Foam extinguishing agent and preparation method and application thereof

A foam fire extinguishing agent and foaming agent technology, which is applied in fire protection equipment and other directions, can solve the problems of high bioaccumulation, multiple toxicity and environmental toxicity hazards, and achieve the effects of good melting performance, easy operation and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

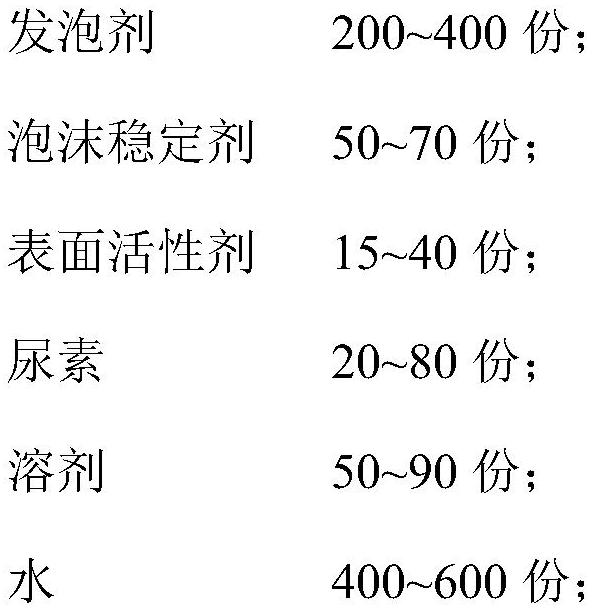

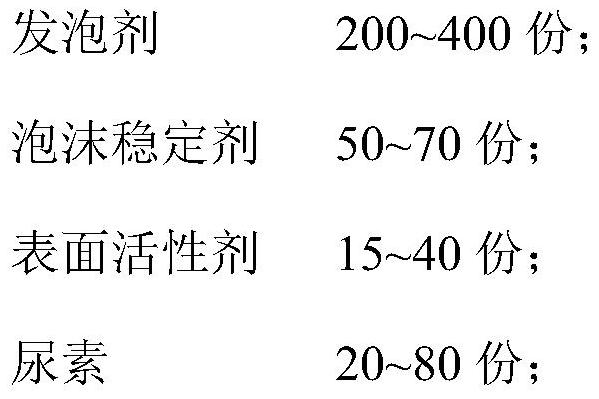

Method used

Image

Examples

Embodiment 1

[0048] The present embodiment has prepared a foam fire extinguishing agent, and the consumption of each component is shown in Table 1, and the specific process is:

[0049] 1) Preparation of anti-burning agent: slowly adding the fluorosurfactant into the anti-burning agent preparation cylinder equipped with alkyl glucoside, stirring to obtain the anti-burning agent after 30 minutes, and standing for standby;

[0050] 2) inject deionized water into the stirring cylinder, add sodium lauryl sulfate, urea, butyl glycol ether and stir for 30 minutes;

[0051] 3) Add the anti-burning agent to the stirring tank, stir for 30 minutes, then add glycerin, stir for 20 minutes, and let it stand to obtain a foam fire extinguishing agent.

Embodiment 2

[0053] The present embodiment has prepared a foam fire extinguishing agent, and the consumption of each component is shown in Table 1, and the specific process is:

[0054] 1) Preparation of anti-burning agent: slowly adding the fluorosurfactant into the anti-burning agent preparation cylinder equipped with alkyl glucoside, stirring to obtain the anti-burning agent after 30 minutes, and standing for standby;

[0055] 2) inject deionized water into the stirring cylinder, add sodium lauryl sulfate, urea, butyl glycol ether and stir for 30 minutes;

[0056] 3) Add the anti-burning agent to the stirring tank, stir for 30 minutes, then add ethylene glycol, stir for 20 minutes, and let it stand to obtain a foam fire extinguishing agent.

Embodiment 3~4

[0058] The present embodiment has prepared a foam fire extinguishing agent, and the consumption of each component is shown in Table 1, and the specific process is:

[0059]1) Preparation of anti-burning agent: slowly add the fluorosurfactant into the anti-burning agent preparation cylinder equipped with sodium lauryl sulfate, stir to obtain the anti-burning agent after 30 minutes, and let stand for later use;

[0060] 2) inject deionized water into the stirring tank, add propyl betaine, urea, butyl glycol ether and stir for 30 minutes;

[0061] 3) Add the anti-burning agent to the stirring tank, stir for 30 minutes, then add ethylene glycol, stir for 20 minutes, and let it stand to obtain a foam fire extinguishing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com