Preparation method of lignin having good melting property

A lignin and performance technology, applied in the field of lignin processing, can solve the problems of poor melting performance and achieve the effects of short time consumption, excellent melting performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Mix and stir 560g black liquor powder with appropriate amount of water to form a solution with a concentration of about 18%. After stirring evenly, filter with qualitative filter paper with a pore size of 10-15 μm to remove insoluble matter in the black liquor. Take the filtered filtrate and add hydrochloric acid with a concentration of 6mol / L several times until the pH value of the solution is adjusted to about 2.5, stir with a magnetic stirrer for 30min, and then filter the solution with a qualitative filter paper with a pore size of 10-15 μm. The precipitate was taken out and vacuum-dried, and the sample was completely dried and then ground and passed through a 150-mesh sieve to obtain coniferous wood lignin powder.

[0032] The coniferous wood chips and polyethylene glycol were mixed in a mass ratio of 1:2, the heating temperature was 140° C., and the heating time was 2 hours. After the heat treatment, pour the black liquor in the heated product into pure water, sti...

Embodiment 2

[0036] The softwood lignin powder was prepared by the method in Example 1. The coniferous wood chips and polyethylene glycol were mixed at a mass ratio of 1:3, the heating temperature was 160° C., and the heating time was 2 hours. After the heat treatment, pour the black liquor in the heated product into pure water, stir with a magnetic stirrer, the rotation speed of the magnetic rotor is 200 rpm, and the stirring time is 1h; the liquid after stirring is filtered with filter paper, the The pore size is 2μm-14μm. After drying, polyethylene glycol lignin is obtained.

[0037] Coniferous wood lignin and polyethylene glycol lignin were uniformly mixed at a ratio of 5:1 at a temperature of 50° C. to obtain fusible coniferous wood lignin powder.

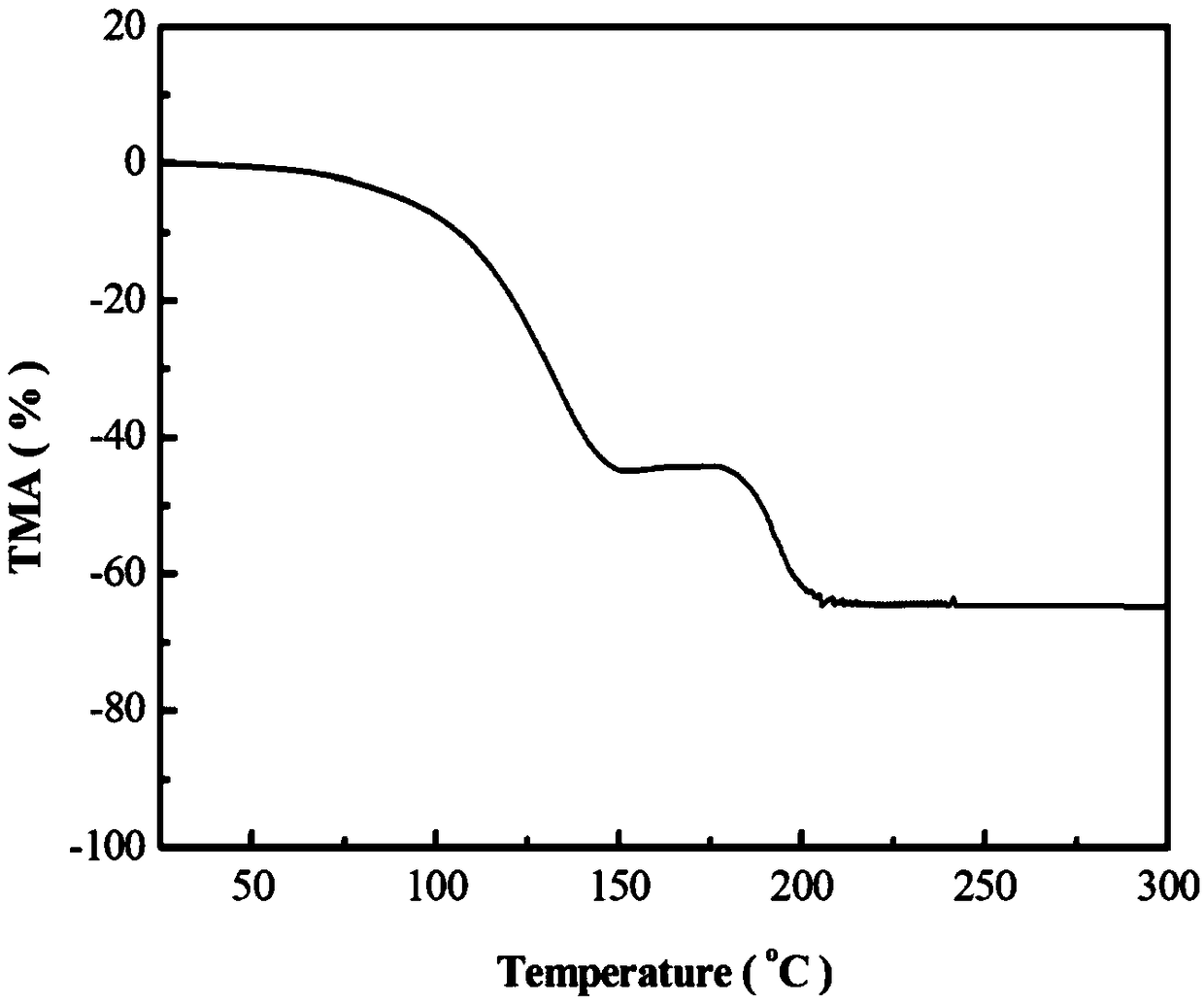

[0038] TMA-4000S System (MAC Science System 010) thermomechanical analyzer was used to measure the thermomechanical behavior of softwood lignin after treatment, see figure 2 . The curve has a glass transition temperature as well as a ...

