Preparation method of porous carbon electrode material for supercapacitor

A technology for supercapacitors and electrode materials, which is applied in the fields of hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, chemical instruments and methods, etc. It can solve the problems of product residual chemicals, high cost of activators, corrosion equipment, etc., and achieve shortening Diffusion distance, catalytic effect improvement, and development-promoting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

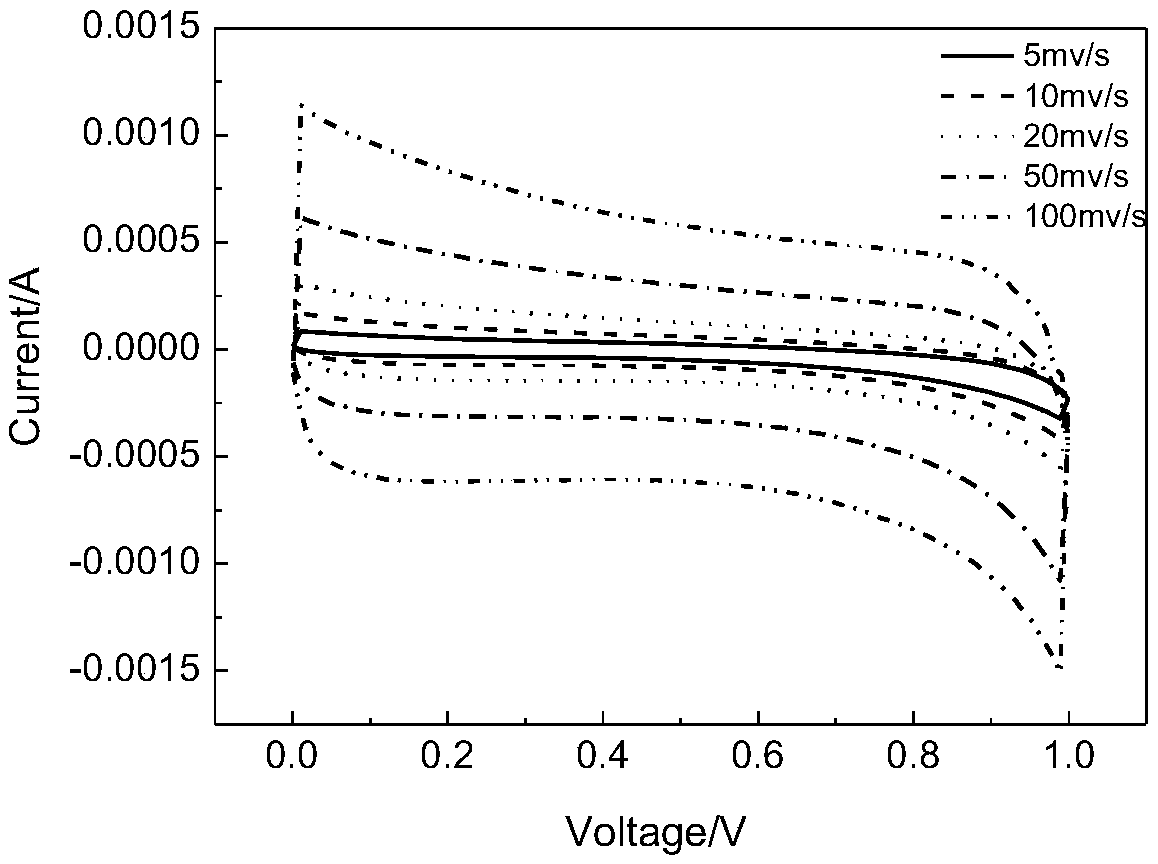

Image

Examples

preparation example Construction

[0022] A method for preparing a porous carbon electrode material for a supercapacitor. The method uses pitch as the main raw material, adds a pore-forming agent and a catalyst, and sequentially undergoes a mixing process, an air oxidation stabilization process, a carbonization process, and a water vapor activation process to obtain a high specific carbon electrode material. Surface area porous carbon material; comprising the steps of:

[0023] 1) Add the raw asphalt into the pore-forming agent or add the catalyst at the same time, put it in the autoclave, 2 Under pressure protection, stir at 130-160°C for 0.5-1.5 hours to obtain mixed asphalt.

[0024] 2) Crush the mixed asphalt obtained in step 1), sieve it with 0.154mm and 1mm sieves, and take intermediate particle size asphalt for air oxidation stabilization, with an air flow rate of 60-100L / h and a heating rate of 0.3-1°C / min Raise the temperature to 250-300°C, hold the temperature for 3-8 hours, and obtain an air oxidati...

Embodiment 1

[0035] Get a certain quality of coal tar pitch and 15wt% naphthalene, mix them evenly, place them in an autoclave, 2Under pressure protection, stir at 150°C for 1 hour to ensure that the asphalt and naphthalene are fully mixed. Crush the mixed asphalt, sieve it with 0.154mm and 1mm sieves, and take asphalt with intermediate particle size for air oxidation stabilization experiment. The air flow rate is 80L / h, and the temperature is raised to 270°C at a rate of 0.5°C / min. Asphalt with certain pores is required. Stabilized asphalt at 0.1L / min N 2 Under the protection of the atmosphere, the temperature was first raised to 415°C at a heating rate of 3°C / min, and then raised to 515°C at a heating rate of 5°C / min to carbonize into coke. Crumble the coke sample through a 0.075mm sieve, take the sample under the sieve, put it in a white steel mesh, move it into the activation furnace, raise the temperature to 400°C at a heating rate of 3°C / min, keep the temperature for 30min, and the...

Embodiment 2

[0038] A certain quality of oxidized pitch was used as raw material, 15wt% naphthalene and 0.5wt% ferrocene were added, placed in an autoclave, and the mixing process and air oxidation stabilization process were carried out using the test parameters of Example 1. Stabilized asphalt at 0.1L / min N 2 Under the protection of the atmosphere, the temperature was first raised to 415°C at a heating rate of 5°C / min, and then the temperature was raised to 515°C at a heating rate of 5°C / min to carbonize into coke. Break the coke sample through a 0.075mm sieve, take the sample under the sieve, put it in a white steel mesh, move it into the activation furnace, raise the temperature to 400°C at a heating rate of 5°C / min, keep the temperature for 30min, and then raise the temperature at a heating rate of 5°C / min to 950°C, when the temperature in the furnace is constant at 900°C, pass water vapor into the activation furnace at a rate of 1mL / min for activation for 1h, and finally cool down to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com