Processing method for reducing carburizing and quenching deformation of helical gear

A technology of carburizing, quenching and processing methods, applied in the field of gear processing, which can solve problems such as high cost of grinding gears, failure of tooth surfaces to meet requirements, and reduction of gear rigidity, so as to reduce workload, ensure grinding quality, and reduce cutting volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

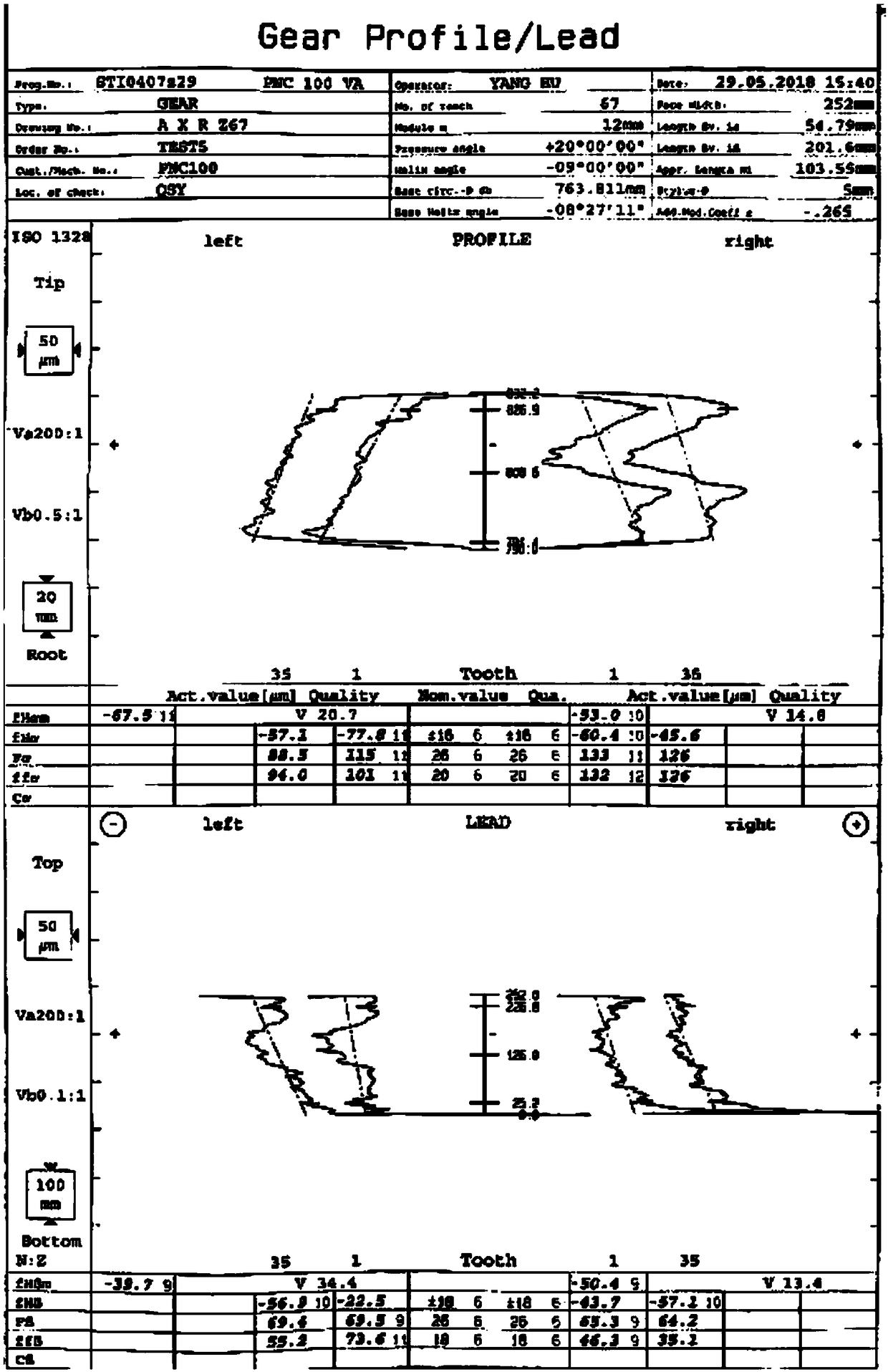

[0016] This embodiment discloses a processing method for reducing carburizing and quenching deformation of helical gears used in rail vehicle transmission systems, including the following steps: ① gear forging ② high temperature normalizing and high temperature tempering ③ semi-finishing turning ④ gear hobbing or gear shaping ⑤ infiltration Carbon quenching ⑥ finishing car ⑦ gear grinding ⑧ cleaning inspection.

