Ecological cement-based concrete reinforcing coating and preparation method thereof

A technology of ecological cement and concrete, which is applied in the field of architectural coatings in the field of industrial and civil construction, can solve the problems of complex components and unenvironmental protection of raw materials, and achieve the effects of improving microstructure, good crack repair effect, and small aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

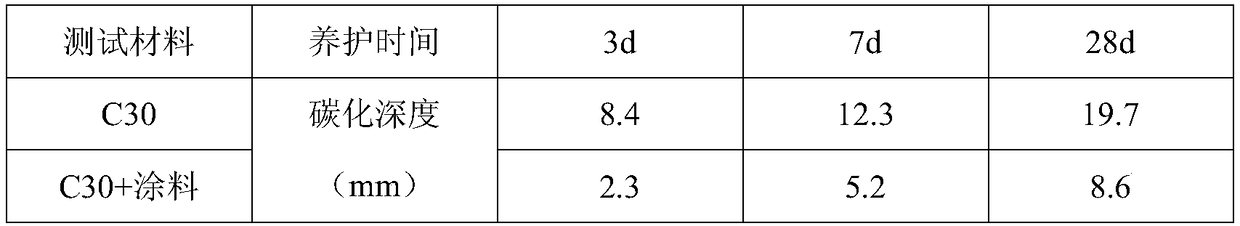

Image

Examples

Embodiment 1

[0029] An ecological cement-based concrete reinforced coating is prepared by mixing solid and liquid two-phase components. According to the weight percentage, its raw materials are composed of:

[0030] Solid phase components: 38% cement, 9% silica fume, 18% fly ash, 10% limestone powder;

[0031] Liquid phase components: 20% water, 4% water reducer, 1% defoamer.

[0032] The cement in the solid phase component is one or both of ordinary portland cement and rapid hardening aluminate iron cement, and the strength grade of the cement is not less than 32.5. In this embodiment, the cement used is P.O42. 5 Portland cement.

[0033] The silica fume in the solid phase component is SiO produced by high temperature smelting 2 It is an amorphous ultrafine active silica fume formed by rapid oxidation and condensation with Si gas and oxygen in the air. Silica fume is an industrial by-product that can significantly improve compressive, flexural, impermeable, anti-corrosion and abrasion ...

Embodiment 2

[0118] An ecological cement-based concrete reinforced coating is prepared by mixing solid and liquid two-phase components. According to the weight percentage, its raw materials are composed of:

[0119] Solid phase components: 35% cement, 10% silica fume, 15% fly ash, 15% limestone powder;

[0120] Liquid phase components: 20% water, 3% water reducer, 3% defoamer.

[0121] In this example, each component can be purchased through commercial channels, and the sources of each component are the same as in Example 1.

[0122] A preparation method for ecological cement-based concrete reinforced coating, comprising the following steps:

[0123] (1) Mix cement, silica fume, fly ash, and limestone powder in the solid phase, and mechanically stir for 25 to 30 minutes to make it evenly mixed;

[0124] (2) Add water and stir mechanically for 3-5 minutes, at this time, the mixture is a slightly moist powder;

[0125] (3) Add the admixture and perform mechanical stirring for 10 minutes t...

Embodiment 3

[0144] An ecological cement-based concrete reinforced coating is prepared by mixing solid and liquid two-phase components. According to the weight percentage, its raw materials are composed of:

[0145] Solid phase components: 40% cement, 5% silica fume, 20% fly ash, 10% limestone powder;

[0146] Liquid phase components: 25% water, 1% water reducer, 3% defoamer.

[0147] In this example, each component can be purchased through commercial channels, and the sources of each component are the same as in Example 1.

[0148] A preparation method for ecological cement-based concrete reinforced coating, comprising the following steps:

[0149] (1) Mix cement, silica fume, fly ash, and limestone powder in the solid phase, and mechanically stir for 25 to 30 minutes to make it evenly mixed;

[0150] (2) Add water and stir mechanically for 3-5 minutes, at this time, the mixture is a slightly moist powder;

[0151] (3) Add the admixture and perform mechanical stirring for 10 minutes to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Surface diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com