A method for promoting liquid-phase water discharge from a gas diffusion layer of a fuel cell

A gas diffusion layer and fuel cell technology, applied in fuel cells, electrical components, battery electrodes, etc., can solve problems such as battery performance degradation, and achieve the effects of reducing difficulty, ensuring concentration, and avoiding flooding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

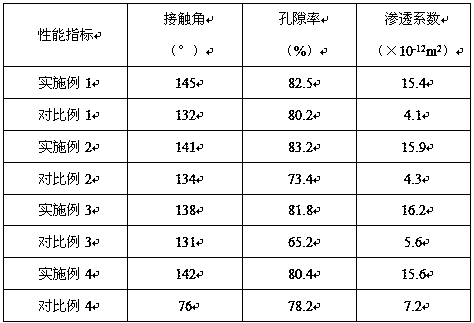

Examples

Embodiment 1

[0029] (1) First inject the phthalocyanine metal complex slurry into the rectangular diversion groove of the fuel cell plate material, so that the slurry is evenly dispersed in the diversion groove, and then cover the part of the polar plate that is not the diversion groove with a mask, Then place it in a vacuum furnace for plasma heat treatment under a protective gas source. After the phthalocyanine metal complex is pyrolyzed, a porous carbon nanotube array is formed inside the diversion groove. Then the mask is peeled off and the diversion groove is rinsed with deionized water. After drying, the polar plate diversion channel with porous carbon nanotube arrays grown on the surface is obtained; the polar plate material is graphite polar plate; in the phthalocyanine metal complex slurry, the metal is iron, and the mass concentration is 28%; the protective gas source is hydrogen , Methane is a mixed gas obtained according to the mass ratio of 1:0.9; the temperature of plasma heat...

Embodiment 2

[0038] (1) First inject the phthalocyanine metal complex slurry into the rectangular diversion groove of the fuel cell plate material, so that the slurry is evenly dispersed in the diversion groove, and then cover the part of the polar plate that is not the diversion groove with a mask, Then place it in a vacuum furnace for plasma heat treatment under a protective gas source. After the phthalocyanine metal complex is pyrolyzed, a porous carbon nanotube array is formed inside the diversion groove. Then the mask is peeled off and the diversion groove is rinsed with deionized water. After drying, the polar plate diversion tank with porous carbon nanotube arrays grown on the surface is obtained; the polar plate material is a copper plate after acid-resistant treatment; in the phthalocyanine metal complex slurry, the metal is copper, and the mass concentration is 20%; The protective gas source is a mixed gas obtained by hydrogen and methane at a mass ratio of 1:0.8; the temperature ...

Embodiment 3

[0045] (1) First inject the phthalocyanine metal complex slurry into the rectangular diversion groove of the fuel cell plate material, so that the slurry is evenly dispersed in the diversion groove, and then cover the part of the polar plate that is not the diversion groove with a mask, Then place it in a vacuum furnace for plasma heat treatment under a protective gas source. After the phthalocyanine metal complex is pyrolyzed, a porous carbon nanotube array is formed inside the diversion groove. Then the mask is peeled off and the diversion groove is rinsed with deionized water. After drying, the plate diversion channel with porous carbon nanotube arrays grown on the surface is obtained; the plate material is a graphite plate; in the phthalocyanine metal complex slurry, the metal is cobalt, and the mass concentration is 40%; the protective gas source is hydrogen , Methane is a mixed gas obtained according to the mass ratio of 1: 1.2; the temperature of plasma heat treatment is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com