Six-axis welding robot

A welding robot and robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of the decrease of the degree of freedom of the six-axis joint industrial welding robot, and achieve strong intuition, convenient operation, high social economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

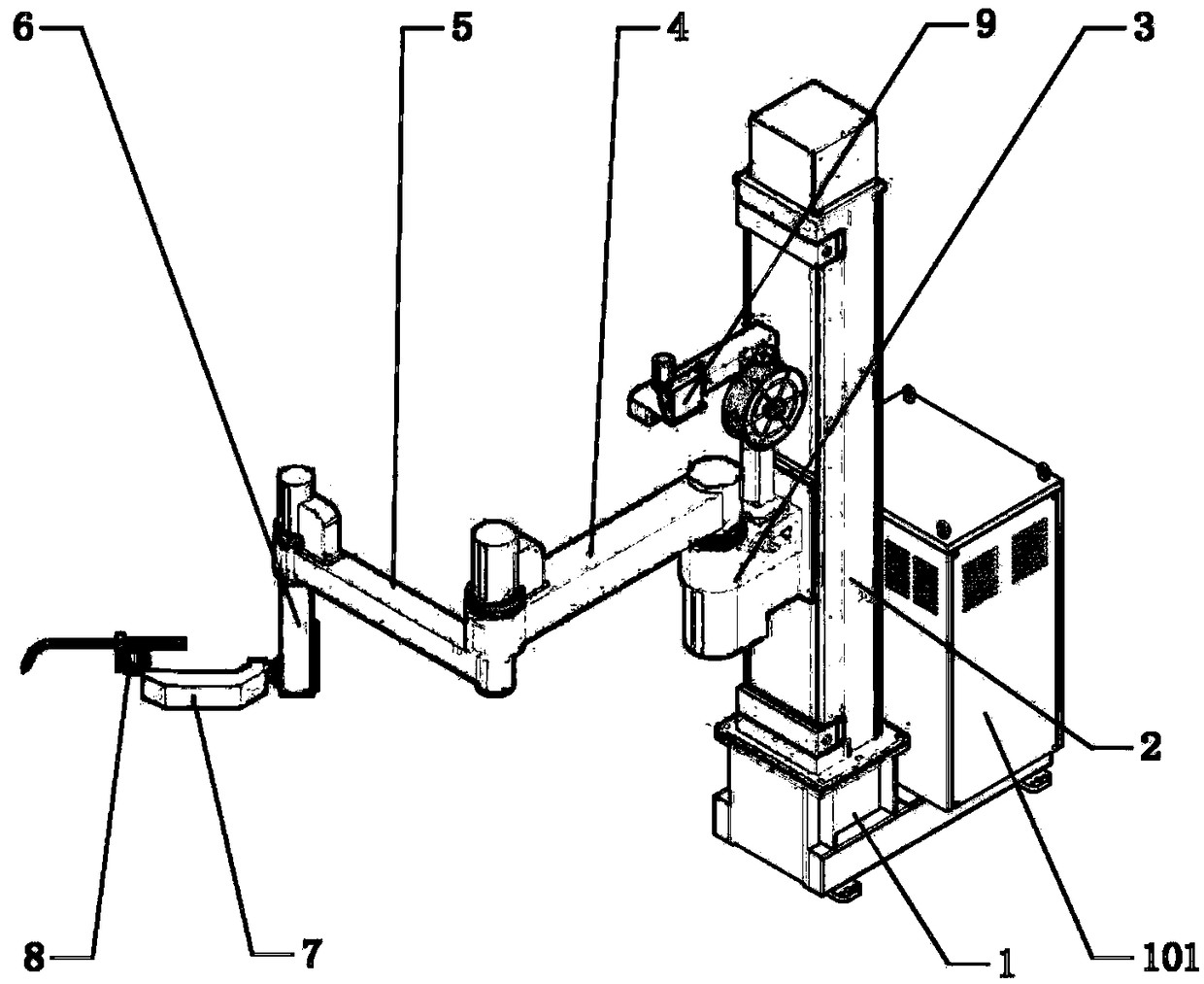

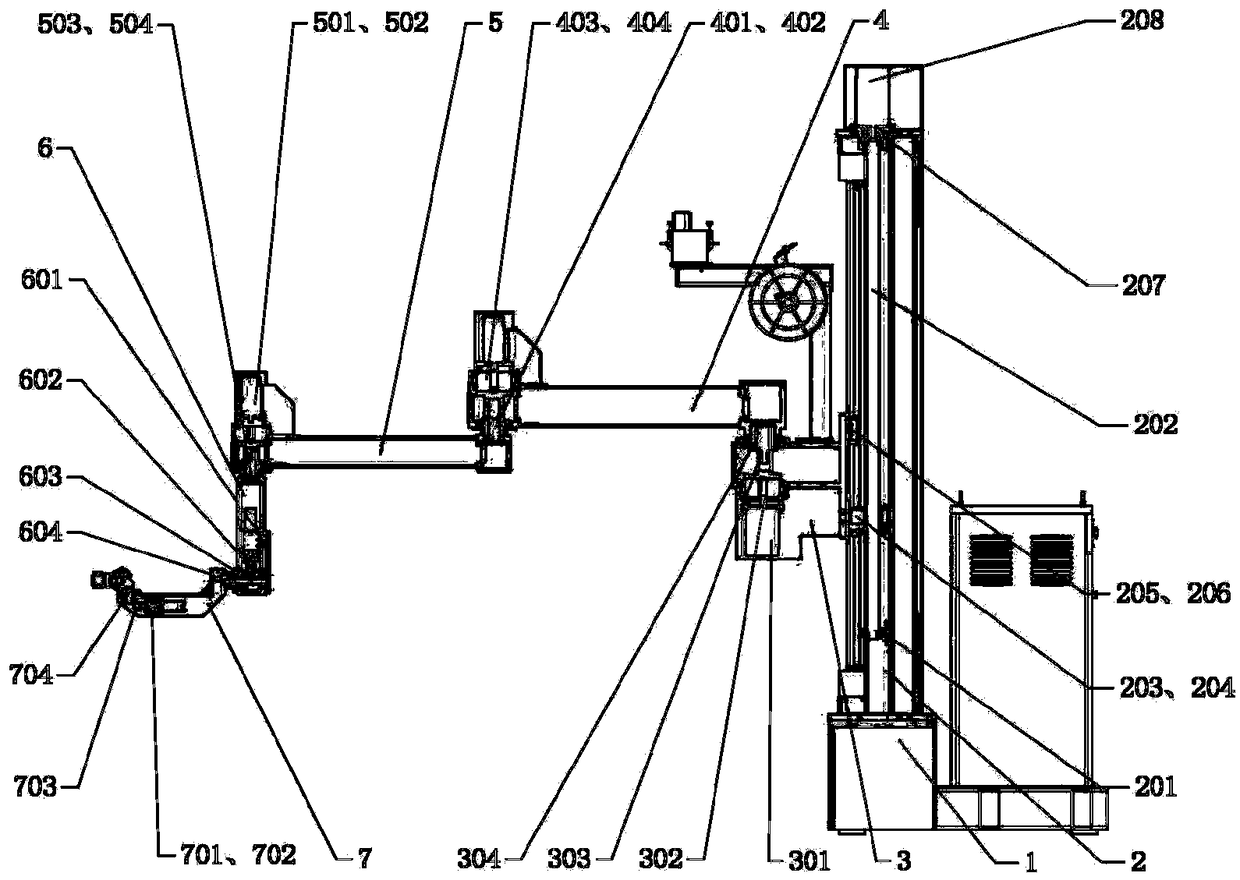

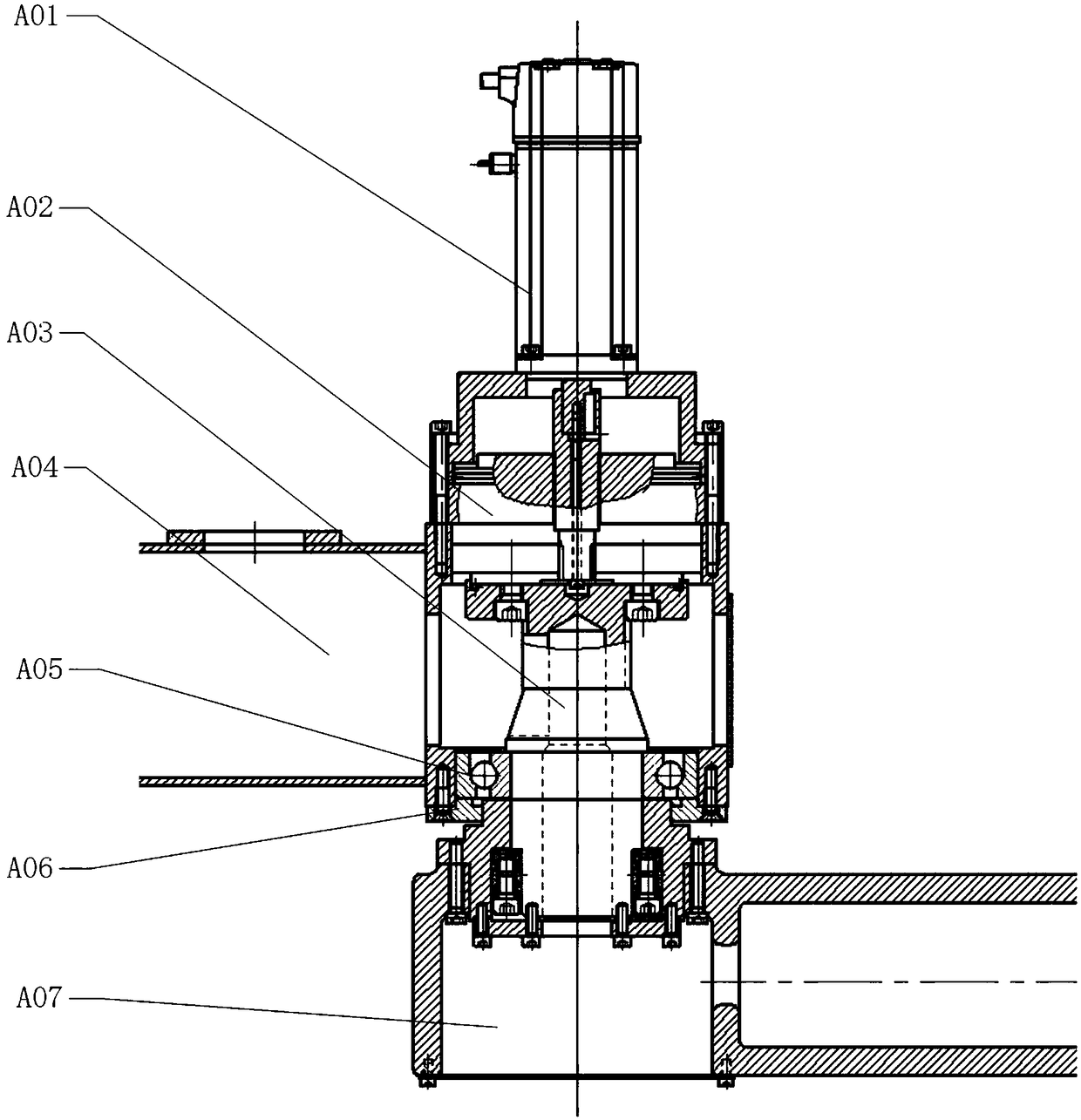

[0025]This embodiment is aimed at the relatively limited operating space of the existing six-axis articulated industrial welding robot. In the process of posture movement at certain positions, the degree of freedom of the six-axis articulated industrial welding robot decreases, and the application of welding with continuous trajectories in space has certain advantages. Therefore, a six-axis welding robot is proposed. The six-axis welding robot has a large working range of the robot arm and can build a large working space in a small footprint. It is suitable for long straight welds and closed circular welds The seam has application advantages, and is suitable for low dimensional position accuracy and bevel alignment quality; in terms of application characteristics, the attitude angle of the end joint axis is highly intuitive, easy to op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com