Core-shell nanocrystal and preparation method thereof

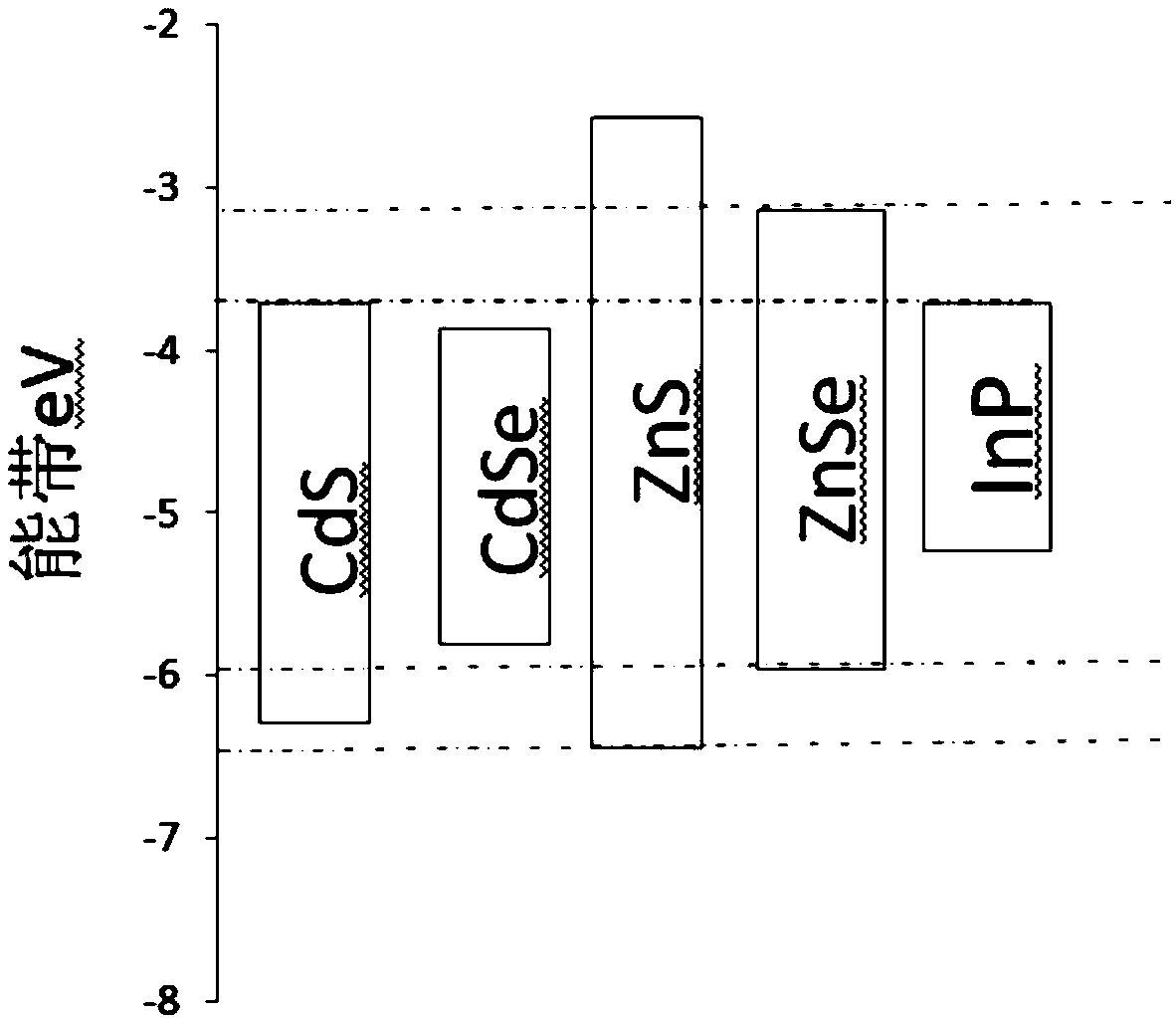

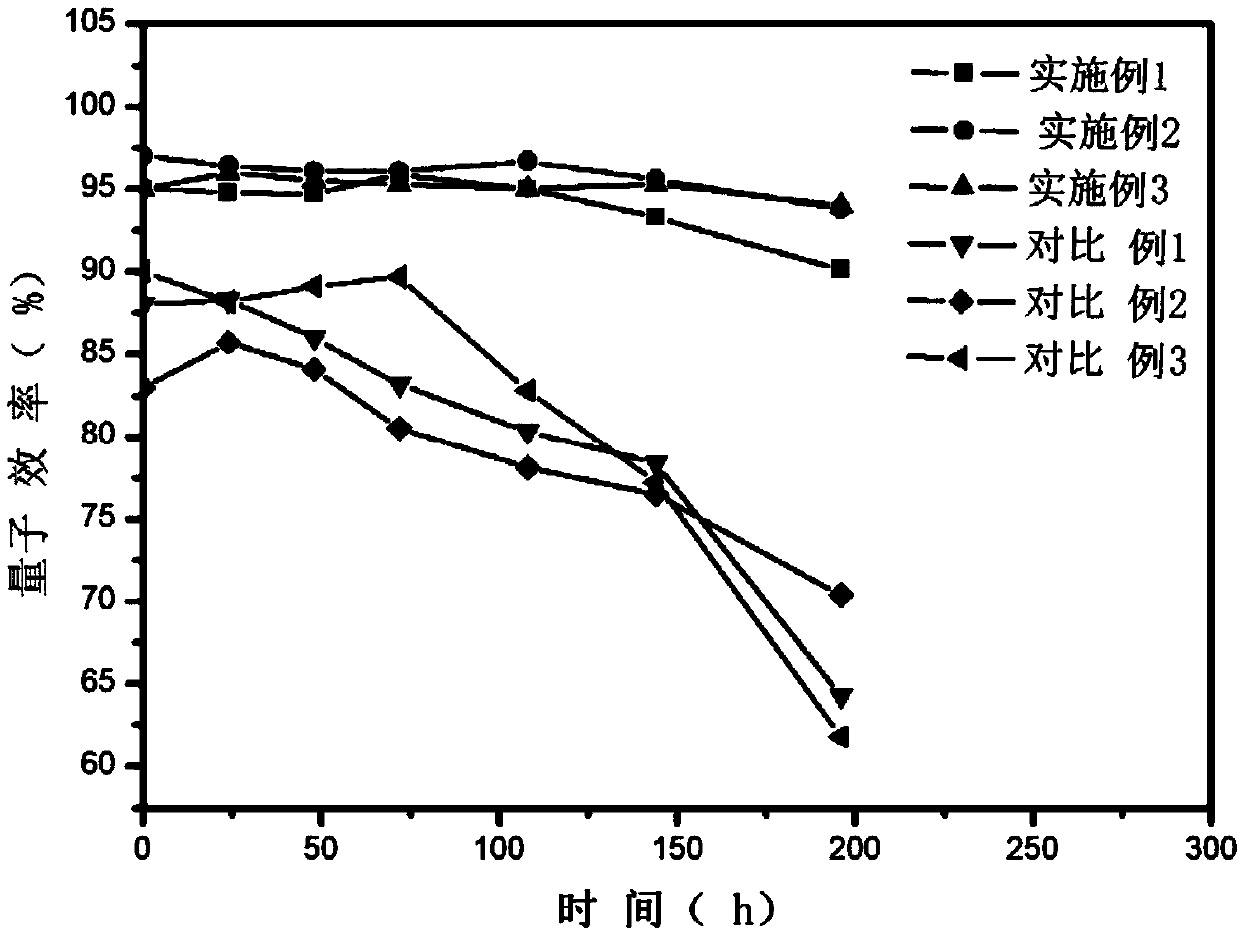

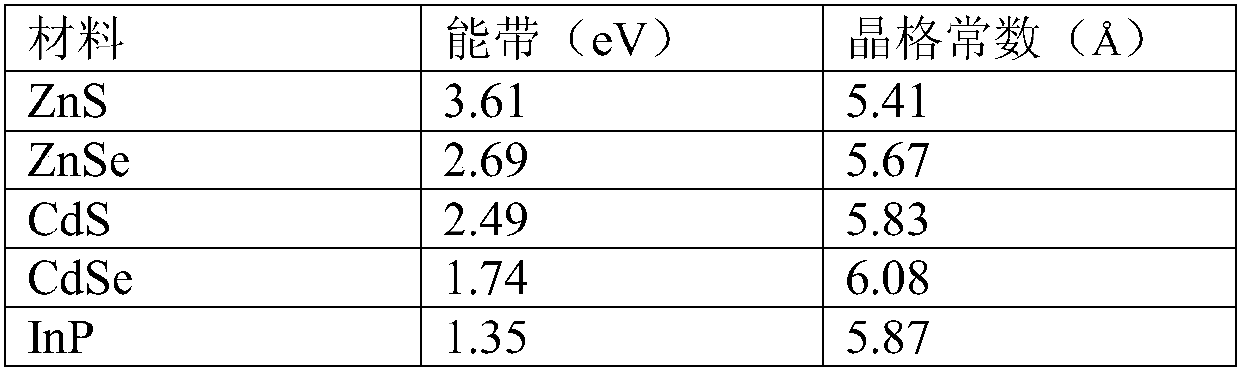

A nanocrystal and core-shell technology, which is applied in the field of core-shell nanocrystal and its preparation, can solve problems affecting the development of quantum dots, surface shell shedding, surface ligand shedding, etc., to reduce interface defects, large energy band deviation, The effect of small lattice mismatch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The embodiment of the present invention also provides a preparation method of core-shell nanocrystals, including:

[0027] Provide cadmium-containing quantum dot cores;

[0028] Coating a transition layer and a shell layer on the quantum dot core, the shell layer includes In x Zn y S 1-x-y Shell, where 0<X<1, 0<Y<1.

[0029] In some embodiments, the following steps are included:

[0030] (1) providing the first liquid phase reaction system comprising the quantum dot core;