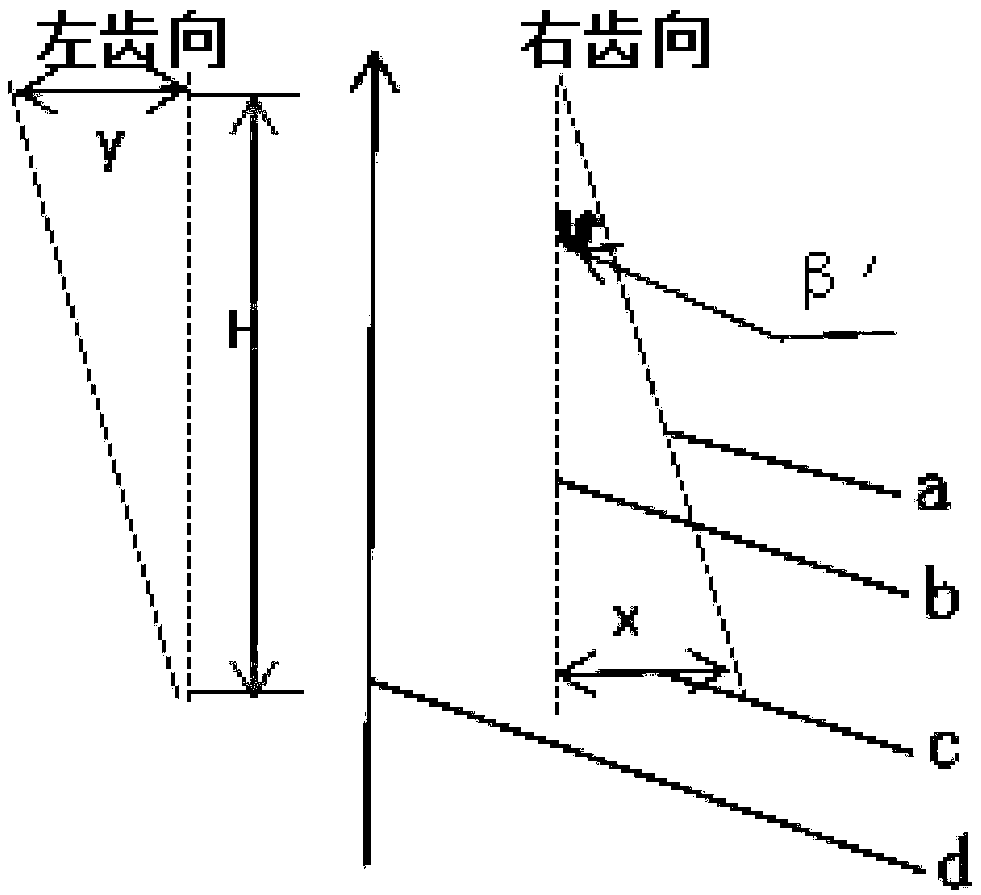

[0017] Before the carburizing and quenching process of the gear, reserve the anti-deformation helix angle margin β' for the helical gear processing, that is, the processing helix angle of the helical gear before the carburizing and quenching process is equal to the design helix angle β minus the anti-deformation The helix angle margin β'; the helix angle margin β' is set according to the design helix angle β of the gear, the effective analysis range H of the tooth direction of the gear and the heat treatment deformation M of the tooth direction in the gear hobbing or g...

Embodiment 2

[0022] This embodiment discloses a processing method for reducing carburizing and quenching deformation of helical gears used in rail vehicle transmission systems, including the following steps: ① gear forging ② high temperature normalizing and high temperature tempering ③ semi-finishing turning ④ gear hobbing or gear shaping ⑤ infiltration Carbon quenching ⑥ finishing car ⑦ gear grinding ⑧ cleaning inspection.

