Multi-level expansion cavity sprayer

A technology of expanding cavity and nozzle, which is applied to spray devices, spray devices, chemical instruments and methods, etc., can solve the problems of low cleaning efficiency, easily damaged surface, incomplete dust removal, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

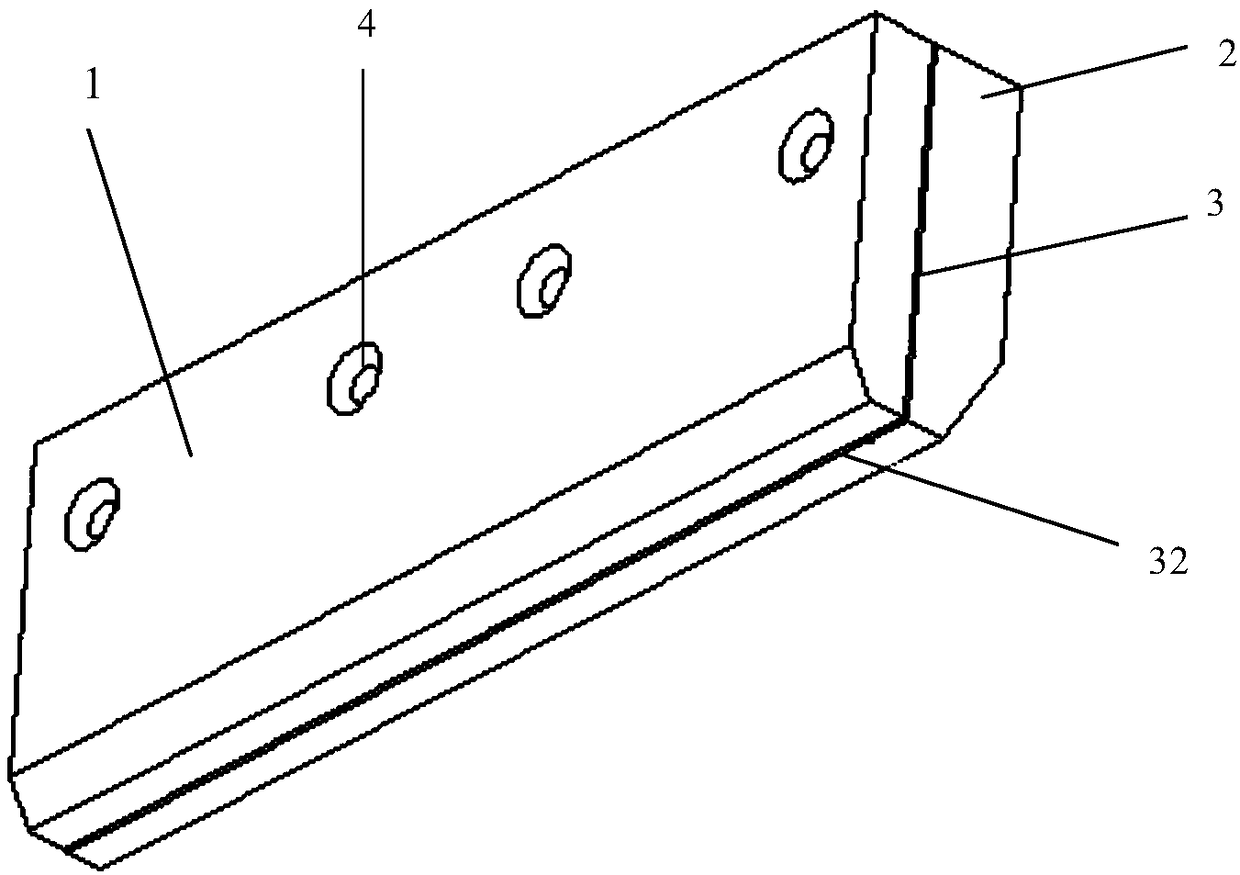

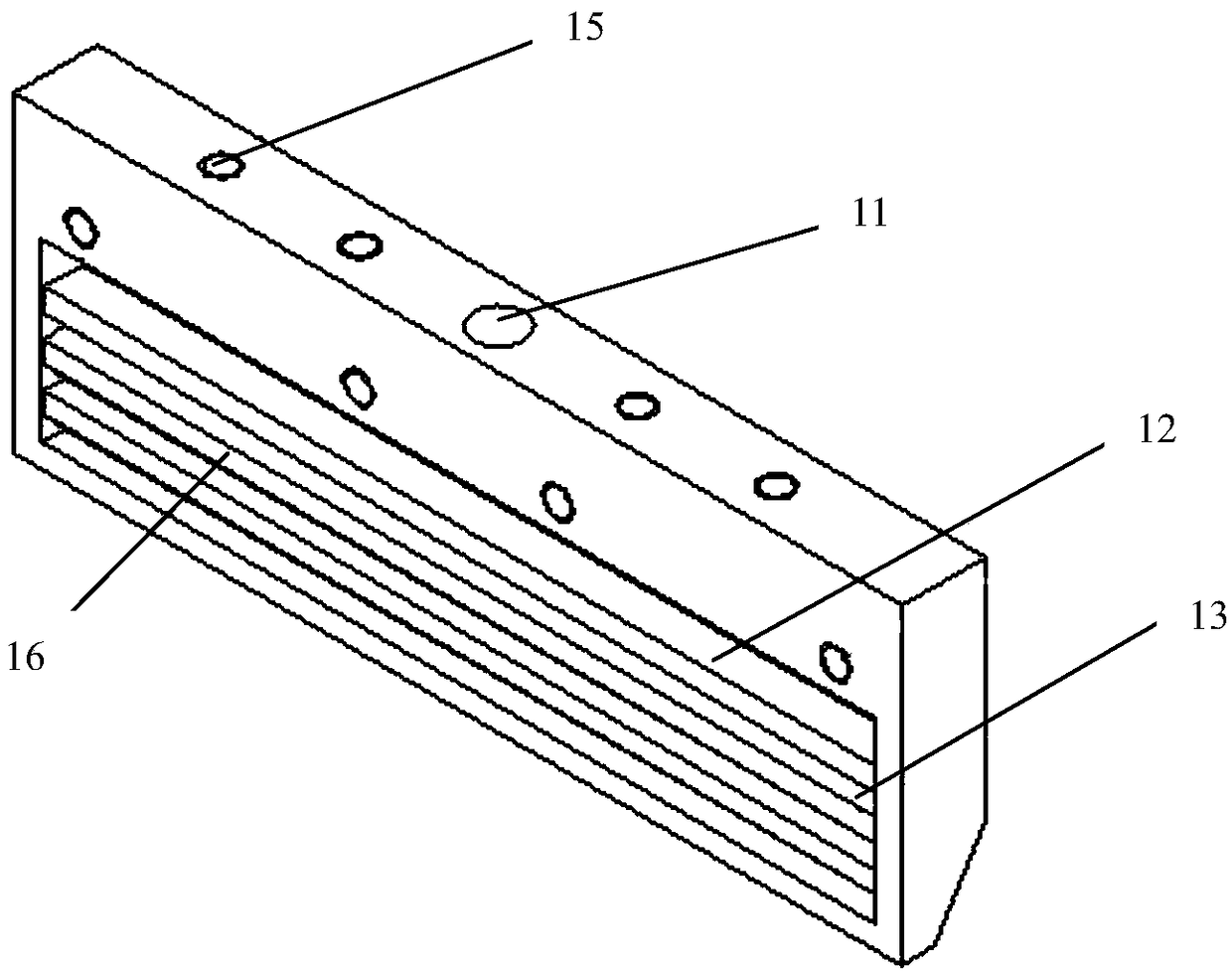

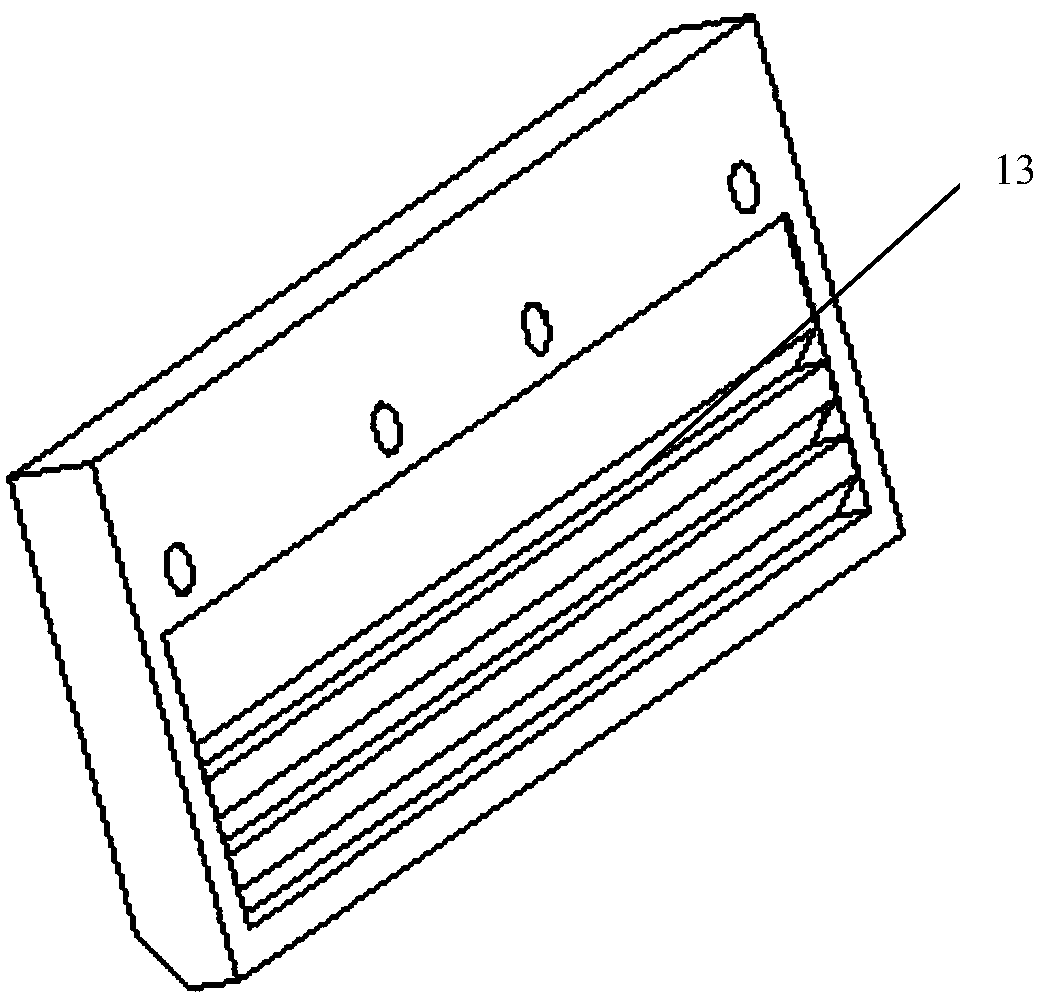

[0016] As shown in the figure, a multi-stage expansion cavity spray head includes a front casing 1, a rear casing 2 and a gasket 3 between the front casing and the rear casing, and the front casing, the rear casing and the gasket pass through The connecting piece 4 (usually a screw) is fixedly connected. The gasket is in the shape of a "door" surrounded by three sides, and the length and width are suitable for the front and rear shells. After the gasket is installed, a certain gap is formed between the front and rear shells as the airflow channel 31, and the opening side of the gasket is used as the airflow channel. Air outlet 32. A rectangular groove is formed on the side of the front housing facing the gasket. After the front housing and the rear housing are fixed, the rectangular groove forms an ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com