A kind of preparation method of visible light catalyst with tight connection

A catalyst, visible light technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. and other problems, to achieve the effect of repeated recycling, good sedimentation separation effect, and enhancement of visible light absorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

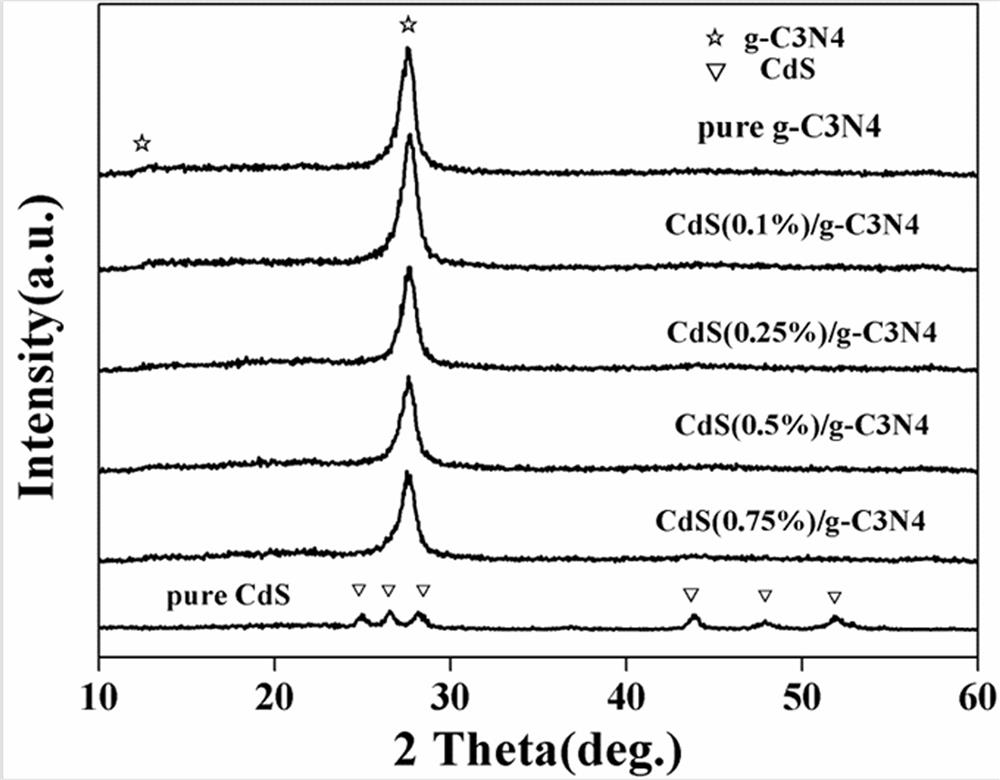

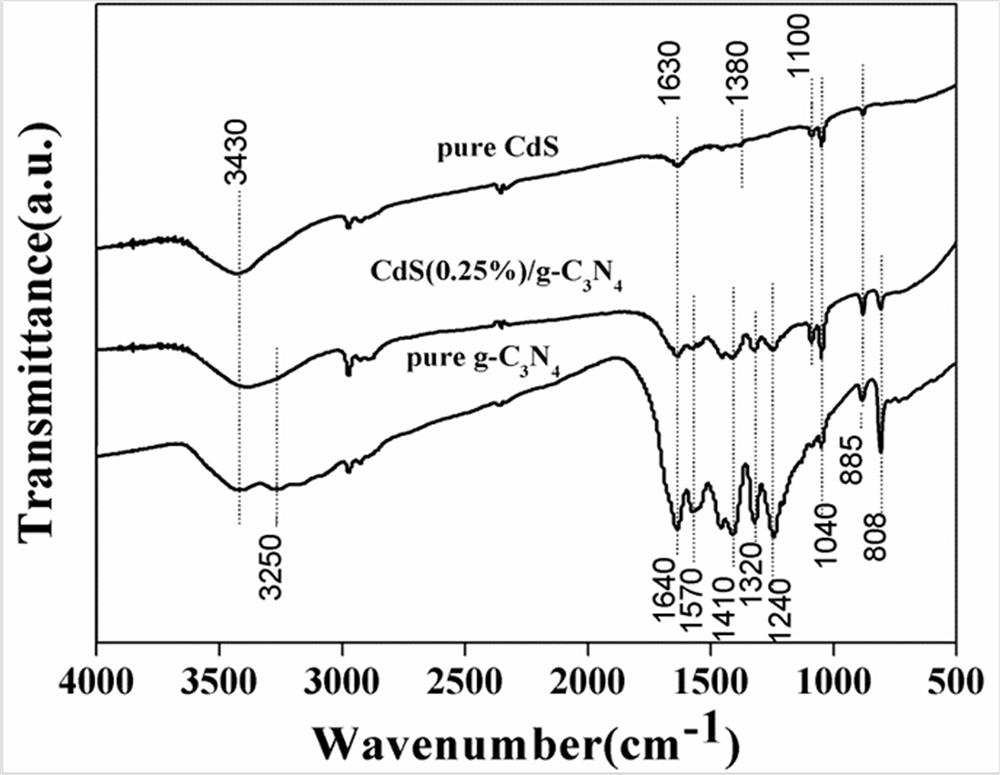

Image

Examples

Embodiment Construction

[0034] A preparation method of a visible light catalyst with tight connection, comprising the steps:

[0035] (1) Preparation of g-C 3 N 4 Nanosheets: Put melamine as a precursor in a crucible with a lid and put it into a muffle furnace; heat it from room temperature to 550 °C at a rapid heating rate of 55 °C / min, and keep it at this temperature for 4 h. After cooling to room temperature, grind to obtain pale yellow powder g-C 3 N 4 Nanosheets, spare;

[0036] (2) Preparation of CdS hollow microspheres:

[0037] Cadmium nitrate tetrahydrate, thiourea and glutathione were added to distilled water in a mass ratio of 1.67:1.24:1 and mixed. After mixing, the mass concentration of thiourea was 0.016 g / ml and stirred for 1 h; then the mixture was transferred to polytetrafluoroethylene In a stainless steel autoclave lined with vinyl fluoride, heated at 250 °C for 3 h; then, the obtained dark yellow product was taken out and centrifuged, washed with ultrapure water for several ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com