Production method of infantile goat milk powder

A technology for goat milk powder and infant milk powder, which is applied in the direction of milk preparations, dairy products, and other dairy products, can solve the problems of weight increase, milk powder agglomeration, milk powder waste, etc., to maintain nutritional value, promote brain development, and improve immunity. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

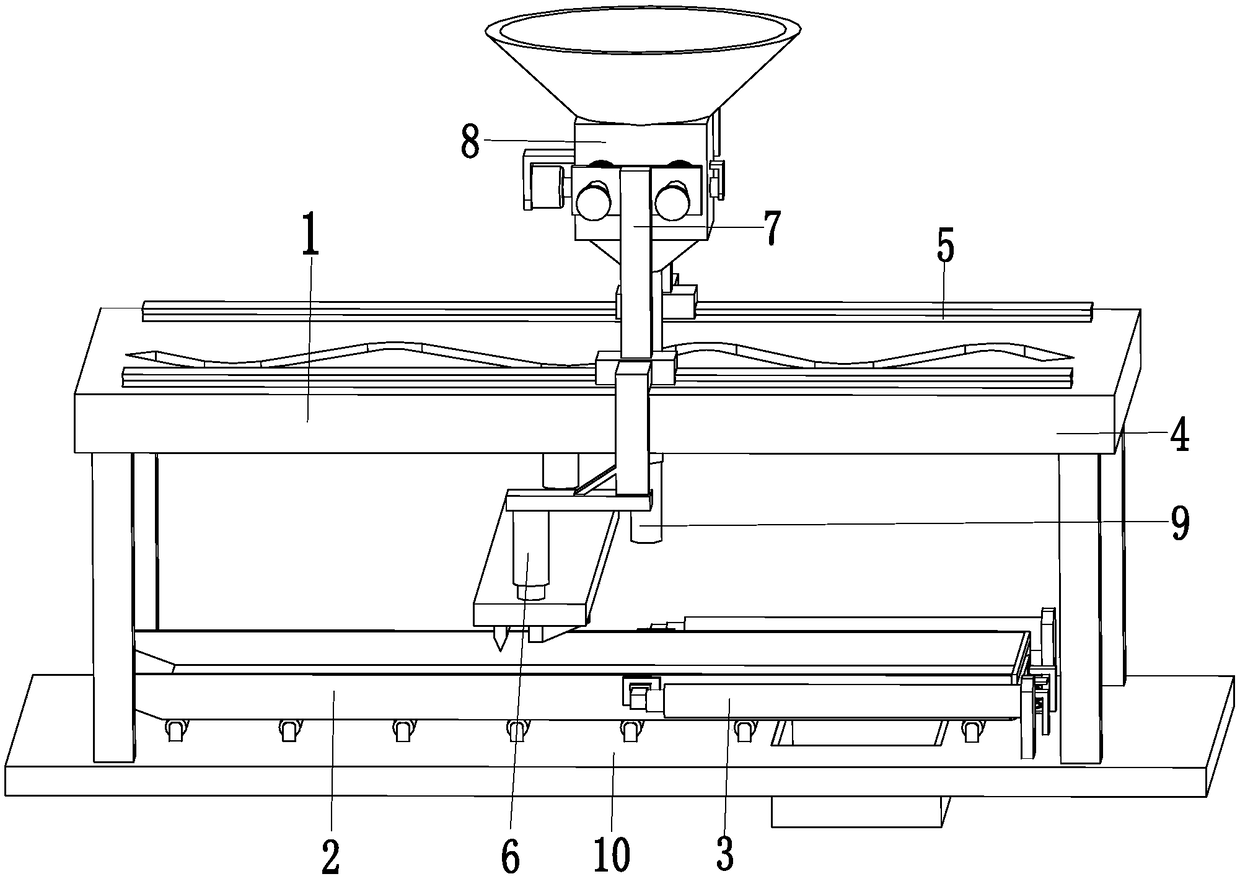

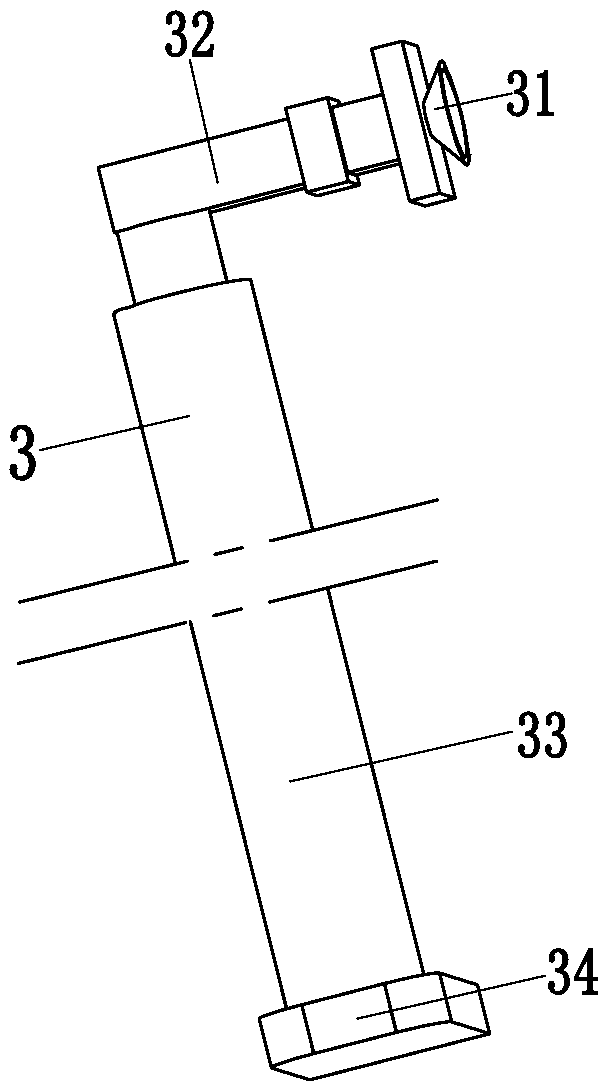

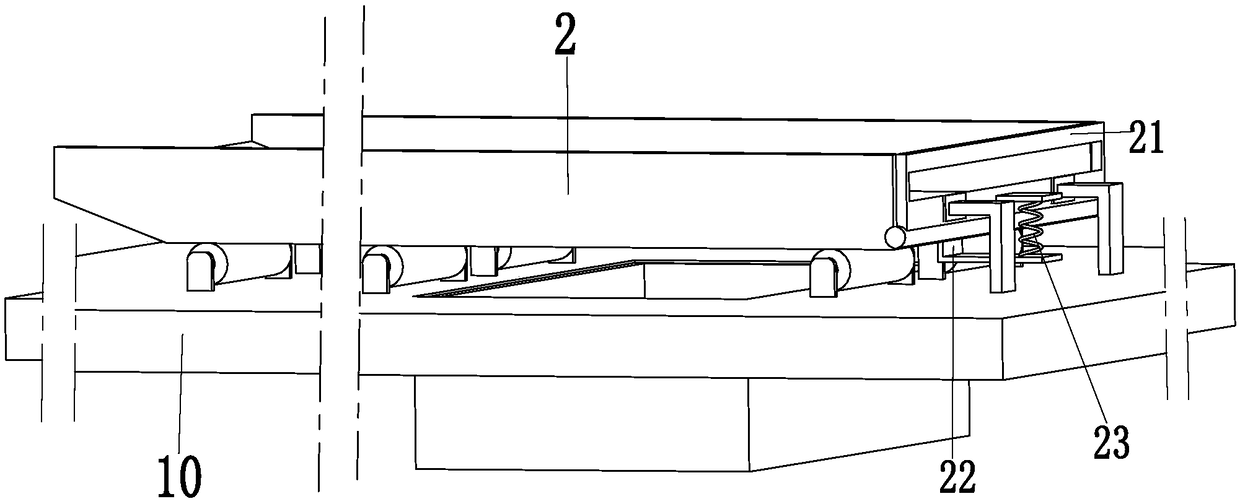

Image

Examples

preparation example Construction

[0045] The invention provides a preparation method of infant formula goat milk powder, comprising the following steps:

[0046] Step S1: The sterilized auxiliary raw goat milk is subjected to membrane separation through an ultrafiltration membrane module to obtain dewhey raw goat milk and goat whey protein; the principle membrane separation technology of the ultrafiltration membrane module can retain the original dairy products. Flavor, as a low temperature technology for dairy products, can save a lot of energy compared to traditional thermal evaporation technology.

[0047] Further, in a preferred embodiment of the present invention, in step S1 of the preparation method, the ultrafiltration membrane assembly includes a first ultrafiltration membrane and a second ultrafiltration membrane, and the membrane material of the first ultrafiltration membrane is ethylene-vinyl alcohol copolymer or vinyl acetate-ethylene copolymer, and the membrane material of the second ultrafiltrati...

Embodiment 1

