Polyvinyl alcohol membrane preparation method for retarding micro-molecule precipitation based on nano silica sol

A technology of nano-silica sol and polyvinyl alcohol film, which is applied in the field of chemical modification of polymer films, can solve the problems of complicated preparation process, limited application and high cost, and achieve the effects of inhibiting migration, low cost and improving precipitation phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

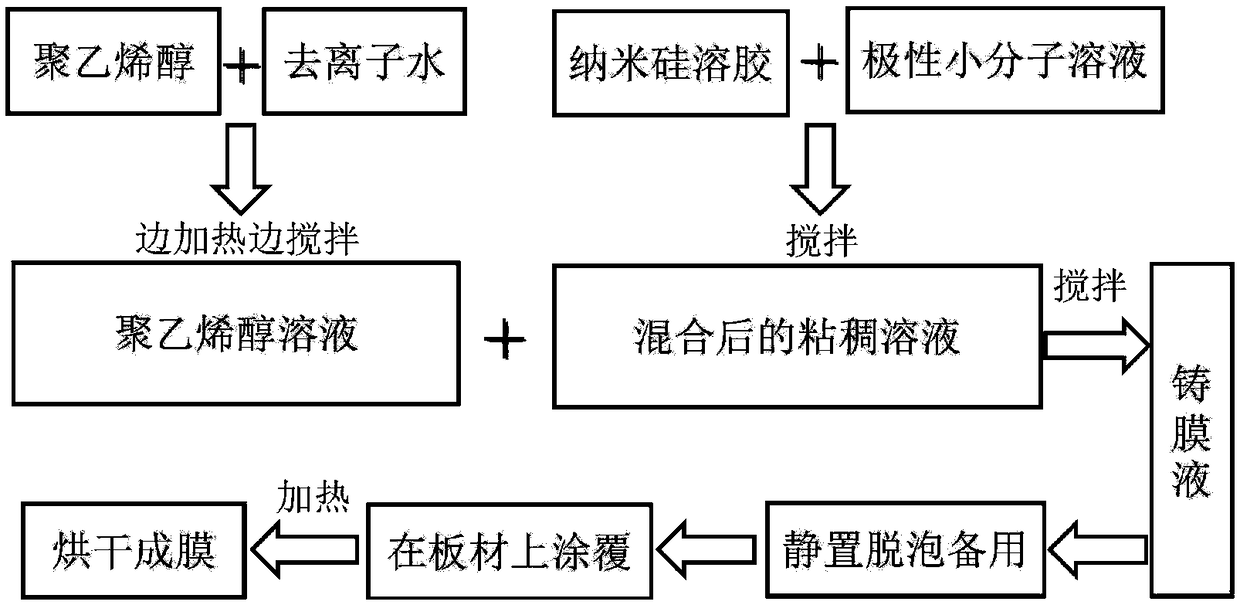

Method used

Image

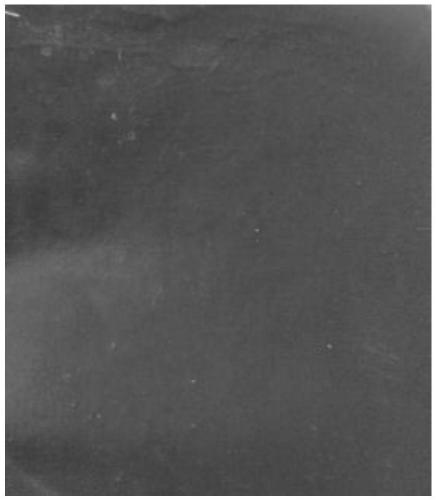

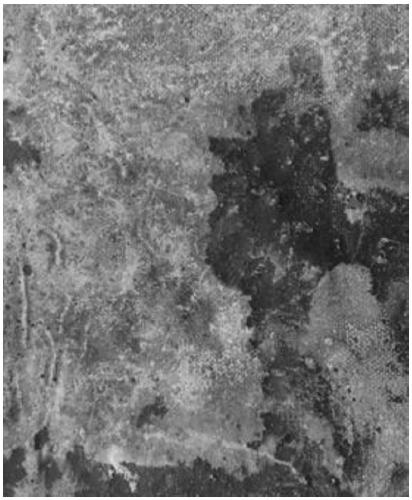

Examples

Embodiment 1

[0026] (1) Take 100g of deionized water, disperse 10g of polyvinyl alcohol in deionized water, and add 3 drops of silicone defoamer to the deionized water, stir with a stirrer at 96°C until the polyvinyl alcohol is completely Dissolve to obtain polyvinyl alcohol solution;

[0027] (2) 1g lithium chloride is dispersed in 10g deionized water, makes lithium chloride solution;

[0028] (3) the lithium chloride solution of step (2) is mixed with 10 g of nano-silica sol with a concentration of 20%, and stirred at room temperature for 1 min to obtain a viscous solution;

[0029] (4) Add the viscous solution prepared in step (3) to the polyvinyl alcohol solution prepared in step (1), and stir at room temperature for 10 minutes to make a casting solution;

[0030] (5) Place the casting solution of step (4) at room temperature for 5 hours for degassing for subsequent use;

[0031] (6) Coat the casting solution after defoaming in step (5) on the plate, and then place the plate in an ov...

Embodiment 2

[0034] (1) Take 100g of deionized water, disperse 11g of polyvinyl alcohol in deionized water, add 4 drops of polyether type defoamer to the deionized water, and stir with a stirrer at 98°C until the polyvinyl alcohol Dissolve completely to obtain polyvinyl alcohol solution;

[0035] (2) 2g lithium chloride is dispersed in 10g deionized water, makes lithium chloride solution;

[0036] (3) mixing the lithium chloride solution of step (2) with 20 g of 30% nano-silica sol, stirring at room temperature for 3 min to obtain a viscous solution;

[0037] (4) Add the viscous solution prepared in step (3) into the polyvinyl alcohol solution prepared in step (1), and stir at room temperature for 20 minutes to make a casting solution;

[0038] (5) Place the casting solution of step (4) at room temperature for 7.5 hours for degassing for subsequent use;

[0039] (6) Coat the casting solution after defoaming in step (5) on the plate, and then place the plate in an oven set at 55° C. for 1...

Embodiment 3

[0042] (1) Take 100g of deionized water, disperse 12g of polyvinyl alcohol in deionized water, add 5 drops of mineral oil defoamer to the deionized water, and stir with a stirrer at 100°C until the polyvinyl alcohol is completely Dissolve to obtain polyvinyl alcohol solution;

[0043] (2) 3g calcium chloride is dispersed in 10g deionized water, makes calcium chloride solution;

[0044] (3) the calcium chloride solution of step (2) is mixed with 30 g concentration of 40% nano-silica sol, stirred at room temperature for 5 min to obtain a viscous solution;

[0045] (4) Add the viscous solution prepared in step (3) to the polyvinyl alcohol solution prepared in step (1), and stir at room temperature for 30 minutes to make a casting solution;

[0046] (5) Place the casting solution of step (4) at room temperature for 10 hours for degassing for subsequent use;

[0047] (6) Coat the casting solution after defoaming in step (5) on the plate, and then place the plate in an oven set at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com