Electroplating wastewater treatment system for circuit board

A technology of electroplating wastewater and treatment system, which is applied in the field of environmental protection technology, can solve the problems of ineffective filtration of sediment, unfavorable evolution of electroplating wastewater, etc., and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

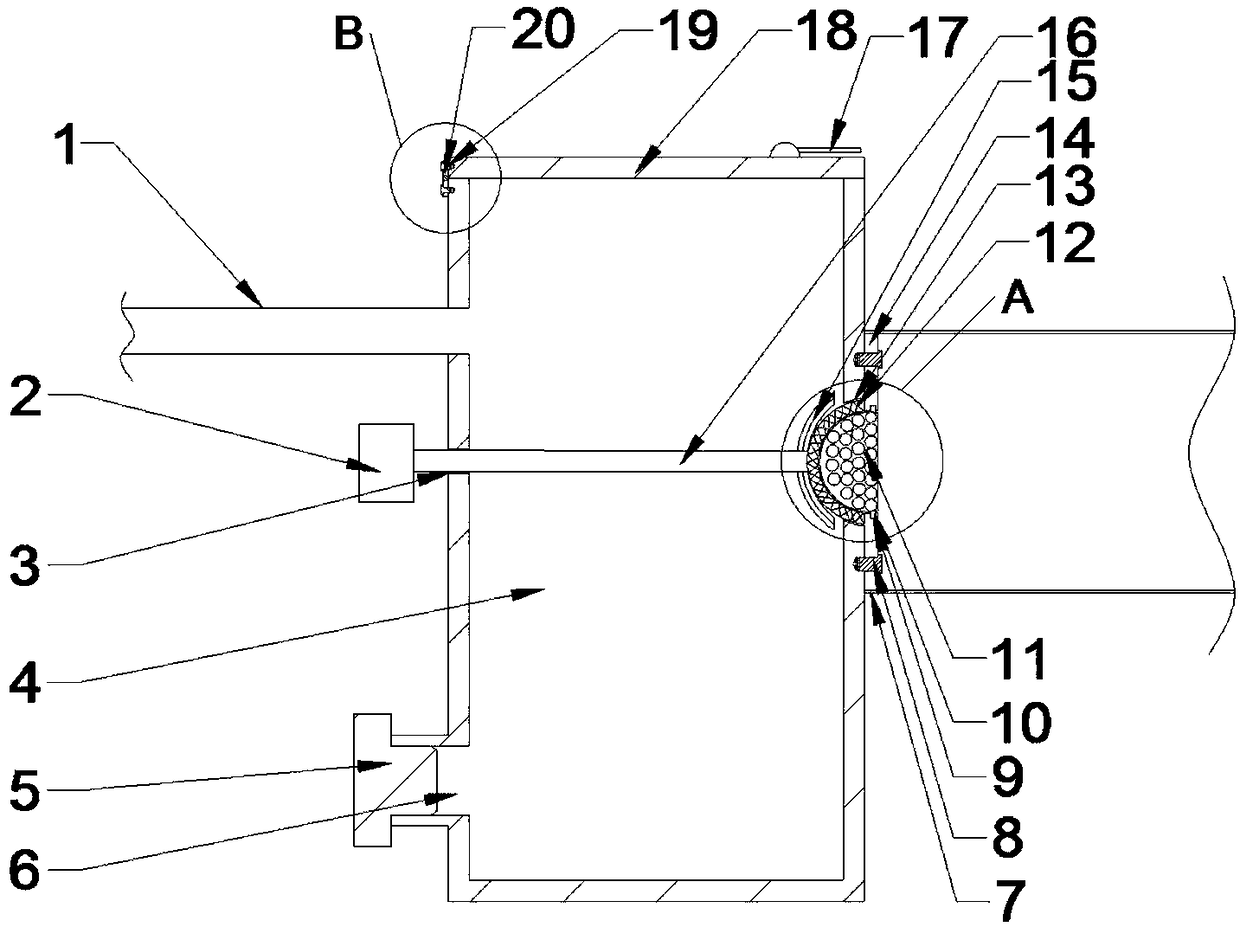

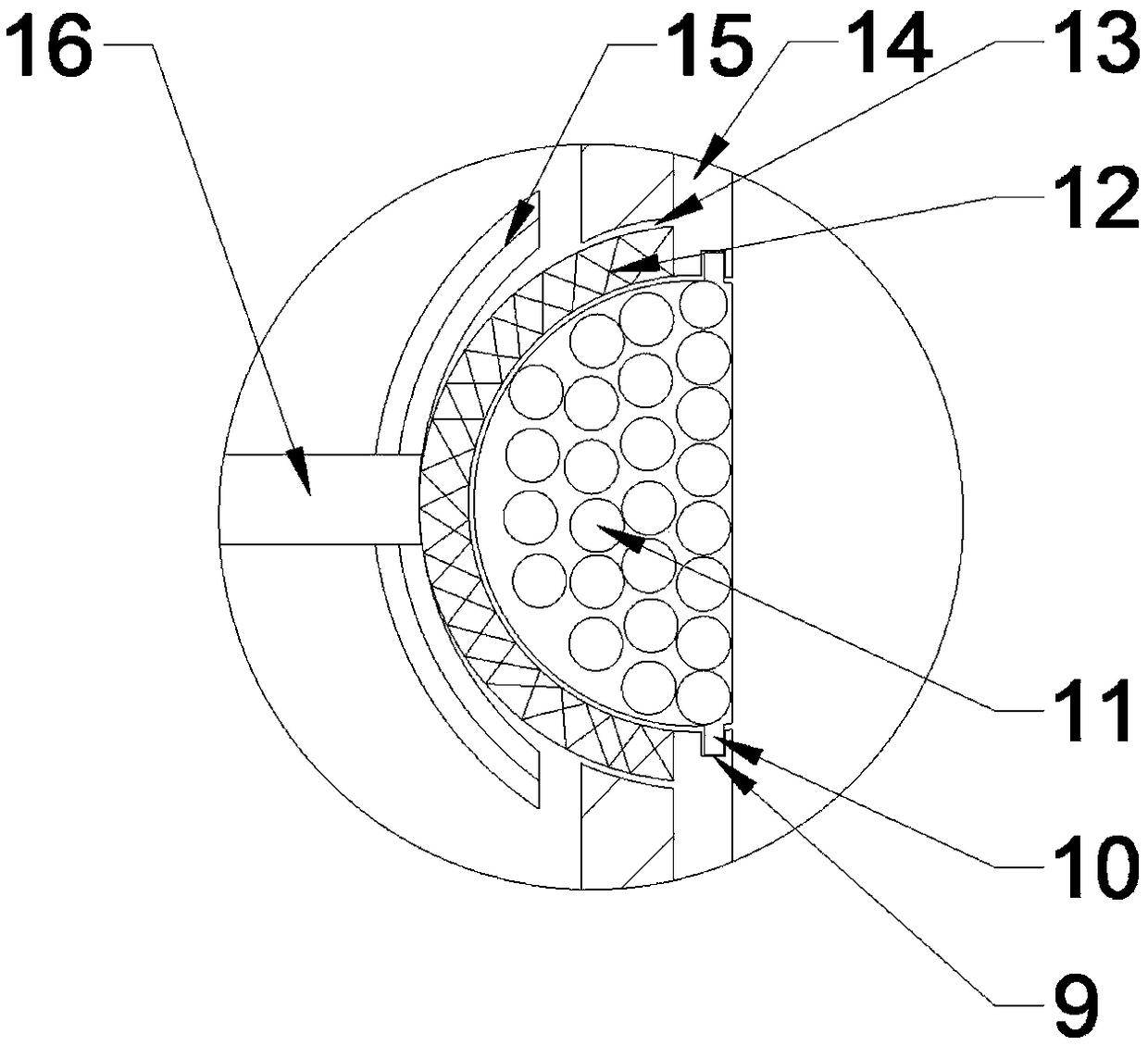

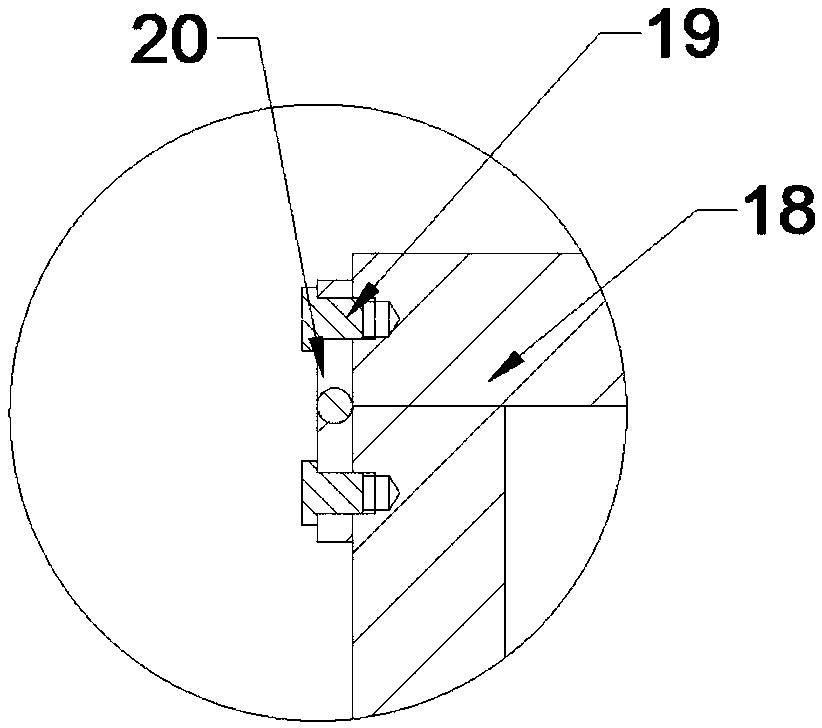

[0032] see Figure 1~3 , a circuit board electroplating wastewater treatment system, comprising a reaction box 4, the upper part of the left side wall of the reaction box 4 is provided with a liquid inlet pipe 1, the middle of the rear wall of the reaction box 4 is provided with a socket 3, and the socket 3 is provided with Rotary shaft 16, the end of rotating shaft 16 positioned at the outside of the casing is connected with motor 2, and the end of the rotating shaft 16 box positioned at the inside of the body is provided with an arc-shaped brush bar 15, and the arc-shaped brush bar 15 is fixed on the rotating shaft 16; The right side box wall of case 4 is provided with drain