[0031] (2) Adjust the temperature of the first liquid-phase reaction system to the first temperature, add a cadmium source and a sulfur source, and react to form a second liquid-phase reaction system. The second liquid-phase reaction system includes a surface coated with a transition layer of cadmium-containing quantum dots;

[0032] (3) Adjust the temperature of the second liquid-phase reaction system to the second temperature, add a zinc source and a sulfur source, and react to form a third l...

Embodiment 1

[0099] 1. Add 10ml of Cd(OA) 2 , 100mlZn(OA) 2 Put 200ml of ODE in a 1000ml three-necked flask, heat up to 120°C and evacuate until there are no bubbles. After obtaining a colorless transparent liquid, blow argon and heat up to 300°C. Rapidly inject 20ml of Se-ODE0.2M at 300°C. After maintaining 300° C. for 30 minutes, the temperature was lowered to complete the reaction to obtain a CdZnSe solution.

[0100] 2. Lower the temperature to 250°C and add 5ml of Cd(OA) dropwise 2 , 0.5ml TOPS, react for 30min, grow CdS layer.

[0101] 3. Cool down to 220°C, add 5ml Zn-OLAM and 0.5ml TOPS dropwise, react for 30min, and grow the ZnS layer.

[0102] 4. Heat up to 300°C, add dropwise 2ml of TOPIn, 5ml of Zn-OLAM, 4ml of TOPS, grow an InZnS layer, and react for 30 minutes to obtain the final product.

Embodiment 2

[0104] 1. Add 10ml of Cd(OA) 2 , 100mlZn(OA) 2 Put 200ml of ODE in a 1000ml three-necked flask, heat up to 120°C and evacuate until there are no bubbles. After obtaining a colorless and transparent liquid, blow argon and heat up to 310°C. After injecting 20ml of Se-ODE0.2M at 310°C, After maintaining 300° C. for 30 minutes, the temperature was lowered to complete the reaction to obtain a CdZnSe solution.

[0105] 2. Lower the temperature to 200°C and add 5ml of Cd(OA) dropwise 2 , 0.5ml TOPS, react for 60min, grow CdS layer.

[0106] 3. Adjust the temperature to 320°C, add 5ml Zn-OLAM and 0.5ml TOPS dropwise, and react for 60min to grow the ZnS layer.

[0107] 4. Adjust the temperature to 320°C, add dropwise 4ml of TOPIn, 5ml of Zn-OLAM, and 6ml of TOPS to grow an InZnS layer, and react for 30 minutes to obtain the final product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com