Vehicle paint and production method thereof

A paint and vehicle technology, applied in the field of vehicle paint and its production, can solve the problems of backward production control technology, low level of paint equipment, lack of innovative technology, etc., achieve excellent outdoor weather resistance, outstanding corrosion resistance, and change the overall structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

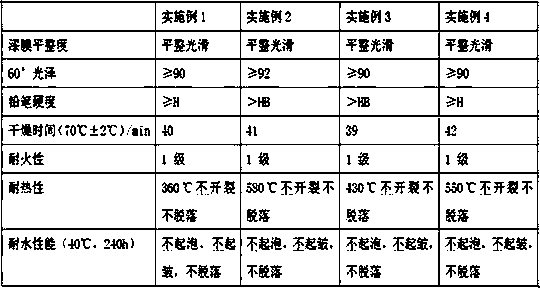

Examples

Embodiment 1

[0048] Coatings for vehicles, comprising the following raw materials in parts by weight: 80 parts of polyester resin; 50 parts of acrylic resin; 11 parts of ultrafine ceramic powder; 20 parts of titanium dioxide; 10 parts of fluorocarbon alkyl monohydric alcohol; 15 parts of nano-titanium oxide; 20 parts of curing agent; 5 parts of ultraviolet shielding agent; 1 part of defoaming agent; 2 parts of leveling agent; 1 part of dispersant.

[0049] The polyester resin is a carboxyl saturated polyester resin with an acid value of 68 mgKOH / g; the ultrafine ceramic powder has a particle size of 0.1 μm; the fluorocarbon alkyl monoalcohol is perfluorobutyl ethanol; the The particle size of the nanometer iron ferric oxide is 16nm; the particle size of the nanometer titanium oxide is 16nm; the defoamer is polydimethylsiloxane.

[0050] The production method of vehicle paint, the steps are as follows:

[0051] (1) Mix polyester resin, acrylic resin and dispersant, stir at 580 rpm, and sti...

Embodiment 2

[0055] Vehicle coatings, including the following raw materials in parts by weight: 90 parts of polyester resin; 60 parts of acrylic resin; 12 parts of ultrafine ceramic powder; 25 parts of titanium dioxide; 12 parts of fluorocarbon alkyl monohydric alcohol; 17 parts of nano titanium oxide; 23 parts of curing agent; 7 parts of ultraviolet shielding agent; 2 parts of defoaming agent; 3 parts of leveling agent; 2 parts of dispersing agent.

[0056] The polyester resin is a carboxyl saturated polyester resin with an acid value of 70 mgKOH / g; the ultrafine ceramic powder has a particle size of 0.3 μm; the fluorocarbon alkyl monohydric alcohol is perfluorohexyl ethanol; the nano Ferriferric oxide has a particle size of 18nm; the nano-titanium oxide has a particle size of 18nm; the defoamer is polyoxyethylene polyoxypropanolamine ether.

[0057] The production method of vehicle paint, the steps are as follows:

[0058] (1) Mix polyester resin, acrylic resin and dispersant, stir at 6...

Embodiment 3

[0062] Coatings for vehicles, including the following raw materials in parts by weight: 100 parts of polyester resin; 65 parts of acrylic resin; 14 parts of ultrafine ceramic powder; 28 parts of titanium dioxide; 14 parts of fluorocarbon alkyl monohydric alcohol; 18 parts of nano-titanium oxide; 28 parts of curing agent; 10 parts of ultraviolet shielding agent; 3 parts of defoaming agent; 3 parts of leveling agent; 4 parts of dispersant.

[0063] The polyester resin is a carboxyl saturated polyester resin with an acid value of 74 mgKOH / g; the ultrafine ceramic powder has a particle size of 0.8 μm; the fluorocarbon alkyl monohydric alcohol is perfluorooctyl ethanol; the The particle size of the nano-iron ferric oxide is 18nm; the particle size of the nano-titanium oxide is 18nm; the defoamer is polydimethylsiloxane.

[0064] The production method of vehicle paint, the steps are as follows:

[0065] (1) Mix polyester resin, acrylic resin and dispersant, stir at 620 rpm, and sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com