A belt conveyor anti-deviation device

A belt conveyor and anti-deviation technology, which is applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of high cost, affecting normal production, low efficiency, etc., achieve low cost, solve anti-deviation, The effect of reducing belt wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

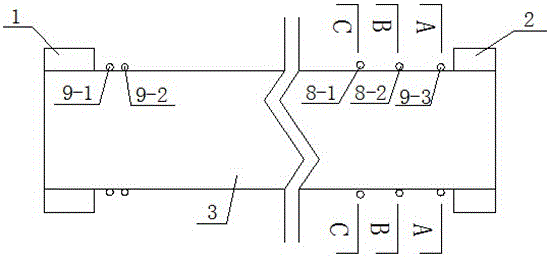

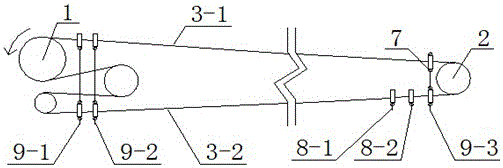

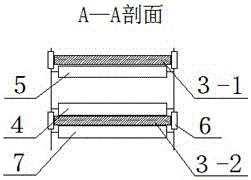

[0021] A belt conveyor anti-deviation device (see figure 1 with figure 2 , figure 2 The direction of the arrow in the belt indicates the running direction of the belt), which includes the belt drive wheel 1, the belt tail wheel 2 and the belt 3, and the first limit and calibration device 9-1 and the second limit and calibration device are installed behind the belt drive wheel 1 Device 9-2, a first calibration device 8-1 is installed in front of the belt tail pulley 2, a second calibration device 8-2 and a third limit and calibration device 9-3 are provided, and the first and second calibration devices are arranged behind the belt drive pulley 1. The limit and calibration device can ensure that the belt entering and leaving the drive wheel 1 does not shift in position, and the first and second calibration devices and the third limit and calibration device are installed in front of the belt tail wheel 2 to ensure that the belt enters and drives away from the belt tail The be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com