Spiral-flow type reflux hydrolytic acidification reactor

An acidification reactor and reactor technology, applied in the direction of water distribution pipes, anaerobic digestion treatment, etc., can solve the problems of low operating efficiency, muddy water, insufficient mixing of muddy water, etc., and achieve the effect of improving reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

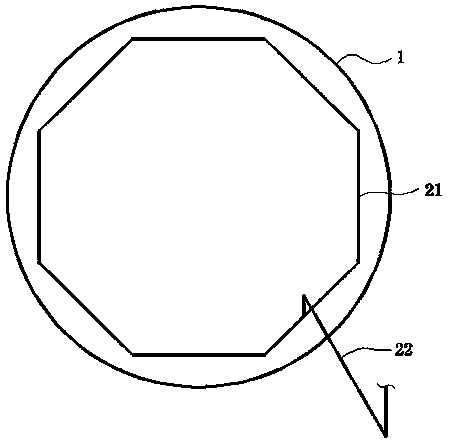

[0030] refer to Figure 1-5 , a swirl type reflux hydrolysis acidification reactor, comprising a reactor body 1, the top of the reactor body 1 is connected with an outlet weir 2, the outlet weir 2 is connected with an outlet pipe 3, and the upper end of the reactor body 1 is internally connected with a retaining ring 4 , the bottom of the reactor body 1 is arranged with a mud discharge pipe 21, the mud discharge pipe 21 is connected with a mud discharge pipe 22, and a PE baffle assembly 5 is arranged inside the upper end of the reactor body 1, and the PE baffle assembly 5 is located in the retaining ring 4, the bottom of the reactor body 1 is provided with a first PE water distribution pipe 18 and a second PE water distribution pipe 17, and the first PE water distribution pipe 18 and the second PE water distribution pipe 17 are respectively connected with a first water spray head 20 and a second PE water distribution pipe 17. Water spray head 19; through the first PE water dis...

Embodiment 2

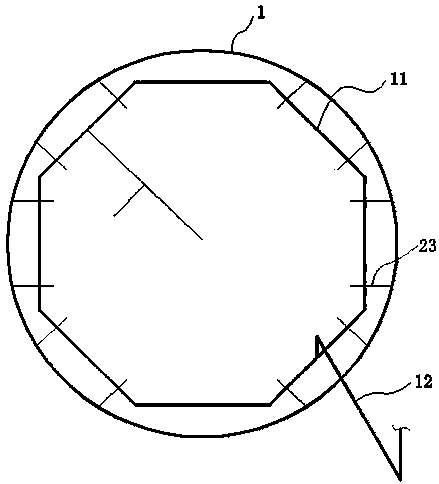

[0032] refer to Figure 1-8, a swirl type reflux hydrolysis acidification reactor, which is basically the same as in Example 1, the difference is that the first PE water distribution pipe 18 and the second PE water distribution pipe 17 are connected with the first water inlet pipe 16 and the second water inlet pipe 17 respectively. The water pipe 15, the upper end of the reactor body 1 is arranged with a return water distribution perforated pipe 11, the return water distribution perforated pipe 11 is connected with the second water inlet pipe 15 through the return pipe 12, the return pipe 12 is connected with a pressurized water pump 13, the first PE cloth The water pipe 18 and the second PE water distribution pipe 17 are respectively connected with the first water inlet pipe 16 and the second water inlet pipe 15, and the upper end of the reactor body 1 is arranged with a return water distribution perforated pipe 11, and the return water distribution perforated pipe 11 passes t...

Embodiment 3

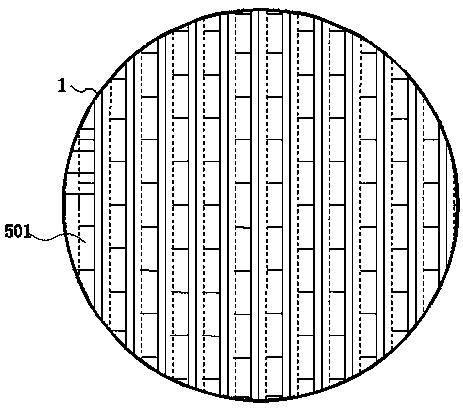

[0035] refer to Figure 4-5 , a swirl type reflux hydrolysis acidification reactor, which is basically the same as Example 1, the difference is that the PE baffle assembly 5 includes an angle iron 501, a folded plate 504, a fixed support rod 502, and the folded plate 504 is fixedly connected to On the angle iron 501, the folded plate 504 is fixedly connected to the angle iron 501 through the fixed support rod 502, and the angle iron 501 is fixedly connected with a support seat 503, and the upper end of the support seat 503 is offset against the bottom side of the bend of the fold plate 504, and the angle iron 501 facilitates the stable connection of the flap 504 to the reactor body 1. When the three-item mixture of mud, water and air enters the PE baffle assembly 5, the flap 504 is used to block the water, and the water collects on the top of the flap 504, and the mud and Water enters the outside of the folded plate 504 and moves upward, where it is blocked by the folded plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com