Airway structure in hearth of hard alloy and metal ceramic debinding furnace

A cermet and cemented carbide technology, which is applied in the fields of mechanical processing and powder metallurgy, can solve problems such as unstable properties of cermet substrates, and achieve the effects of uniform carrier gas flow distribution, uniform cooling effect, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

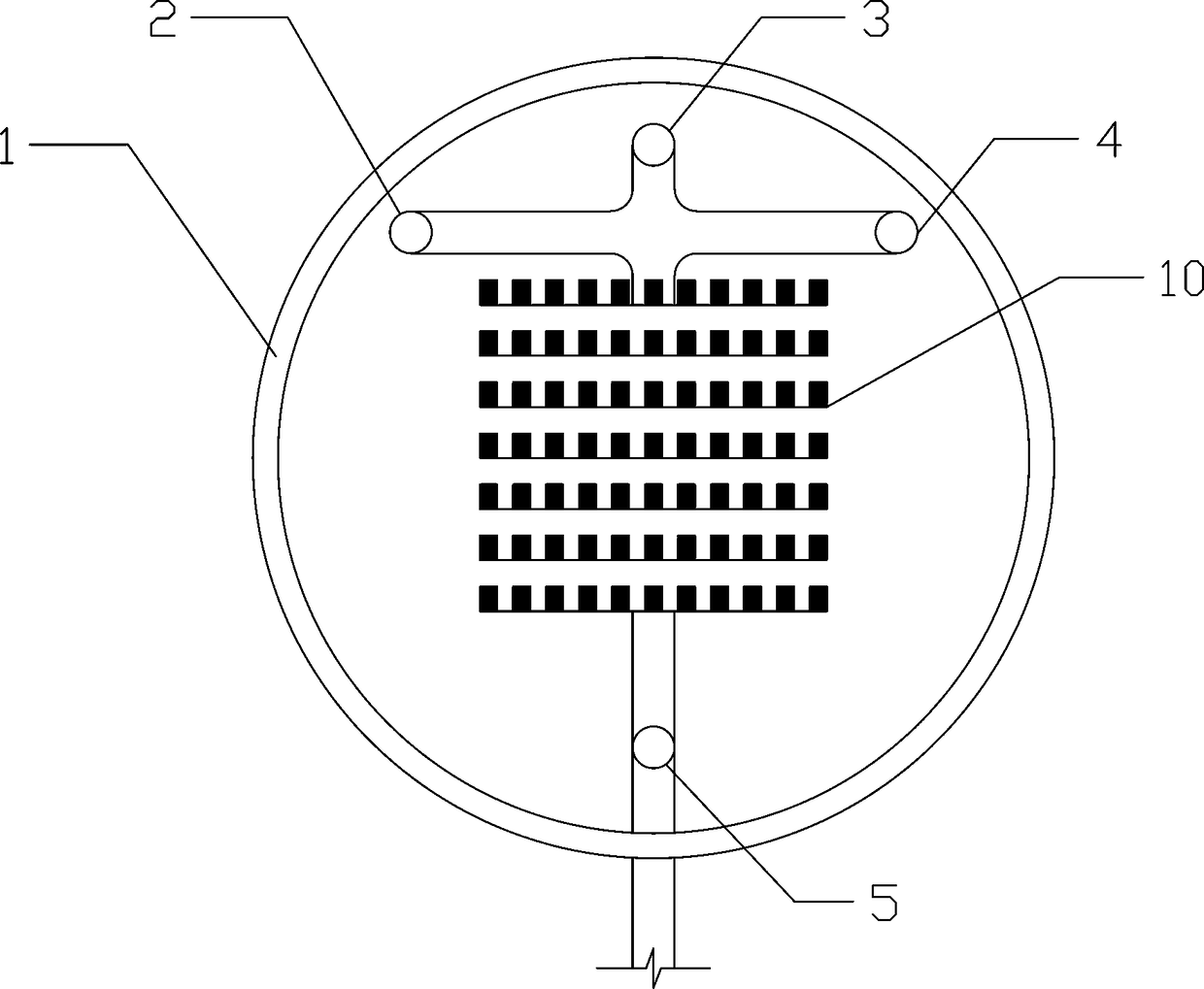

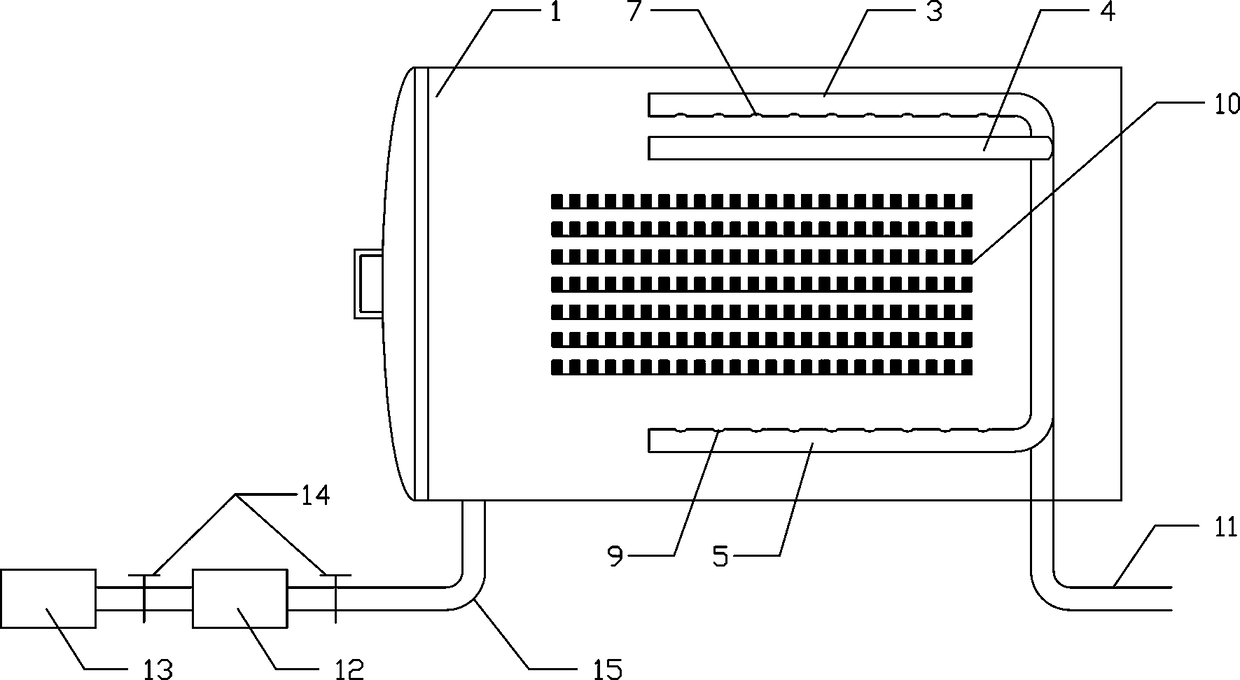

[0028] like Figure 1-7 Among them, a hard alloy and cermet degreasing furnace inner gas passage structure, including an air inlet pipe 11, the air inlet pipe 11 is arranged on the bottom tail end of the furnace hearth 1 upwardly, and the upper end of the air inlet pipe 11 located in the furnace hearth 1 is provided with a first One air guide pipe 2, the second air guide pipe 3 and the third air guide pipe 4, the intake pipe 11 part located in the furnace 1 is provided with a fourth air guide pipe 5 near the bottom of the furnace 1, and the product is placed in the sintering work during degreasing and sintering On the graphite boat layer 10 in the area;

[0029] The first air guide pipe 2, the second air guide pipe 3, the third air guide pipe 4 and the fourth air guide pipe 5 are arranged horizontally along the axial direction of the furnace 1, and the first air guide pipe 2 and the third air guide pipe 4 are respectively arranged on On both sides above the graphite boat laye...

Embodiment 2

[0037] On the basis of Example 1, the carrier gas pressure difference in the first air guide tube 2, the second air guide tube 3, the third air guide tube 4 and the fourth air guide tube 5 is 3-4bar, and the carrier gas filling pressure is 0.3- 0.4bar, the carrier gas pressure in the furnace 1 is maintained at 50-300Pa.

