Preparation method of metal surface superhydrophobic coating

A super-hydrophobic coating, metal surface technology, used in devices, coatings, special surfaces, etc. for coating liquids on the surface, can solve the problems of high cost, unsuitable for being widely used in daily life metal devices, etc., and achieve production equipment. The effect of simplicity, good hydrophobicity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

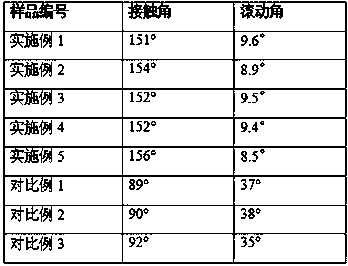

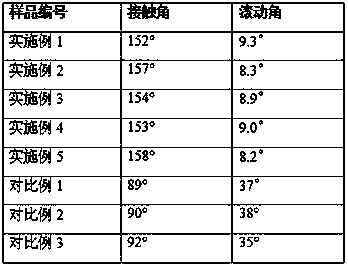

Examples

Embodiment example

[0045] The total mass of the configuration is 500g, wherein the mass fraction of polyvinyl alcohol is 2%, the mass fraction of polyacrylic acid is 5%, the mass fraction of glyoxal is 0.35%, and the hydrophobically modified nano-silica 2% of the average particle size is 30nm. Vinyl alcohol-polyacrylic acid aqueous solution as an example.

[0046] The first step: use a beaker with a mass of m1, take 50g of 50% polyacrylic acid solution, add 350g of water to dilute, stir, add 10g of nano-silica, heat and stir to 95°C;

[0047] Step 2: Slowly add 10g of polyvinyl alcohol, add m2g of water during the process, heat and stir until completely dissolved, stop heating, and let stand to remove air bubbles;

[0048] Step 3: Add 4.4g of 40% glyoxal aqueous solution, weigh the total mass m3 including the beaker, and finally add 500-m3+m1 g water to obtain a solution with a corresponding concentration of each component.

Embodiment 1

[0050] A preparation method of a brass sheet superhydrophobic coating, the selected base material is a 2.5cm * 7.5cm * 0.2cm brass sheet, specifically comprising the following steps:

[0051] 1. Pretreatment: First, use brass sheet metal cleaning agent to ultrasonicate for 10 minutes at 35°C, then rinse the surface with ultrapure water, then immerse the brass sheet substrate in 90°C antirust solution for 45 minutes, and finally take it out , Rinse the surface with ultrapure water, and place it in a dust-free and ventilated condition to air dry naturally. The metal cleaning agent components used are: sodium tripolyphosphate (10 w / %), fatty alcohol polyoxyethylene ether (O-20) (5 w / %), potassium hydroxide (2 w / %) and deionized Water (83 w / %); the antirust solution used is potassium dichromate and chromium trioxide aqueous solution, of which potassium dichromate is 250g / L and chromium trioxide is 0.8g / L.

[0052] 2. After pretreatment, immerse the brass sheet substrate in polyvi...

Embodiment 2

[0055] A preparation method of a brass sheet superhydrophobic coating, the selected base material is a 2.5cm * 7.5cm * 0.2cm brass sheet, specifically comprising the following steps:

[0056] 1. Pretreatment: First, use brass sheet metal cleaning agent to ultrasonicate for 10 minutes at 35°C, then rinse the surface with ultrapure water, then immerse the brass sheet substrate in 90°C antirust solution for 45 minutes, and finally take it out , Rinse the surface with ultrapure water, and place it in a dust-free and ventilated condition to air dry naturally. The metal cleaning agent components used are: sodium tripolyphosphate (8 w / %), fatty alcohol polyoxyethylene ether (O-20) (3 w / %), potassium hydroxide (2 w / %) and deionized Water (87 w / %); the antirust solution used is an aqueous solution of potassium dichromate and chromium trioxide, of which potassium dichromate is 250g / L and chromium trioxide is 0.8g / L.

[0057] 2. After pretreatment, immerse the brass sheet substrate in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com