Method for preparing zeolite by using sintered bed mud as material

A technology of bottom sludge and zeolite, which is applied in the direction of crystalline aluminosilicate zeolite, chemical instruments and methods, sludge treatment, etc., can solve the problems that sintered bottom sludge does not have a competitive advantage, is difficult to promote, and has low added value, and achieves High added value, realization of resources, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

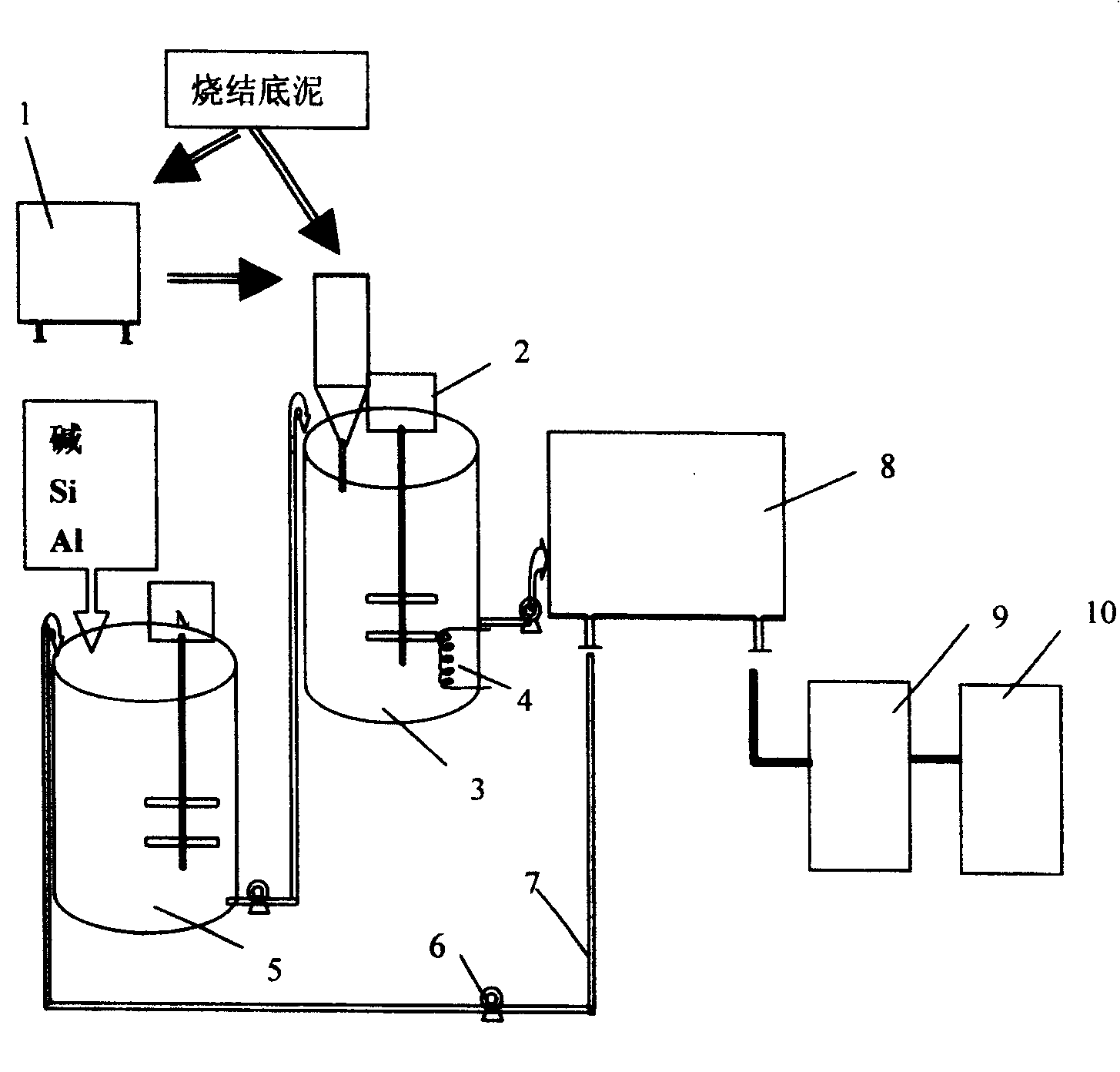

[0017] The traditional hydrothermal synthesis method is adopted, so the synthesis reaction does not go through the melting furnace, but the raw materials and ingredients are directly put into the zeolite synthesis reaction tank 3 .

[0018] The raw material is sintered bottom sludge, that is, the sludge under water bodies such as rivers and lakes after sintering in an aerobic or reducing atmosphere at medium temperature (500-900°C) or high temperature (900-2000°C). The ingredients are sodium silicate and table salt, wherein the sodium silicate is 10% of the weight of the sintered bottom mud, and the table salt is 20% of the weight of the sintered bottom mud. Prepare a 2.5M (molar concentration) NaOH solution in the dissolving tank 5, send it into the zeolite synthesis reaction tank 3 with a metering pump at a solid-to-liquid ratio of 1:4, fully mix it with the stirring device 2, and use the heating device 4 to synthesize the zeolite The contents of the reaction tank were kept ...

Embodiment 2

[0020] The traditional hydrothermal synthesis method is adopted, so the synthesis reaction does not go through the melting furnace, but the raw materials and ingredients are directly put into the zeolite synthesis reaction tank 3 . The raw material is sintered bottom mud, and the ingredients are metal aluminum foil and sodium fluoride, wherein the aluminum foil is 5% of the weight of the sintered bottom mud, and the sodium fluoride is 15% of the weight of the sintered bottom mud. Prepare a 1.5M (molar concentration) NaOH solution in the dissolving tank 5, send it into the zeolite synthesis reaction tank 3 with a metering pump at a solid-to-liquid ratio of 1:6, fully mix it with the stirring device 2, and use the heating device 4 to synthesize the zeolite The contents of the reaction tank were kept at a temperature of 200° C., and reacted under this condition for 2 hours. The reaction product was sent into the dehydration tank 8 for solid-liquid separation with a metering pump, ...

Embodiment 3

[0022] A two-step synthesis method is adopted, the raw material is sintered bottom sludge, and the ingredients are solid NaOH and metal aluminum foil, wherein the dosage of solid NaOH is the same as that of the sintered bottom sludge, and the added amount of aluminum foil is 5% of the weight of the sintered bottom sludge. Raw ingredients are put into the melting furnace 1, the melting temperature is 500° C., and the melting time is 1 hour. The melted material is transferred to the zeolite synthesis reaction tank 3. The production water contained in the dissolving tank 5 is sent into the reaction tank 3 with a metering pump at a solid-to-liquid ratio of 1:8. Fully mix with the stirring device 2, keep the content of the zeolite synthesis reaction tank at a temperature of 90°C with the heating device 4, and keep it under this condition for 2 hours, and send the reaction product into the dehydration tank 8 for solid-liquid separation with a metering pump, where The solid and liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com