[0071] This embodiment provides a method for preparing infant goat milk powder. In step S2, the raw materials include: 200 kg of raw goat milk, 500 kg of goat whey protein, 30 kg of lactose, 2.5 kg of vitamins, 0.5 kg of minerals , 220kg complex vegetable oil, 3kg fructooligosaccharide, 66kg galactooligosaccharide, 2kg docosahexaenoic acid, 12kg arachidonic acid, 0.1kg nucleotide, 10kg phospholipid, 4kg immunoglobulin Protein, 12 kg of lactoferrin, 8 kg of milk fat globule membrane, 14 kg of choline, 2 kg of lutein, 10 kg of taurine, 4 kg of casein phosphopeptide and 4.5×108cfu / g probiotics.

[0072] This embodiment specifically includes the following steps:

[0073] Step S1: the sterilized auxiliary raw goat milk is subjected to membrane separation through an ultrafiltration membrane assembly to obtain dewhey raw goat milk and goat whey protein; the ultrafiltration membrane assembly includes a first ultrafiltration membrane and a second ultrafiltration membrane , the membran...

Embodiment 2

[0084] This embodiment provides a method for preparing infant goat milk powder. In step S2, the raw materials include: 450 kilograms of raw goat milk, 350 kilograms of goat whey protein, 100 kilograms of lactose, 0.5 kilograms of vitamins, and 2.5 kilograms of minerals , 100 kg of complex vegetable oil, 33 kg of fructooligosaccharides, 3 kg of galactooligosaccharides, 12 kg of docosahexaenoic acid, 2 kg of arachidonic acid, 0.5 kg of nucleotides, 4 kg of phospholipids, 12 kg of immunoglobulin Protein, 4 kg of lactoferrin, 14 kg of milk fat globule membrane, 6 kg of choline, 8 kg of lutein, 4 kg of taurine, 10 kg of casein phosphopeptide and 3.5×108cfu / g probiotics.

[0085] This embodiment specifically includes the following steps:

[0086] Step S1: the sterilized auxiliary raw goat milk is subjected to membrane separation through an ultrafiltration membrane assembly to obtain dewhey raw goat milk and goat whey protein; the ultrafiltration membrane assembly includes a first ul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com