Compound elevator traction belt

A technology of elevator traction and traction belt, which is applied in the field of elevator traction belt and composite elevator traction belt, and can solve the problems of complicated preparation process of traction belt, reduction of bending radius of traction belt, reduction of diameter of traction shaft, etc. , to achieve the effect of light weight, saving building space and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

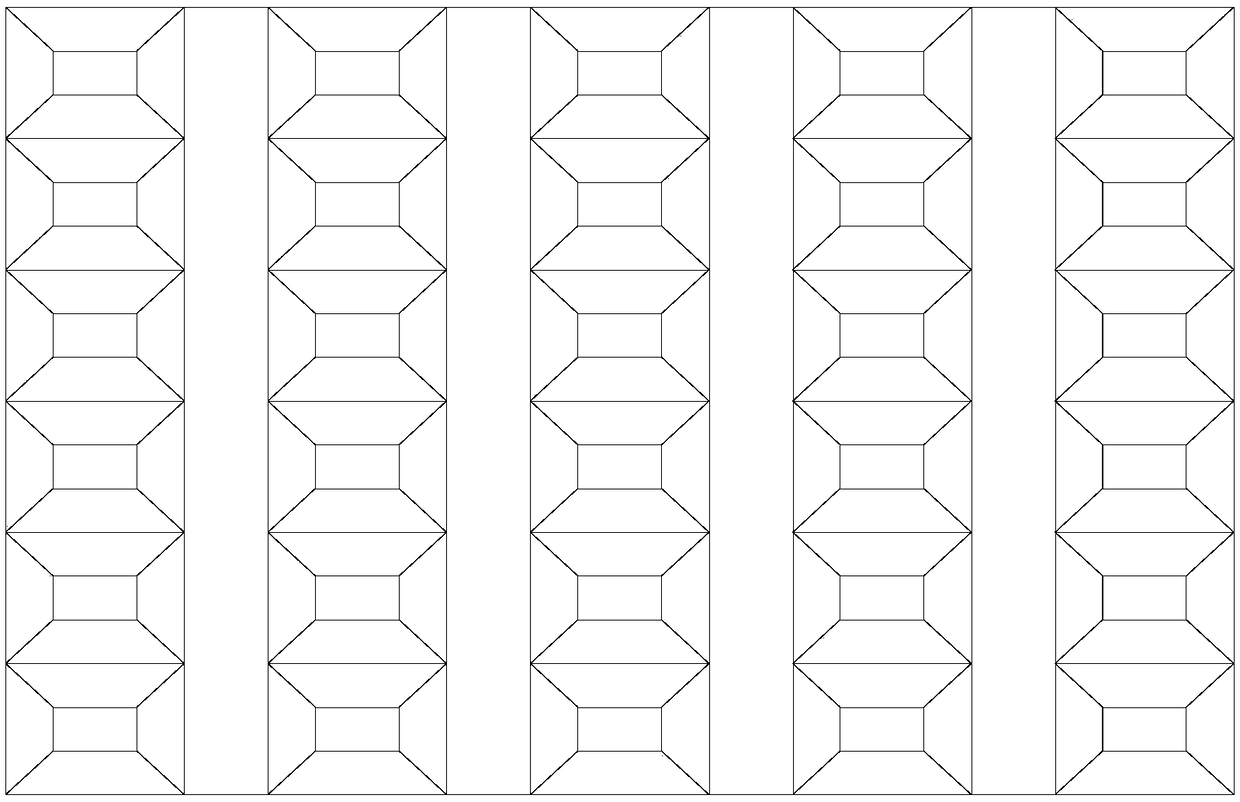

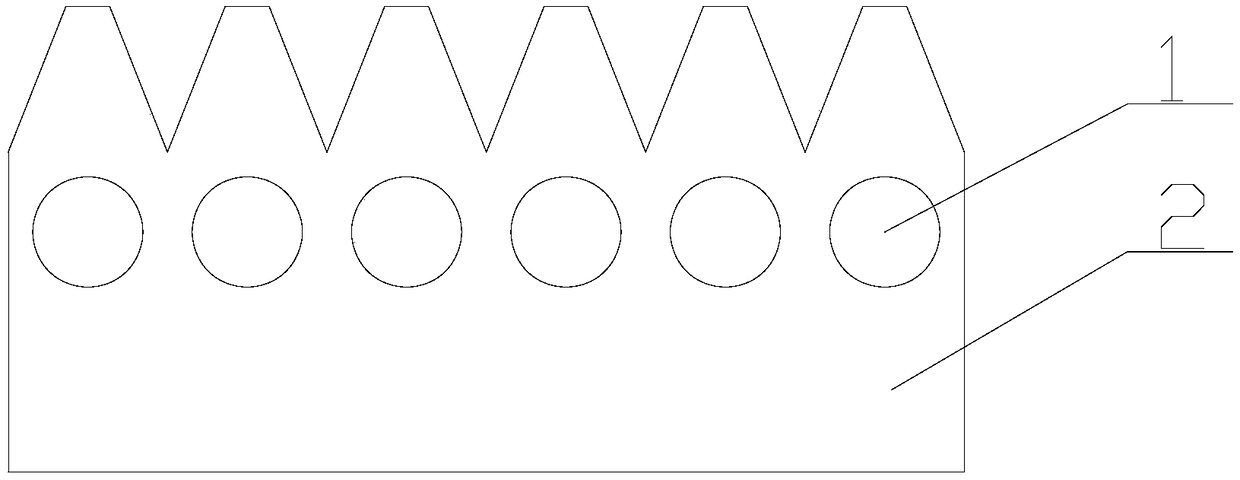

[0032] A composite elevator traction belt, the traction belt has high flexibility, such as figure 1 and figure 2 As shown, it includes a high-strength aramid rope 1 in the middle and a surface thermoplastic polyurethane layer 2 covering the outside of the aramid rope. The surface of the thermoplastic polyurethane layer 2 is provided with a wedge-shaped structure parallel to the longitudinal direction of the traction belt, and the wedge-shaped structure is provided with a tooth-shaped structure; the back of the traction belt is a matte structure.

[0033] Among them, the aramid rope is made by twisting several strands of aramid fiber and carbon fiber; the aramid fiber is a long fiber, and the length of a single fiber is greater than 3000m; the tensile strength of the aramid rope is 6KN / root, and the elongation at break is was 2.4%. The carbon fiber is a certain amount of conductive continuous carbon fiber; the thermoplastic polyurethane layer has a hardness of 85A, the total...

Embodiment 2