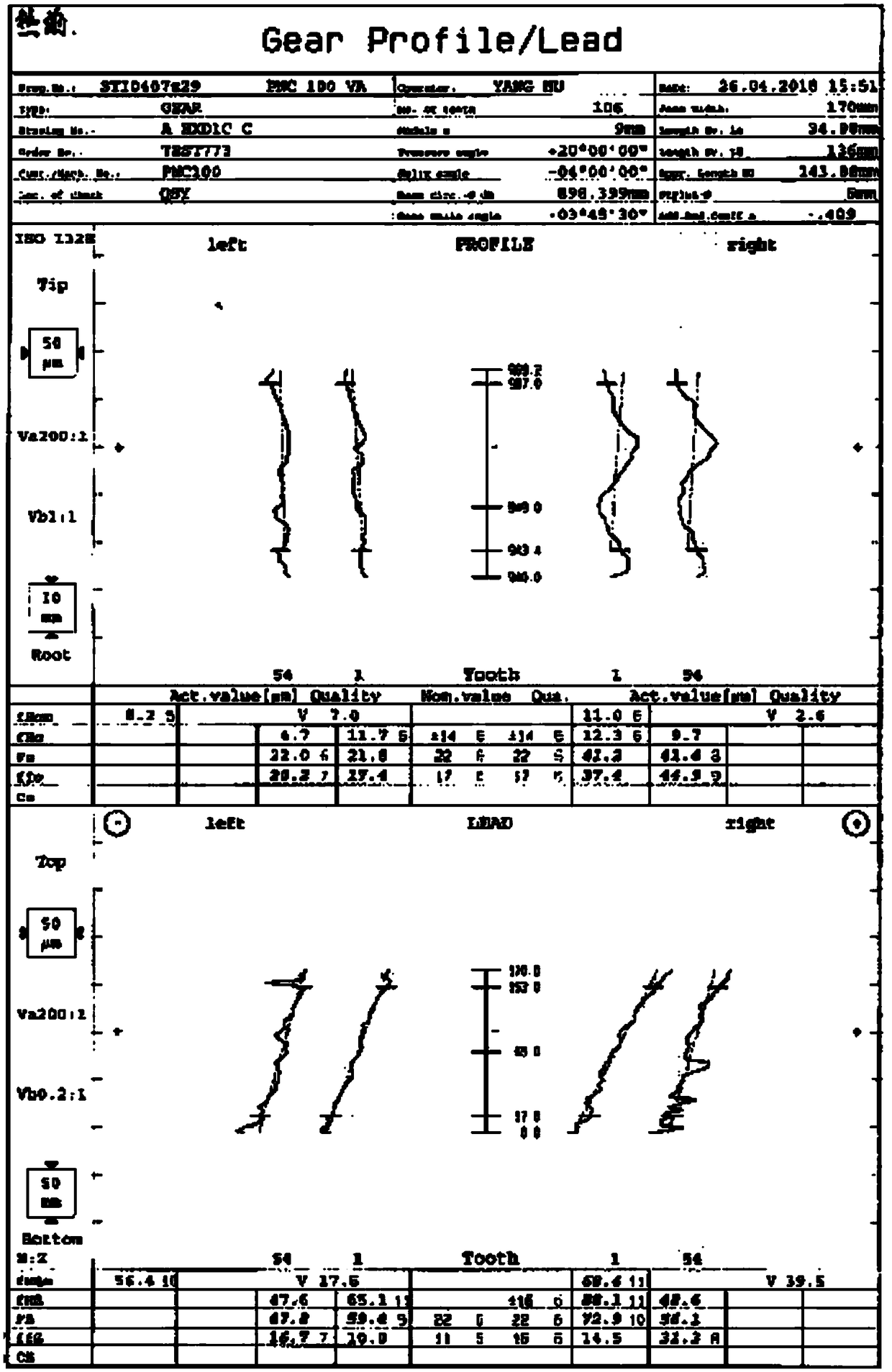

[0023] The gear parameters of this embodiment are as follows: the gear module is 9, the number of teeth is 106, the helix angle is 4° (left-handed), the pressure angle is 20°, and the tooth width is 170mm. According to the test report, the effective range of the tooth direction is H=153-17=136mm>100mm , before heat treatment, β100mm, so M≒(0.03~0.04)×(170÷100)≒0.051~0.68mm; M takes the median value of 0.0595mm; then β′=arctg( M / H)=arctg(0.0595 / 136)≒1′30″; so the helix angle of gear processing before heating should be 4°-1′30″=3°58′30″. The helix angle of gear processi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com