Ultraviolet intercepting thermoplastic polyolefin elastomer coating and application thereof

A thermoplastic and polyolefin technology, applied in the direction of film/sheet without carrier, adhesive, film/sheet adhesive, etc., can solve the problem of improving energy consumption and cost of photovoltaic module production, reducing production efficiency, lamination Problems such as high temperature, good UV cut-off performance, improved production efficiency, and low lamination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

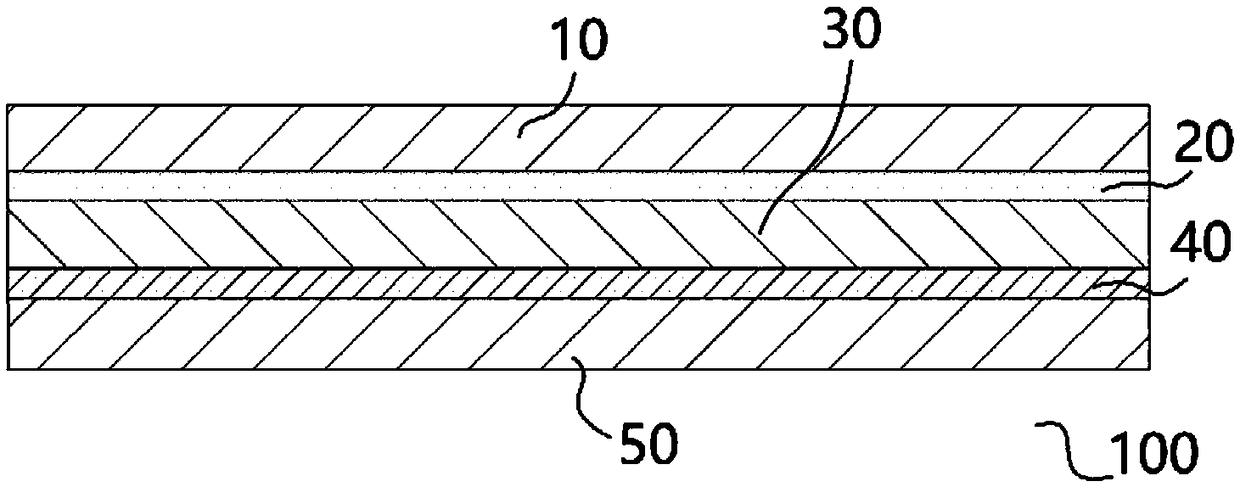

[0045] First, use 96.6g of polyolefin elastomer particles, 0.2g of phenolic antioxidant, 0.1g of phosphite antioxidant, 0.1g of sulfide antioxidant, 2g of nano-silica, and 0.6g of polymeric silane coupling agent. g, 0.2g of light stabilizer, 0.1g of organic ultraviolet absorber, and 0.1g of inorganic ultraviolet absorber to prepare the ultraviolet cut-off thermoplastic polyolefin elastomer film (I).

[0046] Then, the obtained ultraviolet cut-off thermoplastic polyolefin elastomer film (I) was laminated at a temperature of 150° C. for 10 minutes, and its damp heat aging yellowing value was 1.2 after the damp heat aging (double 85) test for 500 hours. After ultraviolet irradiation (60KWh), its ultraviolet aging yellowing value is 1.1, and the lamination peeling force between the ultraviolet cut-off thermoplastic polyolefin elastomer film (I) and the back sheet 50 can reach 143N / cm, for the wavelength range The light transmittance of the electromagnetic wave of 200nm-380nm can r...

Embodiment 2

[0048] First, use 96.8g of polyolefin elastomer particles, 0.1g of phenolic antioxidant, 0.1g of phosphite antioxidant, 0.1g of sulfide antioxidant, 3g of nano-silica, and 0.5g of polymeric silane coupling agent. g, 0.1 g of a light stabilizer, 0.1 g of an organic UV absorber, and 0.2 g of an inorganic UV absorber were prepared to obtain a UV-cut thermoplastic polyolefin elastomer film (II).

[0049] Then, the prepared ultraviolet cut-off thermoplastic polyolefin elastomer film (II) was laminated at a temperature of 150°C for 8 minutes, and tested for 500 hours by damp heat aging (double 85), the yellowing value of damp heat aging was 1.0, and after ultraviolet After irradiation (60KWh), the UV aging yellowing value is 1.0, and the lamination peeling force between the UV cut-off thermoplastic polyolefin elastomer film (Ⅱ) and the back sheet 50 can reach 135N / cm, for a wavelength range of 200nm The light transmittance of -380nm electromagnetic waves can reach 86.5%, and the lig...

Embodiment 3

[0051] First, use 96.9g of polyolefin elastomer particles, 0.3g of phenolic antioxidant, 0.4g of phosphite antioxidant, 0.2g of sulfide antioxidant, 1g of nano-silica, and 0.6g of polymeric silane coupling agent. g, 0.3 g of a light stabilizer, 0.2 g of an organic UV absorber, and 0.1 g of an inorganic UV absorber were prepared to obtain a UV-cut thermoplastic polyolefin elastomer film (Ⅲ).

[0052] Then, the prepared ultraviolet cut-off thermoplastic polyolefin elastomer film (Ⅲ) was laminated at 150°C for 8 minutes, and tested for 500 hours by damp heat aging (double 85), and the yellowing value of damp heat aging was 1.1. After irradiation (60KWh), the UV aging yellowing value is 1.0, and the lamination peeling force between the UV-cut thermoplastic polyolefin elastomer film (Ⅲ) and the back sheet 50 can reach 145N / cm, for a wavelength range of 200nm The light transmittance of electromagnetic waves at -380nm can reach 86.1%, and the light transmittance of electromagnetic wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com