[0037] A composite elevator traction belt, which has high flexibility, includes a middle high-strength aramid fiber rope 1 and a surface thermoplastic polyurethane layer 2 wrapped outside the aramid fiber rope. The surface of the thermoplastic polyurethane layer 2 is provided with a wedge-shaped structure parallel to the longitudinal direction of the traction belt, and the wedge-shaped structure is provided with a tooth-shaped structure; the back of the traction belt is a matte structure.

[0038] Among them, the aramid rope is made by twisting several strands of aramid fiber and carbon fiber; the aramid fiber is a long fiber, and the length of a single fiber is greater than 3000m; the tensile strength of the aramid rope is 5.5KN / root, and the elongation at break The rate is 2%. The carbon fiber is a certain amount of conductive continuous carbon fiber; the thermoplastic polyurethane layer has a hardness of 85A, the total thickness of the traction belt is 5mm, and the width of...

Embodiment 3

[0041] A composite elevator traction belt, which has high flexibility, includes a middle high-strength aramid fiber rope 1 and a surface thermoplastic polyurethane layer 2 wrapped outside the aramid fiber rope. The surface of the thermoplastic polyurethane layer 2 is provided with a wedge-shaped structure parallel to the longitudinal direction of the traction belt, and the wedge-shaped structure is provided with a tooth-shaped structure; the back of the traction belt is a matte structure.

[0042] Among them, the aramid rope is made by twisting several strands of aramid fiber and carbon fiber; the aramid fiber is a long fiber, and the length of a single fiber is greater than 3000m; the tensile strength of the aramid rope is 7KN / root, and the elongation at break is 1.5%. The carbon fiber is a certain amount of conductive continuous carbon fiber; the thermoplastic polyurethane layer has a hardness of 85A, the total thickness of the traction belt is 4mm, and the width of the trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com