Life estimation method and device of high-temperature thick-wall pipeline

A technology for life estimation and pipelines, which is applied to measuring devices, using one-time impact force to test the strength of materials, instruments, etc., can solve problems such as long time consumption, and achieve the effect of solving the problem of long time consumption and fast estimation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

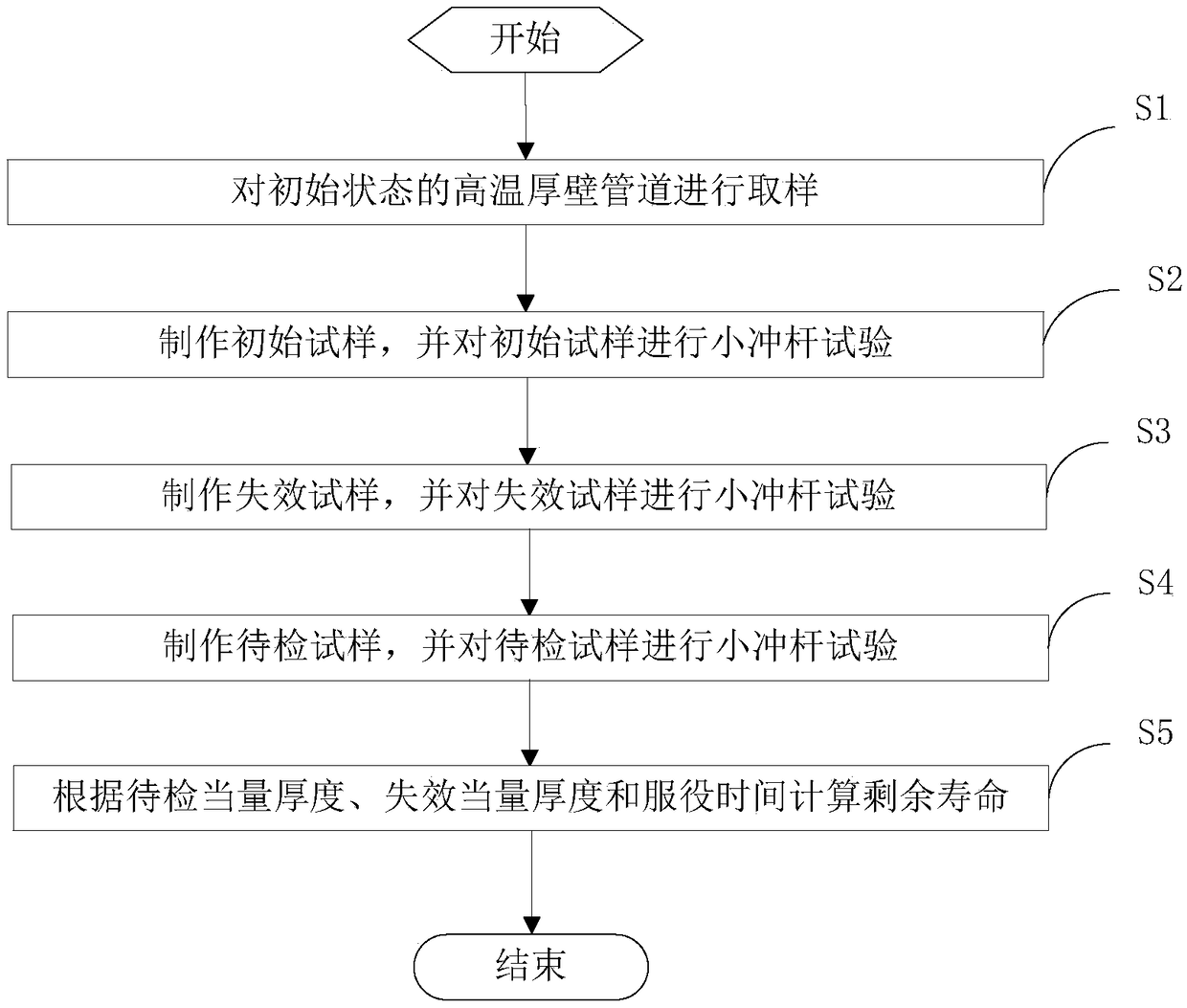

[0049] figure 1 It is a flowchart of a method for estimating the life of a high-temperature thick-walled pipeline provided in an embodiment of the present application.

[0050] Such as figure 1As shown, the life estimation method provided in this embodiment is used to estimate the remaining life of the high-temperature thick-walled pipeline in the power station, and the life estimation method specifically includes the following steps:

[0051] S1. Sampling the high-temperature thick-walled pipeline in the initial state.

