A kind of preparation technology of waterborne epoxy resin anticorrosion coating

A water-based epoxy resin and anti-corrosion coating technology, which is applied in epoxy resin coatings, anti-corrosion coatings, anti-fouling/underwater coatings, etc., can solve the problems of lack of practicability and single function, and achieve strong light redox function, Faster removal and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

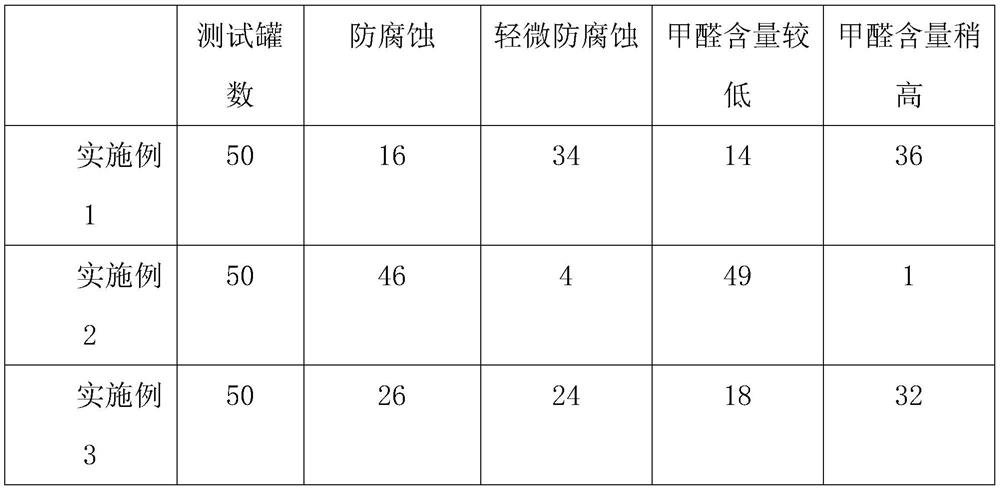

Embodiment 1

[0020] The invention provides a kind of water-based epoxy resin anticorrosion coating, comprising surface coating and primer, wherein the surface coating used comprises the following raw materials in parts by weight: 42 parts of water-based epoxy resin emulsion, 17 parts of water-based epoxy resin curing agent , 12 parts of deionized water, 10 parts of nano-scale titanium dioxide, 8 parts of activated carbon, 4 parts of UV varnish, 2 parts of colloidal copper catalyst, 4 parts of anti-rust grease No. 1, wherein the base coating used includes the following raw materials in parts by weight : 42 parts of water-based epoxy resin emulsion, 17 parts of water-based epoxy resin curing agent, 12 parts of deionized water, 16 parts of activated carbon, 26 parts of biological enzyme, 6 parts of anti-rust grease No. 1;

[0021] The present invention also provides a kind of preparation technology of waterborne epoxy resin anticorrosion coating, and concrete operation steps are:

[0022] Ste...

Embodiment 2

[0030] The invention provides a kind of water-based epoxy resin anticorrosion coating, comprising surface coating and bottom surface coating, wherein the surface coating used comprises the following raw materials in parts by weight: 40 parts of water-based epoxy resin emulsion, 16 parts of water-based epoxy resin curing agent , 11 parts of deionized water, 9 parts of nano-scale titanium dioxide, 7 parts of activated carbon, 3 parts of UV varnish, 1.5 parts of colloidal copper catalyst, 3 parts of anti-rust grease No. 1, wherein the base coating used includes the following raw materials in parts by weight : 40 parts of water-based epoxy resin emulsion, 16 parts of water-based epoxy resin curing agent, 11 parts of deionized water, 14 parts of activated carbon, 24 parts of biological enzyme, 5 parts of anti-rust grease No. 1;

[0031] The present invention also provides a kind of preparation technology of waterborne epoxy resin anticorrosion coating, and concrete operation steps a...

Embodiment 3

[0040]The invention provides a water-based epoxy resin anticorrosion coating, comprising a surface coating and a bottom coating, wherein the surface coating used includes the following raw materials in parts by weight: 38 parts of water-based epoxy resin emulsion, 15 parts of water-based epoxy resin curing agent , 10 parts of deionized water, 8-10 parts of nano-scale titanium dioxide, 6 parts of activated carbon, 2 parts of UV varnish, 1 part of colloidal copper catalyst, 2 parts of No. 1 rust-proof grease, wherein the bottom surface coating used includes the following parts by weight Raw materials: 38 parts of water-based epoxy resin emulsion, 15 parts of water-based epoxy resin curing agent, 10 parts of deionized water, 12 parts of activated carbon, 22 parts of biological enzyme, 4 parts of anti-rust grease No. 1;

[0041] The present invention also provides a kind of preparation technology of waterborne epoxy resin anticorrosion coating, and concrete operation steps are:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com