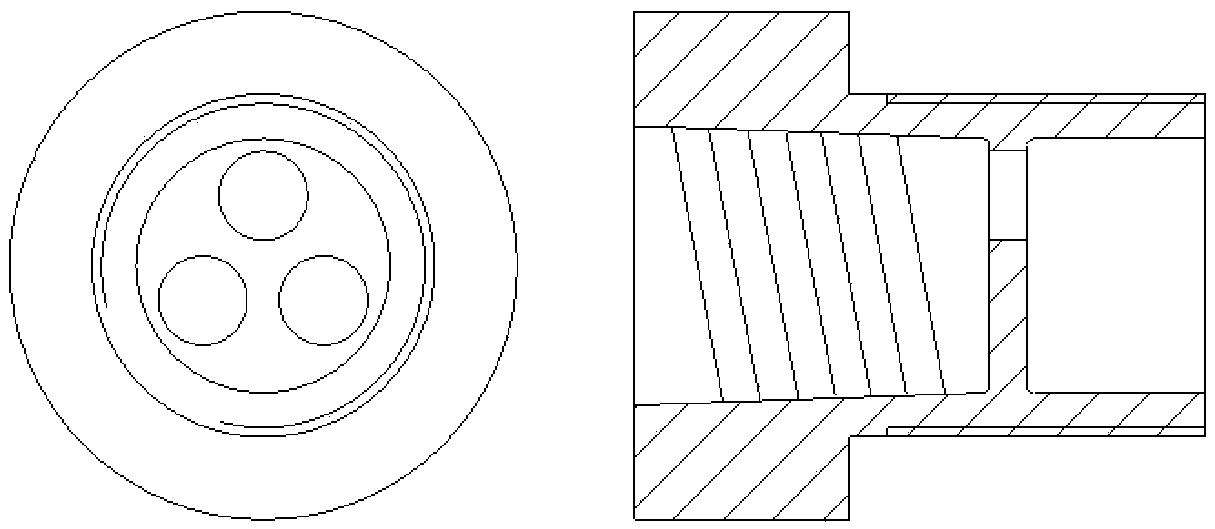

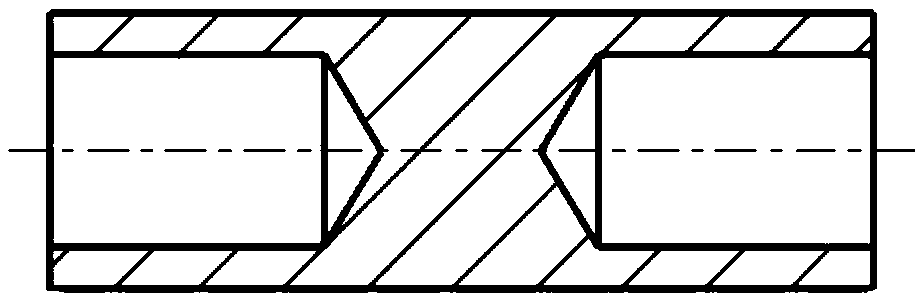

A potted cable sealing penetration structure

A cable and cabin penetration technology, which is applied in the field of potted cable seal penetration structure, can solve the problems of complex mechanical extrusion structure, unreliable reliability, large structure size, etc., and achieve simple, flexible and good adjustment methods. Good electrical connection, pressure bearing capacity and sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The penetrating shell 1 is made of stainless steel, with a total length of 45mm. There are M30 external threads on the right cylindrical wall, and the thickness of the partition structure is 3mm. It is located 6mm to the right of the middle, and there are 3 evenly distributed on it. The through hole is used for the passage and positioning of the cable 5; the left side of the partition structure is a tapered hole with a taper of 1:10, and the right side of the partition structure is a straight hole; the cable transfer device 3 is Copper column, length 15mm, with diameters at both ends A blind hole with a depth of 5mm; the cable 5 is welded with the transfer copper core by brazing; when potting, first insert the 3 cable transfer devices 3 into the 3 through holes of the bulkhead structure of the penetrating shell 1 , the blind holes at both ends of the cable transfer device 3 are respectively welded and fixed to the cables 5 on both sides of the bulkhead 7, and then th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com