Multihole PdRu alloy catalyst for electrochemically synthesizing ammonia and preparation method thereof

A technology of alloy catalyst and gold catalyst, which is applied in the research field of electrochemical synthesis of ammonia, can solve the problems of toxic and harmful substances, unfavorable sustainable development, time-consuming and other problems, and achieve the effect of fast reaction, simple synthesis and high application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method for a porous PdRu alloy catalyst for electrochemical synthesis of ammonia, said method comprising the steps of:

[0042] 1) Prepare 20mM potassium chloropalladate and ruthenium chloride aqueous solutions, then take out 5mL respectively, and mix them to form solution A.

[0043] 2) Configure 20mM sodium borohydride aqueous solution, take out 50mL to make solution B.

[0044] 3) Under stirring, solution B was quickly added dropwise to solution A, reacted for 3 minutes, then centrifuged, washed with ethanol / water five times, and finally dried to obtain a PdRu alloy porous catalyst with good electrocatalytic ammonia synthesis performance.

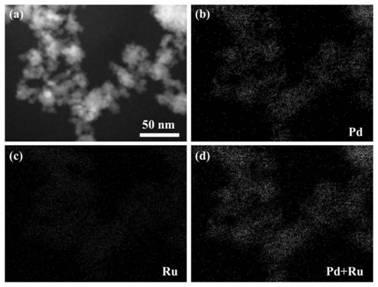

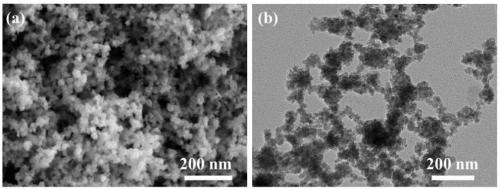

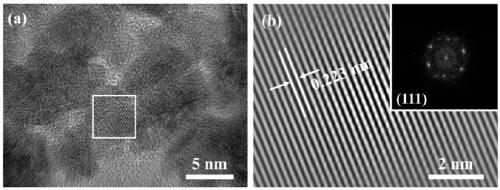

[0045] Obtain the SEM picture of PdRu alloy porous catalyst see figure 1 , to obtain the TEM image of PdRu alloy porous catalyst see figure 2 , to obtain the surface scan of the PdRu alloy porous catalyst see image 3 , to obtain the XRD pattern of the PdRu alloy porous catalyst see Figure 4 , obtain the XPS fi...

Embodiment 2

[0048] A preparation method for a porous PdRu alloy catalyst for electrochemical synthesis of ammonia, said method comprising the steps of:

[0049] 1) Prepare 20mM potassium chloropalladate aqueous solution, and then take out 10mL respectively to make solution A.

[0050] 2) Configure 20mM sodium borohydride aqueous solution, take out 50mL to make solution B.

[0051] 3) Under ultrasonication, solution B was quickly added to solution A, reacted for 3 minutes, then centrifuged, washed with ethanol / water five times, and finally dried to obtain a Pd porous catalyst with good electrocatalytic ammonia synthesis performance.

[0052] Obtain the SEM figure of porous Pd catalyst see Figure 8 , to obtain the XPS diagram of the porous Pd catalyst see Figure 9 , to obtain the electric double layer capacitance map of the porous Pd catalyst see Figure 10 .

[0053] It can be seen from the figure that the Pd catalyst has an obvious porous structure, and the surface is composed of ma...

Embodiment 3

[0055] A method for preparing a porous PdRu alloy catalyst for electrochemical synthesis of ammonia with controllable structure and composition, said method comprising the steps of:

[0056] 1) Prepare 20mM ruthenium chloride aqueous solution, and then take out 10mL respectively to make solution A.

[0057] 2) Configure 20mM sodium borohydride aqueous solution, take out 50mL to make solution B.

[0058] 3) Under ultrasound, solution B was quickly added to solution A, reacted for 3 minutes, then centrifuged, washed with ethanol / water five times, and finally dried to obtain a Ru porous catalyst with good electrocatalytic ammonia synthesis performance.

[0059] Obtain the SEM figure of porous Ru catalyst see Figure 11 , to obtain the XPS diagram of the porous Ru catalyst see Figure 12 , to obtain the electric double layer capacitance map of the porous Ru catalyst see Figure 13 .

[0060] It can be seen from the figure that the Ru catalyst has an obvious porous structure, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com