Cleaning agent for cleaning dirt after stripping electroplated layer of glass, cleaning method and electronic product

A technology of cleaning agent and electroplating layer, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, cleaning flexible objects, etc., and can solve the problems of the environment and workers, failure to meet yield requirements, and volatile corrosive gases. , to achieve the effects of little damage to the environment and personnel, promotion of continuous dissolution, and clean appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

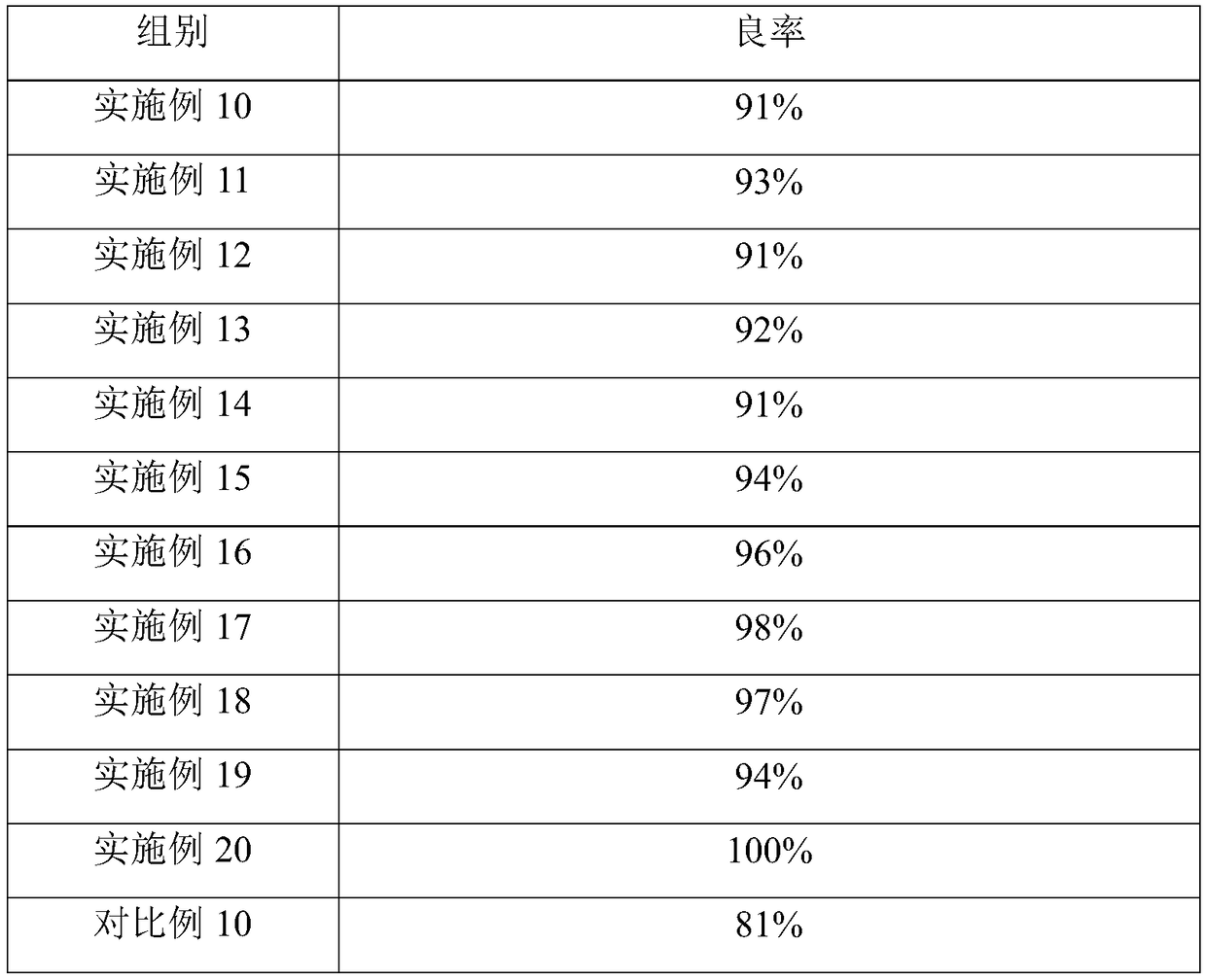

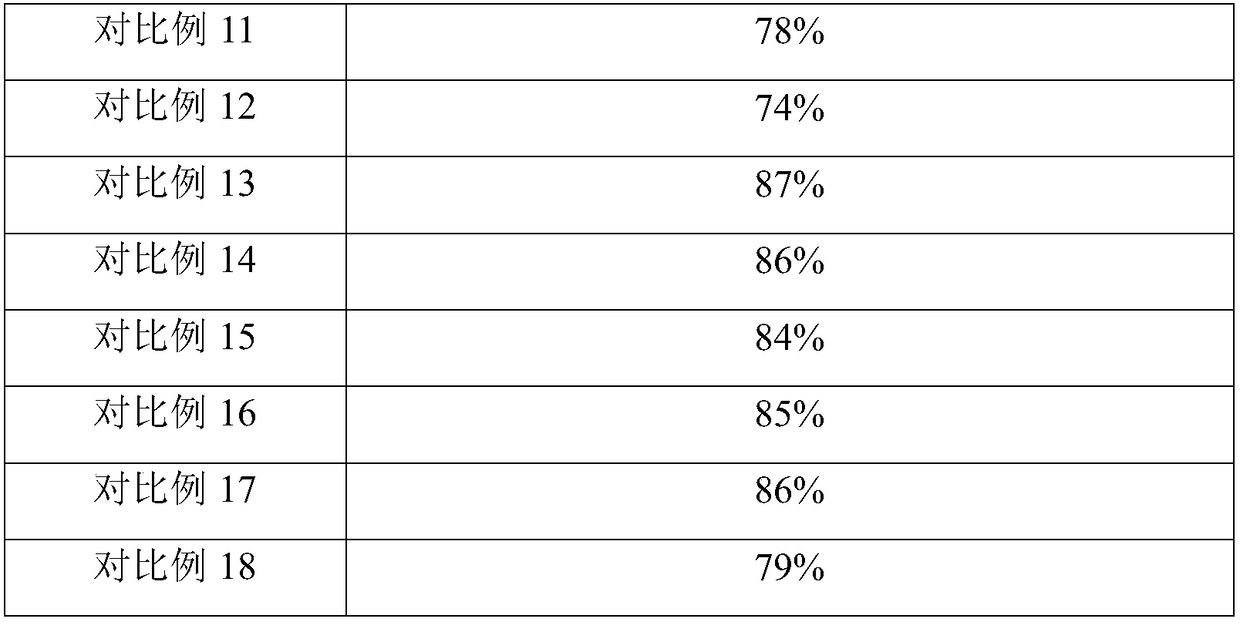

[0054] As a preferred embodiment, the cleaning agent comprises the following components by mass percentage: 5-8% of salicylic acid or its derivatives, 12-14% of sulfamic acid or its derivatives, 6-10% of an oxidizing agent, 0.5-1% of complexing agent, 1-3% of penetrant and the balance of water.

[0055] As a further preferred embodiment, the cleaning agent includes the following components by mass percentage: 5-6% of salicylic acid or its derivatives, 12-13% of sulfamic acid or its derivatives, 6-8% of an oxidant, Mixture 0.5-0.8%, penetrant 2-3% and balance water.

[0056] By further optimizing the concentration ratio of each component, the cleaning and decontamination effect is better.

[0057] In a preferred embodiment, the oxidizing agent is a persulfate, preferably ammonium persulfate.

[0058] In a preferred embodiment, the complexing agent is an aminocarboxylate, including sodium nitrilotriacetate (NTA), ethylenediaminetetraacetate (disodium or tetrasodium EDTA) or di...

Embodiment 1

[0103] A cleaning agent for cleaning the dirt after the glass is de-plated and electroplated, which is composed of the following components according to the mass percentage: 6% of salicylic acid, 12% of N-methyl sulfamic acid, and 8% of ammonium perchlorate , sodium pyrophosphate 0.5%, osmotic agent JFC 3% and water 70.5%.

Embodiment 2

[0105] A cleaning agent for cleaning the dirt after glass stripping electroplating layer is composed of the following components by mass percentage: salicylic acid 4%, sulfamic acid 15%, ammonium hypochlorite 5%, ethylenediamine Disodium tetraacetate 1%, osmotic agent JFC 1% and water 74%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com