Preparation method and application of high-purity medium-temperature coal pitch based super active carbon

A technology of coal tar and activated carbon, which is applied in the field of preparation of high-purity medium-temperature coal tar-based super activated carbon, can solve the problems of high self-discharge, poor cycle performance of electrode materials, etc., achieves developed pore structure, simple and easy preparation method, and realizes preparation and applied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

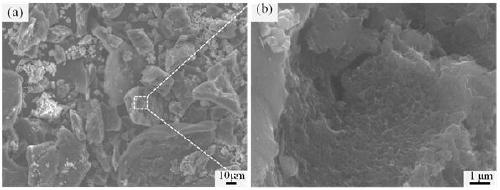

[0036] (1) Weigh 10g block with a softening point of 125 o C, medium-temperature coal tar pitch with an ash content of about 15%, crushed into powder with a mortar, and sieved with an 80-mesh stainless steel screen to obtain medium-temperature coal tar pitch particles with a particle size of less than 180 μm;

[0037] (2) Weigh 6g of the above medium-temperature coal tar pitch particles, mix with 50ml of hydrochloric acid solution with a concentration of 3mol / L, and mix them at 80 o C under heating and stirring for 3h, using a water ring vacuum pump to filter, constantly using deionized water to wash until the filtrate reaches neutrality, and then at 100 o Blast drying under C for 8h to obtain pretreated medium temperature coal tar pitch particles;

[0038] (3) Weigh 4g of the above pretreated sample and mix it with 40ml of 10% hydrofluoric acid solution at 80 oFully heated and stirred at ℃ for 3h, filtered by water ring vacuum pump, washed with deionized water continuously ...

Embodiment 2

[0048] (1) Weigh 8g block with a softening point of 130 o C, medium-temperature coal tar pitch with an ash content of about 10%, crushed into powder with a mortar, and sieved with a 100-mesh stainless steel screen to obtain medium-temperature coal tar pitch particles with a particle size of less than 150 μm;

[0049] (2) Weigh 6g of the above medium-temperature coal tar pitch particles, mix with 30ml of hydrochloric acid solution with a concentration of 6mol / L, and mix them at 90 o C under heating and stirring for 2 h, using a water ring vacuum pump to filter, constantly using deionized water to wash until the filtrate reaches neutrality, and then at 80 o Blast drying under C for 10h to obtain pretreated medium temperature coal tar pitch particles;

[0050] (3) Weigh 3g of the above pretreated sample and mix it with 15ml of 20% hydrofluoric acid solution. o Fully heated and stirred for 5 hours at C, filtered with a water ring vacuum pump, washed with deionized water continuo...

Embodiment 3

[0056] (1) Weigh 12g block with a softening point of 100 o C, medium-temperature coal tar pitch with an ash content of about 20%, crushed into powder with a mortar, and sieved with a 100-mesh stainless steel screen to obtain medium-temperature coal tar pitch particles with a particle size of less than 150 μm;

[0057] (2) Weigh 10g of the above medium-temperature coal tar pitch particles, mix with 200ml of hydrochloric acid solution with a concentration of 2mol / L, and mix them at 60 o C under heating and stirring for 5h, using a water ring vacuum pump to filter, constantly using deionized water to wash in the filtering process until the filtrate reaches neutrality, and then at 120 o C under air blast drying 5h, obtains the medium temperature coal tar pitch particle of pretreatment;

[0058] (3) Weigh 7g of the above pretreated sample and mix it with 100ml of 8% hydrofluoric acid solution at 90 o Fully heated and stirred for 2 hours at C, filtered with a water ring vacuum pum...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com