A kind of ceramic ferrule and preparation method thereof

A ceramic ferrule and ceramic powder technology, which is applied in the field of ceramic ferrule and its preparation, can solve the problems that the anti-aging performance needs to be further improved, zirconia ceramics are easy to deform, and it is difficult to ensure accuracy and strength, so as to achieve equipment dependence Not high, the preparation method is simple and easy, and the effect of improving the bonding performance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

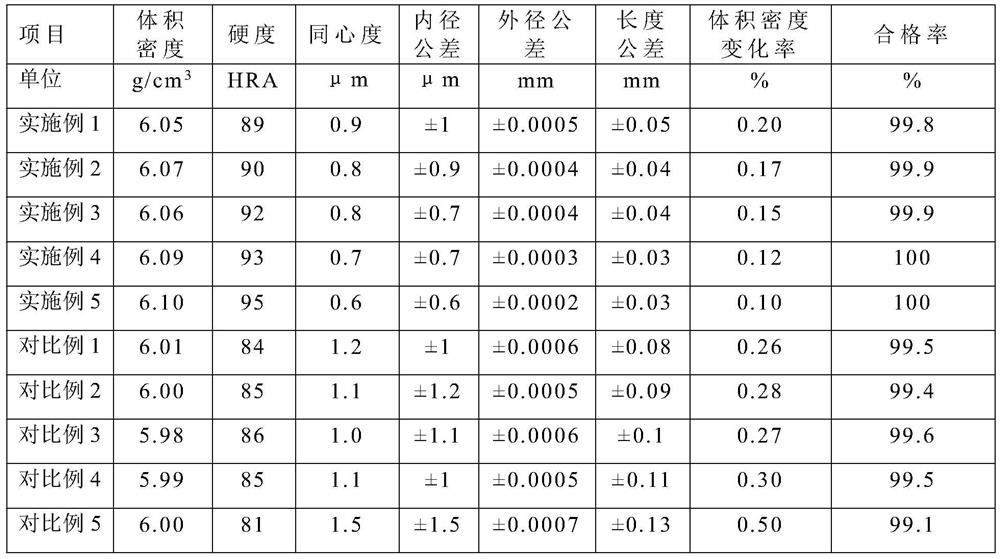

Examples

Embodiment 1

[0028] A ceramic ferrule, made of the following raw materials in parts by weight: 100 parts of ceramic powder, 20 parts of organic carrier; the ceramic powder includes the following components: zirconium oxide, hafnium oxide, praseodymium oxide, manganese oxide, terbium oxide ; The organic vehicle includes the following components: polyethylene terephthalate, ethylene acrylic acid copolymer, polyethylene wax, based on vegetable oil siloxane-based acrylate copolymer; the vegetable oil siloxane-based acrylate Copolymers are made of vegetable oil, sodium salt of 4-dodecyl-1-(2-propenyl) sulfosuccinate, poly(ethylene glycol) phenyl ether acrylic acid, bis(3-trimethoxy Silylpropyl) (E)-but-2-enedioate is prepared by copolymerization.

[0029] The parts by weight ratio of each component of the ceramic powder is: 90 parts of zirconium oxide, 1 part of hafnium oxide, 1 part of praseodymium oxide, 1 part of manganese oxide, and 1 part of terbium oxide.

[0030] The weight-to-number ra...

Embodiment 2

[0040] A ceramic ferrule, made of the following raw materials in parts by weight: 100 parts of ceramic powder, 23 parts of organic carrier; the ceramic powder includes the following components: zirconium oxide, hafnium oxide, praseodymium oxide, manganese oxide, terbium oxide ; The organic vehicle includes the following components: polyethylene terephthalate, ethylene acrylic acid copolymer, polyethylene wax, based on vegetable oil siloxane-based acrylate copolymer; the vegetable oil siloxane-based acrylate Copolymers are made of vegetable oil, sodium salt of 4-dodecyl-1-(2-propenyl) sulfosuccinate, poly(ethylene glycol) phenyl ether acrylic acid, bis(3-trimethoxy Silylpropyl) (E)-but-2-enedioate is prepared by copolymerization.

[0041] The weight-to-number ratios of the components of the ceramic powder are: 92 parts of zirconia, 1.5 parts of hafnium oxide, 1.5 parts of praseodymium oxide, 1.5 parts of manganese oxide, and 1.5 parts of terbium oxide.

[0042] The weight-to-n...

Embodiment 3

[0052] A ceramic ferrule, made of the following raw materials in parts by weight: 100 parts of ceramic powder, 25 parts of organic carrier; the ceramic powder includes the following components: zirconium oxide, hafnium oxide, praseodymium oxide, manganese oxide, terbium oxide ; The organic vehicle includes the following components: polyethylene terephthalate, ethylene acrylic acid copolymer, polyethylene wax, based on vegetable oil siloxane-based acrylate copolymer; the vegetable oil siloxane-based acrylate Copolymers are made of vegetable oil, sodium salt of 4-dodecyl-1-(2-propenyl) sulfosuccinate, poly(ethylene glycol) phenyl ether acrylic acid, bis(3-trimethoxy Silylpropyl) (E)-but-2-enedioate is prepared by copolymerization.

[0053] The parts by weight ratio of each component of the ceramic powder is: 93 parts of zirconium oxide, 2 parts of hafnium oxide, 2 parts of praseodymium oxide, 2 parts of manganese oxide and 2 parts of terbium oxide.

[0054] The weight-to-number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com