Silicon oxide-coated high-nickel precursor, modified high-nickel material and preparation method thereof

A precursor, silicon oxide technology, applied in structural parts, electrical components, battery electrodes, etc., can solve the problems of high residual lithium on the surface of high-nickel materials, poor electrochemical performance, etc., to achieve low cost, improve cycle, and improve structural stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

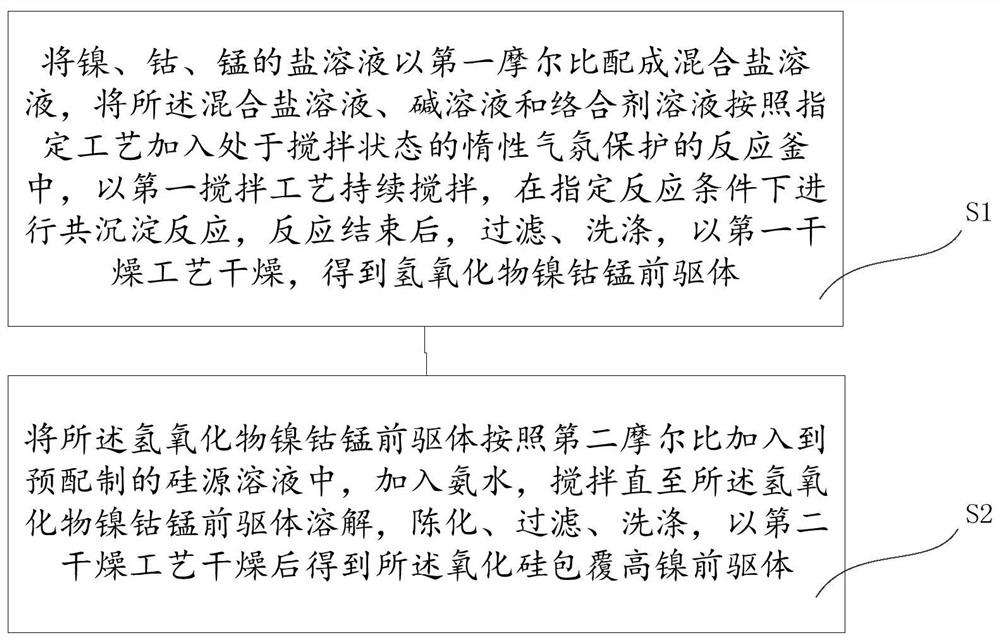

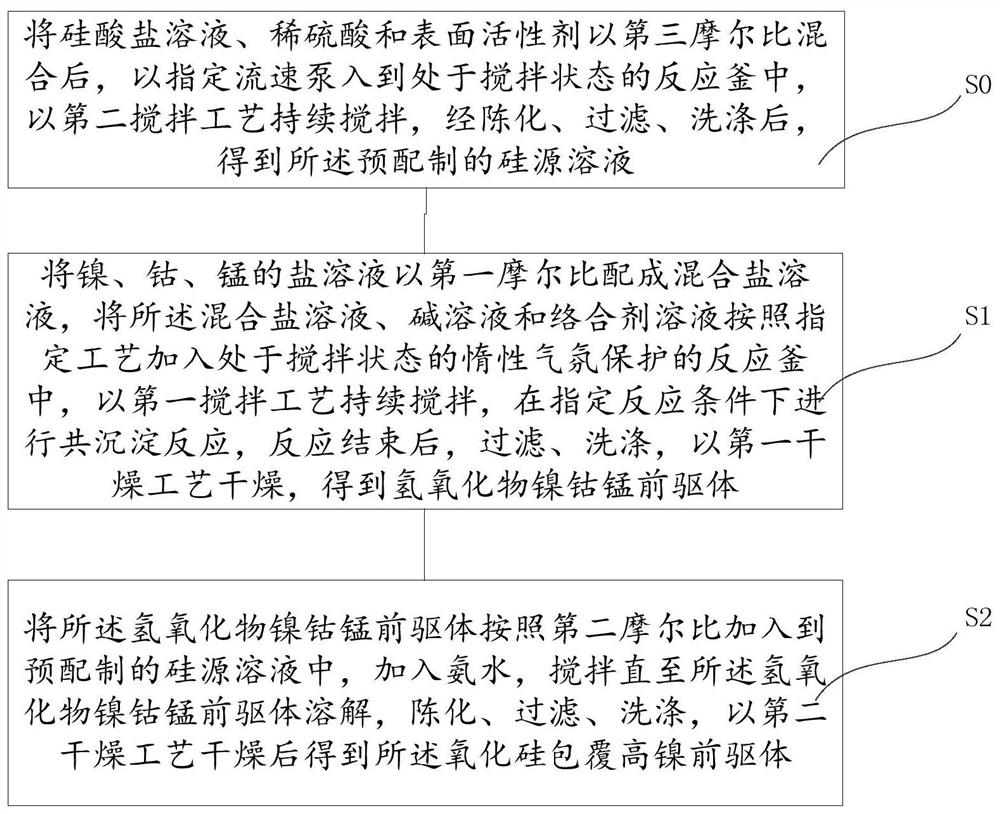

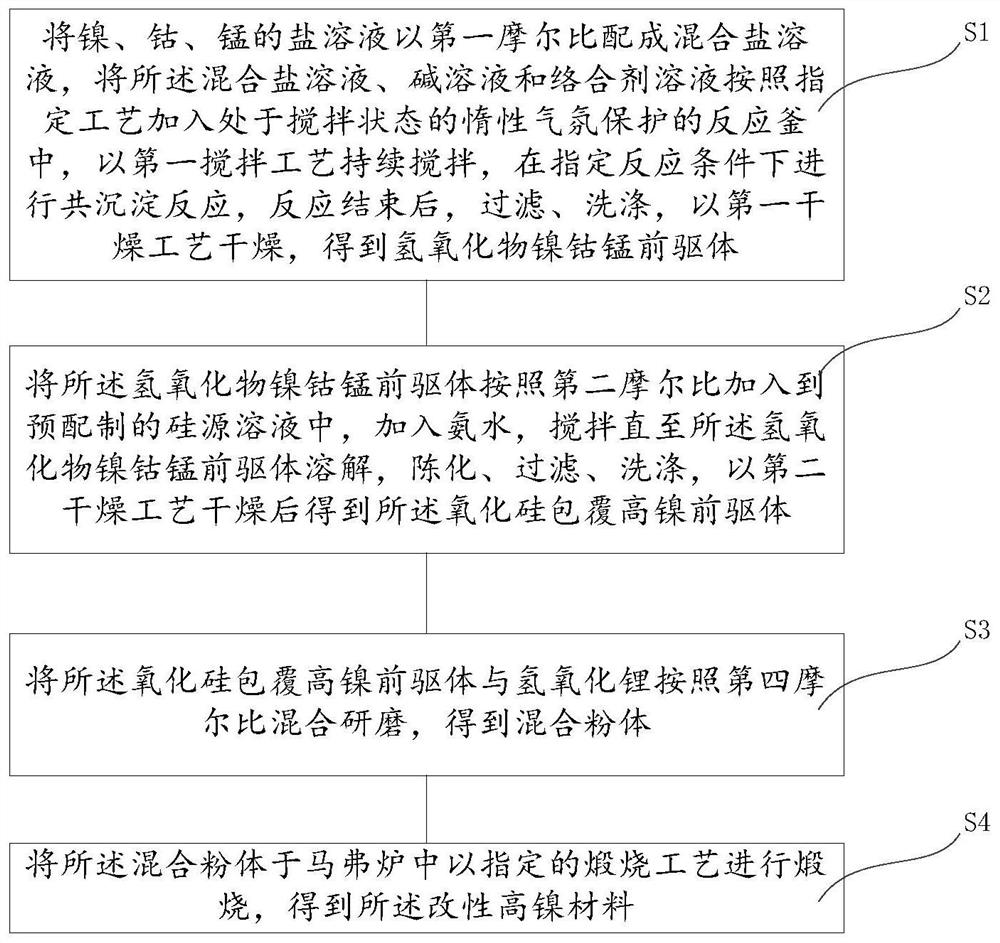

[0030] refer to figure 1 , the embodiment of the present invention proposes a method for preparing a silicon oxide-coated high-nickel precursor, including the following steps:

[0031] S1: The salt solution of nickel, cobalt, and manganese is formulated into a mixed salt solution in the first molar ratio, and the mixed salt solution, alkali solution and complexing agent solution are added to the reaction kettle protected by an inert atmosphere under stirring according to the specified process In the process, the first stirring process is continuously stirred, and the co-precipitation reaction is carried out under the specified reaction conditions. After the reaction is completed, it is filtered, washed, and dried by the first drying process to obtain the nickel-cobalt-manganese hydroxide precursor;

[0032] S2: Add the nickel-cobalt-manganese hydroxide precursor to the pre-prepared silicon source solution according to the second molar ratio, add ammonia water, stir until the n...

Embodiment 1

[0060] Preparation of silicon oxide-coated high-nickel precursor:

