High-toughness and weather-resistant fiber reinforced plastic photovoltaic scaffold

A photovoltaic support, high toughness and weather resistance technology, applied in the field of FRP photovoltaic support, can solve problems such as cracks, inconvenient transportation and installation, heavy steel weight, etc., and achieve good compatibility and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

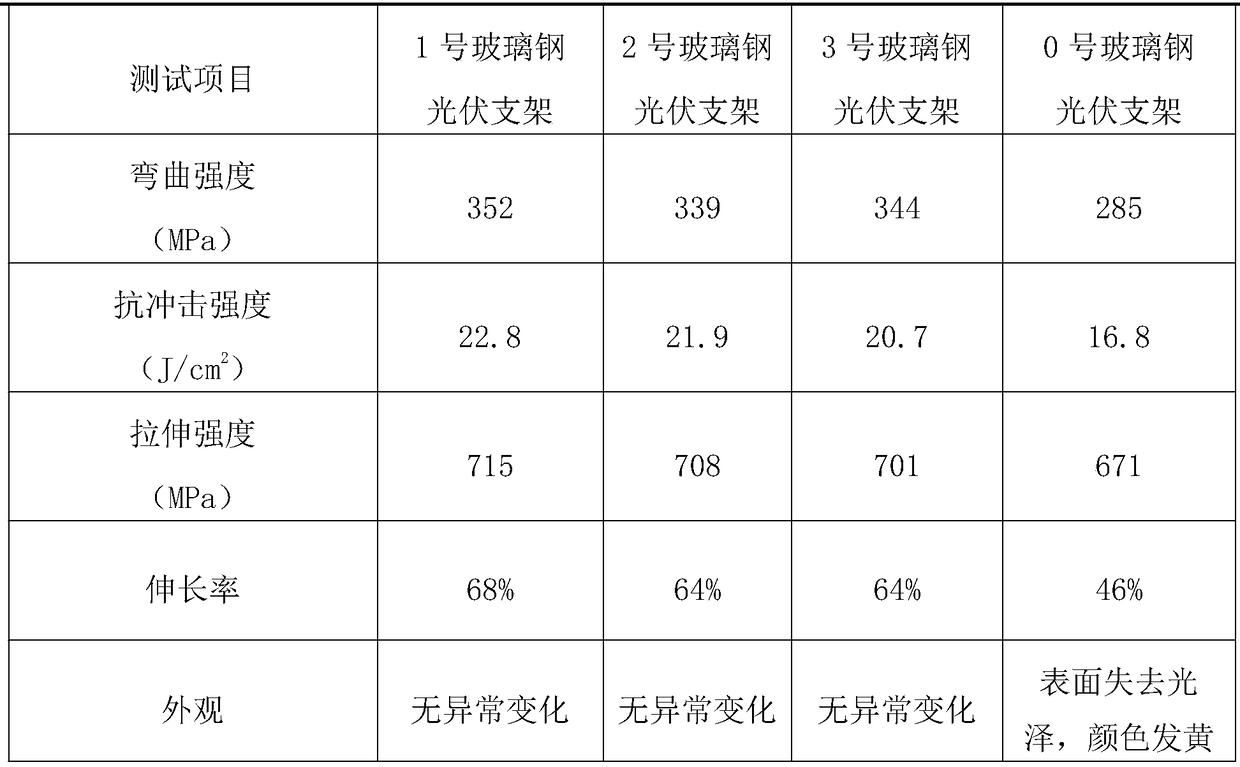

Examples

Embodiment 1 2

[0020] The preparation of embodiment 1 titanium dioxide modified attapulgite

[0021] 1) Disperse attapulgite with a mesh number of 800-1000 into 38 wt% hydrochloric acid solution under ultrasonic conditions, reflux in a water bath at 100°C for 16 hours, filter, wash until neutral and dry to obtain purified attapulgite for later use;

[0022] 2) Stir 100 g of the purified attapulgite evenly, then add 1 L of tetrabutyl titanate, 12 L of ethanol, 10 L of acetylacetone, and 12 L of deionized water, stir and react at room temperature to obtain a sol and then turn it into a gel. The obtained gel is dried and then calcined and ground to obtain a titanium dioxide-attapulgite composite;

[0023] 3) Add 10 g of silicone oil to the obtained titanium dioxide-attapulgite composite by spraying, stir evenly, then add 5 g of silane coupling agent under high-speed stirring at 1500-2000 r / min, and mix evenly.

Embodiment 2

[0025] A high-toughness and weather-resistant glass fiber reinforced plastic photovoltaic bracket, which is composed of the following raw materials in parts by weight: 100 parts of epoxy resin E44, 1 part of dibenzoyl peroxide, 1 part of methyl ethyl ketone peroxide, 2.5 parts of zinc stearate, and lead stearate 1.5 parts, 20 parts of calcium carbonate, 23 parts of titanium dioxide modified attapulgite.

Embodiment 3

[0027] A high-toughness and weather-resistant glass fiber reinforced plastic photovoltaic bracket, which is composed of the following raw materials in parts by weight: 120 parts of epoxy resin E44, 1 part of dibenzoyl peroxide, 3 parts of methyl ethyl ketone peroxide, 2.5 parts of zinc stearate, and lead stearate 2 parts, calcium carbonate 25 parts, titanium dioxide modified attapulgite 30 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com