and a platinum-coated glass sheet is used as the positive current collector. After installing the target and positive current collector, close the sputtering chamber and evacuate the sputtering chamber to 1.0×10 -4 Below Pa, feed 100sccm argon and 20sccm oxygen, and then adjust the gas pressure in the chamber to 1Pa; set the DC sputtering power to 1.4W / cm 2 , target base distance 80mm, pre-sputtering for 5 minutes to clean the impurities on the surface of the target, heating the substrate to 400°C and sputtering for 3 hours, the trimanganese tetraoxide thin film can be obtained directly on the substrate;

[0065] S2) In the obtained Mn 3 o 4 On the basis of the thin film, the LiPON solid electrolyte thin film is prepared by magne...

Embodiment 3

[0071] This embodiment is an all-solid-state thin-film lithium-ion battery, and its preparation method comprises the following steps:

[0072] S1) Use gold-plated stainless steel foil as the working electrode, platinum sheet as the counter electrode, Ag / AgCl as the reference electrode, and a mixed solution of 0.1M manganese acetate and 0.1M sodium sulfate as the electrolyte. Deposited for 15min, Mn was prepared directly on gold-plated stainless steel foil 3 o 4 film;

[0073] S2) in Mn 3 o 4 On the basis of the thin film, the LiPON solid electrolyte thin film is prepared by magnetron sputtering;

[0074] S3) On the basis of the solid electrolyte film, thermal evaporation equipment is used to vapor-deposit metal lithium to form a negative electrode active material film. Finally, magnetron sputtering is used to obtain a negative electrode current collector film, and an all-solid-state thin film lithium-ion battery is obtained after packaging.

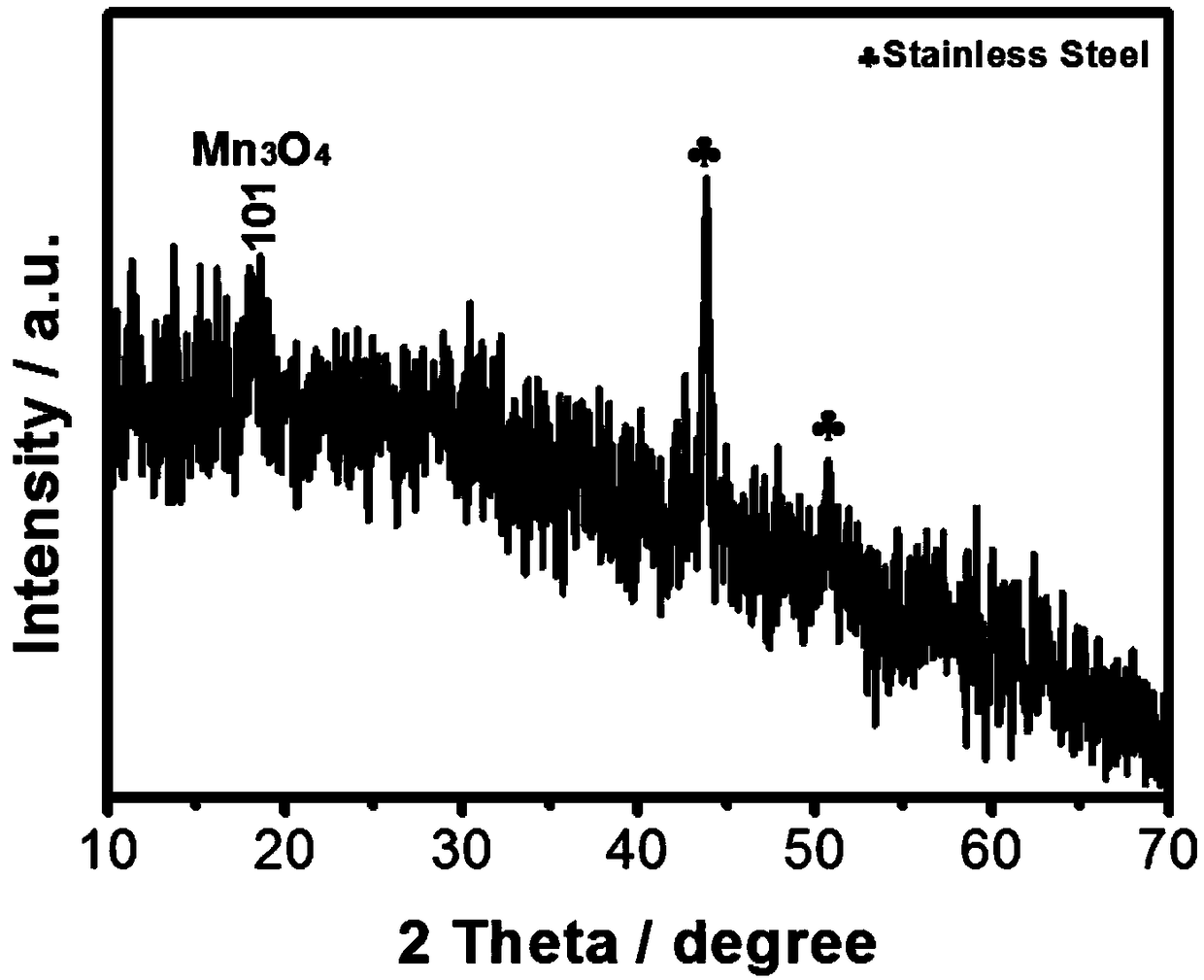

[0075] Figure 9 Mn in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com