[0061] Step 1: Dissolve 2.842g of sodium silicate in 2.842g of water to form an aqueous solution of sodium silicate, add the aqueous solution of sodium silicate to 0.1mol dilute sulfuric acid, stir for 4 hours, then add 0.2g of surfactant PEG4000 (PEG4000 accounts for silicic acid The molar ratio of sodium is 0.05%), continue to stir at 45°C for 2h, add the mixed solution into the reaction kettle through the pump, control the flow rate to 1mL / min, stir for 4h, age for 4h, filter and wash to obtain the silicon source.

[0062] Step 2: Take nickel sulfate, cobalt sulfate, and manganese sulfate with molar weights of 8mol, 1mol, and 1mol respectively, and make 1mol / L mixed salt solution; mix 10L 1mol / L mixed salt solution with 8.5L 2mol / L NaOH The solution was added to the reaction kettle under the nitrogen protection atmosphere, and the pH value of the co-precipitation reaction in the reaction kettle was stabiliz...

Embodiment 2

[0065] Preparation of modified high-nickel materials.

[0066] Steps 1 to 3 are the same as Steps 1 to 3 in Example 1.

[0067] Step 4: Mix the silicon oxide-coated high-nickel precursor obtained in step 3 with 10.5mol lithium hydroxide (the molar ratio of lithium hydroxide to silicon oxide-coated high-nickel precursor is 1.05:1), grind, and heat up The temperature was raised to 450°C at a rate of 5°C / min, and the constant temperature was maintained for 4 hours; then the temperature was raised to 650°C at a rate of 5°C / min, and the constant temperature was maintained for 2 hours to obtain a modified high-nickel material.

[0068] The obtained modified high-nickel material was prepared as an electrode and assembled into a button battery for research on lithium storage performance. Among them, the mass ratio of modified high-nickel material: conductive carbon black: PVDF is 90:5:5, the diaphragm is Celgard2300, and the electrolyte is 1MLiPF 6 (EC:DEC:EMC=1:1:1, volume ratio), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com