Embodiment 3

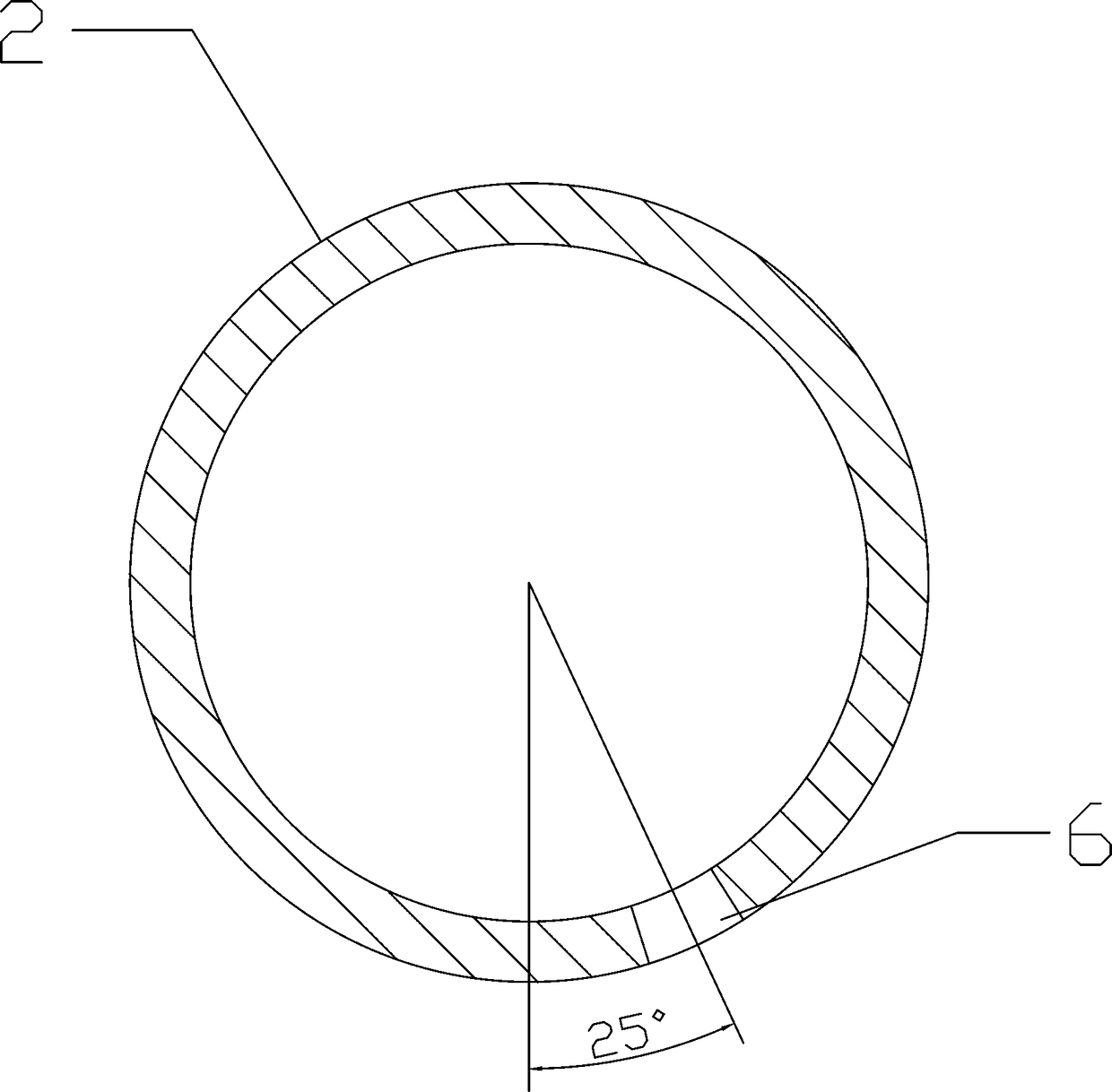

[0039] On the basis of Example 1, the exhaust holes 6 of the first air duct and the exhaust holes 8 of the third air duct are set at 25°-30° to the vertical direction, preferably 25°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com