Embodiment 3

[0040]The softwood lignin powder was prepared by the method in Example 1. The coniferous wood chips and polyethylene glycol were mixed in a mass ratio of 1:4, the heating temperature was 160° C., and the heating time was 1 h. After the heat treatment, pour the black liquor in the heated product into pure water, stir with a magnetic stirrer, the rotation speed of the magnetic rotor is 200 rpm, and the stirring time is 2h; the liquid after stirring is filtered with filter paper, and the The pore size is 2μm-14μm. After drying, polyethylene glycol lignin is obtained.

[0041] Coniferous wood lignin and polyethylene glycol lignin were uniformly mixed at a ratio of 4:1 at a temperature of 70° C. to obtain fusible coniferous wood lignin powder.

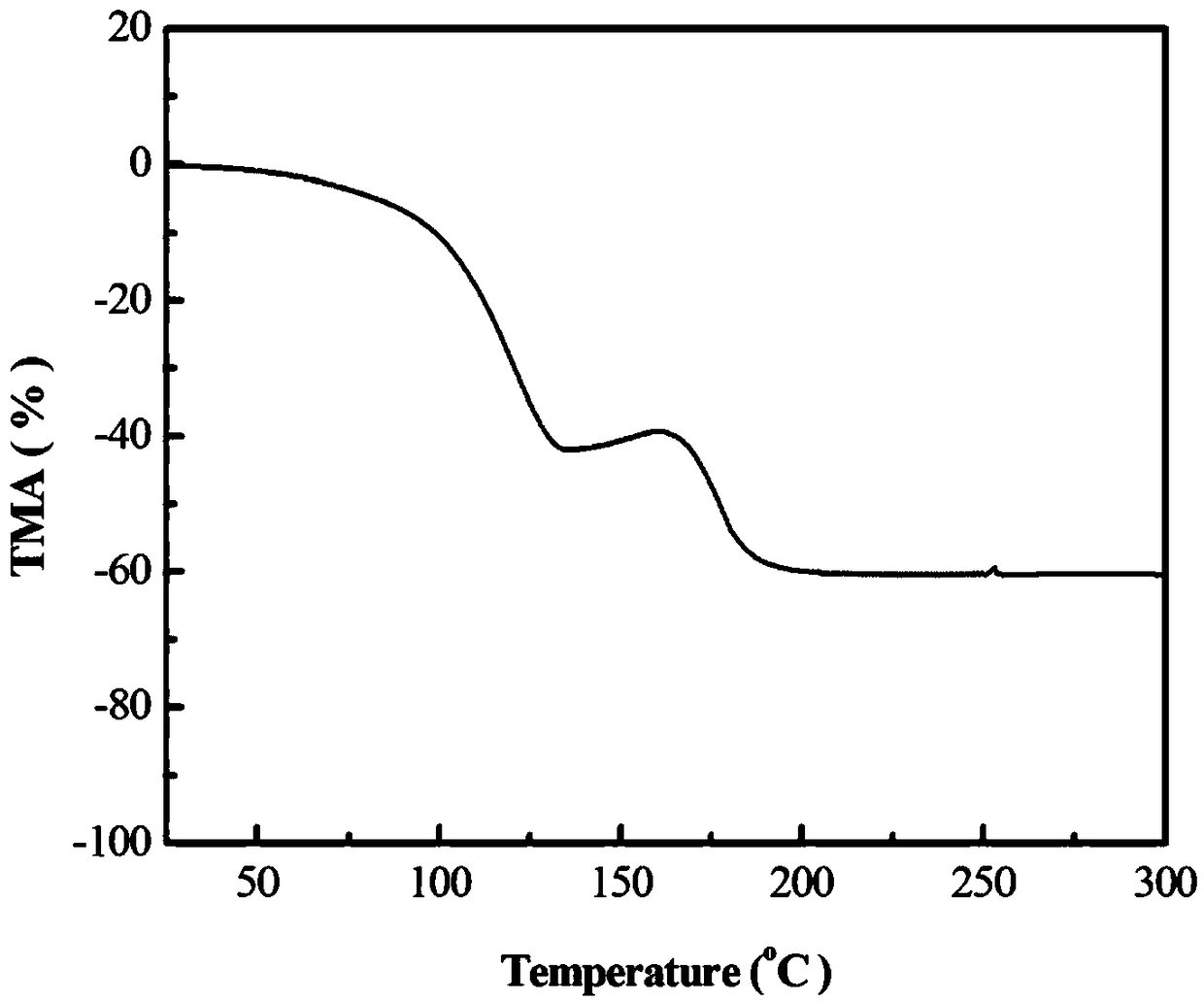

[0042] TMA-4000S System (MAC Science System 010) thermomechanical analyzer was used to measure the thermomechanical behavior of softwood lignin after treatment, see image 3 . The curve has a glass transition temperature as well as a he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com