Preparation method and product of hemp tofu

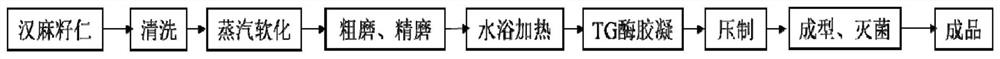

A technology for hemp and tofu is applied in the field of preparation of hemp tofu, and can solve the problems of poor elasticity and hardness of hemp tofu, brittleness, and uneven overall structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation of embodiment 1 hemp tofu

[0045] (1) Pre-swelling: select the mildew-free shelled hemp seeds and wash them to soften with steam. The steam pressure used is 2MPa;

[0046] (2) Refining and slag removal: refine the fully swollen hemp seeds and water at a ratio of 1:5, and pass through 100 meshes to obtain hemp milk; dry the filtered filter residue and then perform ultrafine grinding to obtain hemp milk. hemp dietary fiber;

[0047] (3) Thermal coagulation: Hemp milk is slowly heated to 75°C in a boiling water bath for 30 minutes, then cooled to 45°C in a water bath;

[0048] (4) TG enzyme cross-linking: adding 1‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 60 minutes to solidify;

[0049] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 25min to form;

[0050] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 min...

Embodiment 2

[0051] The preparation of embodiment 2 hemp tofu

[0052] (1) Pre-swelling: select the mildew-free shelled hemp seeds, wash them and soften them with steam, and the steam pressure used is 4MPa;

[0053] (2) Refining: Defining the fully swollen hemp seeds and water at a ratio of 1:5 (without removing slag) to obtain hemp milk;

[0054] (3) Thermal coagulation: Hemp milk is slowly heated to 80°C in a boiling water bath for 10 minutes, then cooled to 50°C in a water bath;

[0055] (4) TG enzyme cross-linking: adding 3‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 90 minutes to solidify;

[0056] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 15min to form;

[0057] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 minutes.

Embodiment 3

[0058] The preparation of embodiment 3 hemp tofu

[0059] (1) Pre-swelling: select the mildew-free shelled hemp seeds and wash them to soften with steam. The steam pressure used is 3MPa;

[0060] (2) Refining: Refining the fully swollen hemp seeds and water at a ratio of 1:5, passing through 100 meshes to obtain hemp milk; drying the filtered filter residue and then superfine grinding to obtain hemp dietary fiber ;

[0061] (3) Thermal coagulation: Hemp milk is slowly heated to 77°C in a boiling water bath for 15 minutes, and then cooled to 45°C in a water bath;

[0062] (4) TG enzyme cross-linking: adding 4‰ of the total amount of hemp protein to activate TG enzyme (16000u / g) at 50°C in advance, and keeping it at 50°C for 60 minutes to solidify;

[0063] (5) Extrusion molding: inject the curd into the mold, and the pressure is 0.8MPa and pressed for 250min to form;

[0064] (6) Pack the shaped hemp tofu and pasteurize it at 65-85° C. for 20-30 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chewiness | aaaaa | aaaaa |

| elasticity | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com