hole 13, is inserted with the hemispherical filter screen 12 with fixed seat 14 in the drain hole 13, and the surface of hemispherical filter screen 12 contacts with arc-shaped hairbrush bar 15, and the hemispherical body The fixed seat 14 of filter screen 12 is connected and fixed on the reaction box 4 ...

Embodiment 2

[0035] see Figure 1~3 , a circuit board electroplating wastewater treatment system, comprising a reaction box 4, the upper part of the left side wall of the reaction box 4 is provided with a liquid inlet pipe 1, the middle of the rear wall of the reaction box 4 is provided with a socket 3, and the socket 3 is provided with Rotary shaft 16, the end of rotating shaft 16 positioned at the outside of the casing is connected with motor 2, and the end of the rotating shaft 16 box positioned at the inside of the body is provided with an arc-shaped brush bar 15, and the arc-shaped brush bar 15 is fixed on the rotating shaft 16; The right side box wall of case 4 is provided with drain hole 13, is inserted with the hemispherical filter screen 12 with fixed seat 14 in the drain hole 13, and the surface of hemispherical filter screen 12 contacts with arc-shaped hairbrush bar 15, and the hemispherical body The fixed seat 14 of filter screen 12 is connected and fixed on the reaction box 4 ...

Embodiment 3

[0041] see Figure 1~3 , a circuit board electroplating wastewater treatment system, comprising a reaction box 4, the upper part of the left side wall of the reaction box 4 is provided with a liquid inlet pipe 1, the middle of the rear wall of the reaction box 4 is provided with a socket 3, and the socket 3 is provided with Rotary shaft 16, the end of rotating shaft 16 positioned at the outside of the casing is connected with motor 2, and the end of the rotating shaft 16 box positioned at the inside of the body is provided with an arc-shaped brush bar 15, and the arc-shaped brush bar 15 is fixed on the rotating shaft 16; The right side box wall of case 4 is provided with drain hole 13, is inserted with the hemispherical filter screen 12 with fixed seat 14 in the drain hole 13, and the surface of hemispherical filter screen 12 contacts with arc-shaped hairbrush bar 15, and the hemispherical body The fixed seat 14 of filter screen 12 is connected and fixed on the reaction box 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com