[0052] The sampling of the high-temperature thick-walled pipeline can be carried out before the pipeline is put into operation, or the current state can be taken as the initial state. A small sample is obtained by sampling as a pipe sample, which is used to make the initial test piece and the failure test piece. Due to less sampling, it will not have any impact on the structure, strength and life of high-temperature thick-walled pipelines.

[0053] S2. Ma...

Embodiment 2

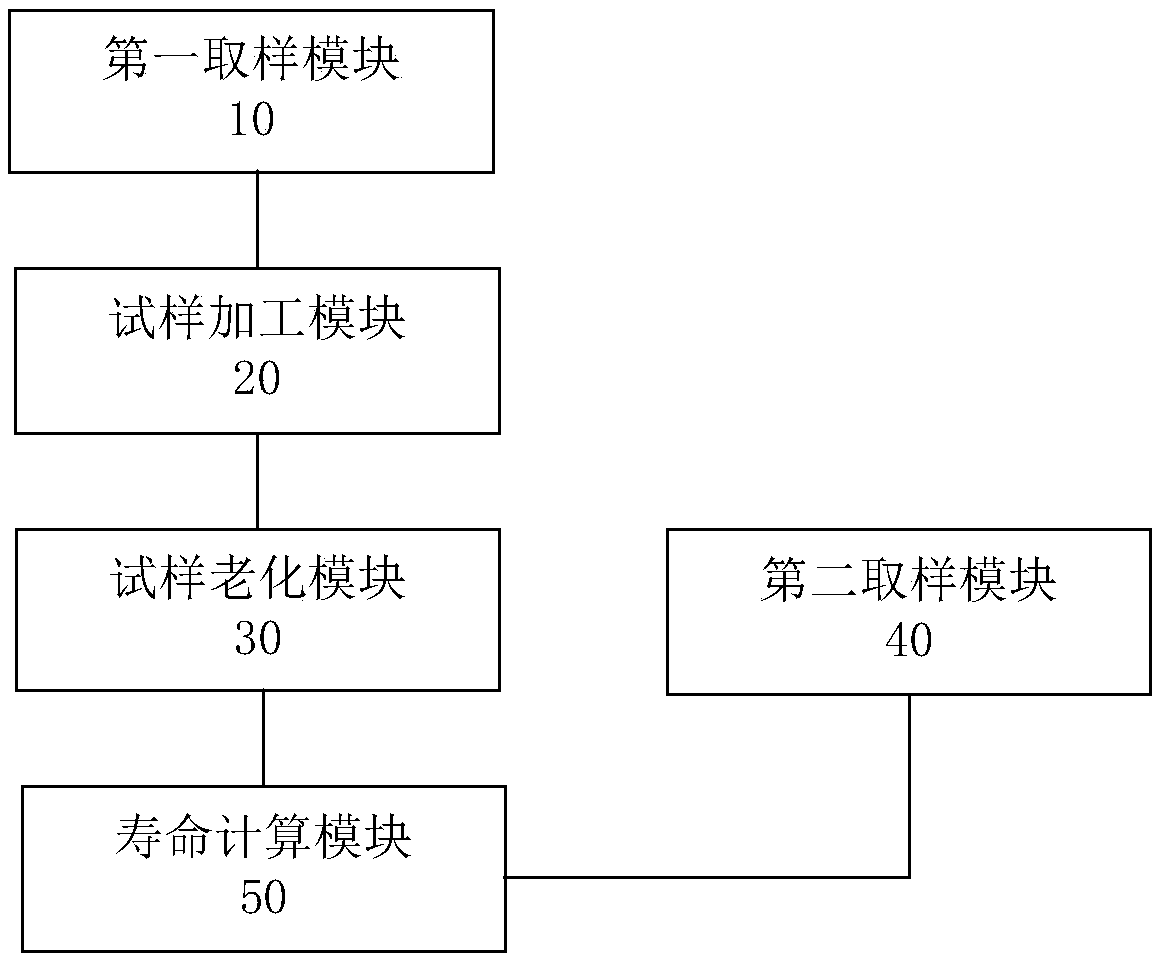

[0088] image 3 A block diagram of a life estimation device for a high-temperature thick-walled pipeline provided in an embodiment of the present application.

[0089] Such as image 3 As shown, the life estimating device provided in this embodiment is used to estimate the remaining life of the high-temperature thick-walled pipeline in a power station. The life estimating device specifically includes a first sampling module 10, a sample processing module 20, a sample aging module 30, The second sampling module 40 and the life calculation module 50 .

[0090] The first sampling module is used for sampling the high-temperature thick-walled pipeline in an initial state.

[0091] The sampling of the high-temperature thick-walled pipeline can be carried out before the pipeline is put into operation, or the current state can be taken as the initial state. A small sample is obtained by sampling as a pipe sample, which is used to make the initial test piece and the failure test pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com