A kind of ceramic glaze with starlight effect and its preparation method and application method

A ceramic glaze and starlight technology, applied in the field of ceramic glaze, can solve the problems of poor starlight effect, poor antifouling performance, good starlight effect, etc., to reduce glaze defects, reduce opening pinholes, and improve antifouling performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

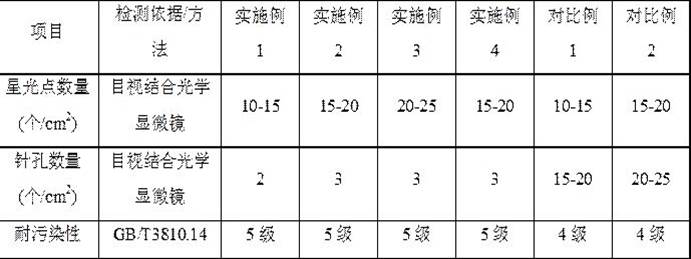

Examples

Embodiment 1

[0042] A ceramic glaze with a starlight effect in this embodiment is prepared by mixing a suspension of starlight particles with a weight percentage of 15% and a transparent glaze slurry with a weight percentage of 85%.

[0043] Among them, the weight percentage of each raw material in the starlight particle suspension is: 30% of quartz sand, 15% of zircon sand, 5% of ethylene glycol, 7% of glycerin, 40% of water, 2.5% of organic bentonite, sodium carboxymethyl cellulose 0.4% and fumed silica 0.1%.

[0044] The quartz sand is white quartz sand with a fineness of 80-120 mesh, and the SiO in the white quartz sand 2 The content is not less than 99.5%. The fineness of the zircon sand is 60-80 mesh, and the ZrO in the zircon sand 2The content is not less than 66%; before preparing the starlight particle suspension, the zircon sand needs to be calcined at at least 900°C for 3 hours or more to remove black impurities that affect its appearance.

[0045] Among them, the transparent...

Embodiment 2

[0060] A ceramic glaze with a starlight effect in this embodiment is prepared by mixing a suspension of starlight particles with a weight percentage of 28% and a transparent glaze slurry with a weight percentage of 72%.

[0061] Among them, the weight percent of each raw material in the starlight particle suspension is: 25% of quartz sand, 10% of zircon sand, 5% of ethylene glycol, 5% of glycerin, 50% of water, 4% of organic bentonite, sodium carboxymethyl cellulose 0.8% and fumed silica 0.2%.

[0062] The specific selection of the quartz sand and zircon sand refers to Example 1.

[0063] Wherein, the raw material formula of transparent glaze slurry refers to embodiment 1.

[0064] The weight percent of each raw material in the transparent glaze of this transparent glaze slurry is: potassium feldspar 30%, albite 29%, calcined kaolin 6%, calcite 18%, strontium carbonate 8%, quartz 4%, calcined talc 3% and Calcined zinc oxide 2%.

[0065] For the preparation method of a ceram...

Embodiment 3

[0072] A ceramic glaze with a starlight effect in this embodiment is prepared by mixing a suspension of starlight particles with a weight percentage of 33% and a transparent glaze slurry with a weight percentage of 67%.

[0073] Among them, the weight percent of each raw material in the starlight particle suspension is: 35% quartz sand, 15% zircon sand, 2% ethylene glycol, 3% glycerin, 39.7% water, 4% organic bentonite, sodium carboxymethyl cellulose 1% and fumed silica 0.3%.

[0074] The specific selection of the quartz sand and zircon sand refers to Example 1.

[0075] Wherein, the raw material formula of transparent glaze slurry refers to embodiment 1.

[0076] The percentage by weight of each raw material in the transparent glaze of this transparent glaze slurry is: potassium feldspar 30%, albite feldspar 20%, calcined kaolin 6%, calcite 25%, strontium carbonate 9%, quartz 4%, calcined talc 3% and Calcined zinc oxide 3%.

[0077] For the preparation method of a ceramic ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com