Concrete filled steel tube support connecting device

A technology of steel pipe concrete and connecting devices, which is applied in the direction of construction and building construction, and can solve the problems that the connection between longitudinal force and radial force is difficult to achieve balance, the stability of on-site construction connection cannot be guaranteed, and the stability is difficult to achieve an ideal state. To achieve the effect of ensuring the safety and stability of the connection, facilitating on-site construction and pouring, and the connection tension is stable and reliable

Pending Publication Date: 2018-12-28

JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The connection of the current steel pipe concrete support is generally relatively simple, and only rely on the connection of concrete or steel pipes for rigid connection. The connection of radial force is difficult to achieve balance, and the stability and on-site construction connection cannot be guaranteed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

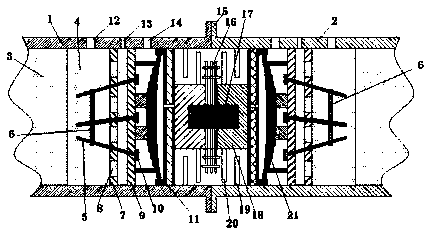

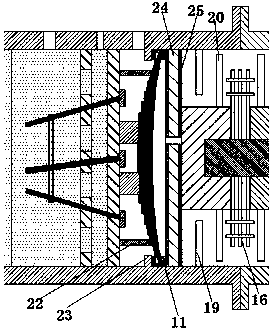

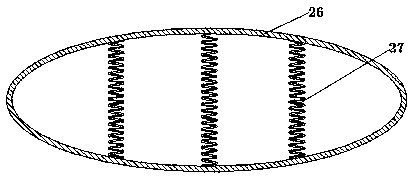

The invention discloses a concrete filled steel tube support connecting device. The concrete filled steel tube support connecting device can facilitate in-site construction casting and achieve stablyconnection of a concrete filled steel tube support. During connecting construction, a worker only needs to mount parts such as anchor rods of a positioning and tensioning module I and a positioning and tensioning module II, then extends the positioning and tensioning module I and the positioning and tensioning module II into the steel tubes of the concrete filled steel tube support respectively, clamps a connecting module between the positioning and tensioning module I and the positioning and tensioning module II, welds axial connecting modules and fills in concrete grout to complete a connection process. The concrete filled steel tube support connecting device is good in connecting stability, high in bearing capacity, stable and reliable in axial and radial connection and tensioning and capable of effectively ensuring the connecting safety and firmness of the concrete filled steel tube support and facilitating construction.

Description

technical field The invention relates to a connecting device for a steel tube concrete support, and belongs to the technical field of steel tube concrete. Background technique Concrete-filled steel tube support is a modern component composed of concrete filled in the steel tube shell. With the help of the binding force of the steel tube shell, the concrete is in a three-way compression state, so that the sandwich concrete has higher compressive strength and deformation resistance. Concrete and steel pipe shells bear axial pressure together, which are used in high-rise buildings, arch bridges, highway overpasses, subway stations, etc. The connection of the current steel pipe concrete support is generally relatively simple, and only rely on the connection of concrete or steel pipes for rigid connection. The connection of radial force is difficult to achieve balance, and the stability and on-site construction connection cannot be guaranteed. Aiming at the above problems, th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): E04B1/38E04B1/41

CPCE04B1/38E04B1/41

Inventor 杨宁赵美霞刘家兴段宇豪李昂锦李飞洪李光耀杨虎威高梓皓于航肖华

Owner JIANGSU VOCATIONAL INST OF ARCHITECTURAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com